The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

quadrant hinge --- A specialty hinge for use on things like jewelry boxes, this device combines the feature of being totally hidden from view when the lid is closed and the ability to hold the lid open at about 90 degrees. it has a curved element that goes into a deep mortise in the box when closed. It has two L-shaped leaves that have to be mortised and the curved element goes into a deep mortise under the frame leaf. Examples:

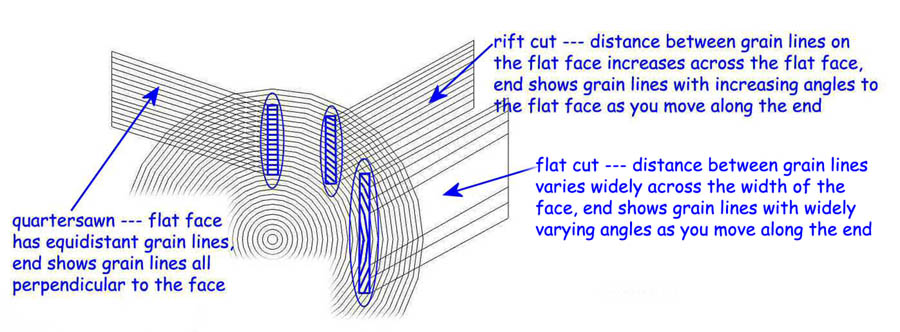

quarter cut --- A log cutting technique in which the log is cut into quarters and then each of those quarters is sliced on one face, turned and sliced on the other face, and so forth. The first cut on each quartered face produces a true quartersawn plank and another one or two that are technically quartersawn, but likely to be much less flaky and the rest of the planks are rift cut. Some reports say that all the planks from quartercutting are quartersawn, but that's nonsense and is a statement that clearly is made only by people who have no concept of geometry. True quartersawn surfaces are perpendicular to the annual growth rings and even slightly less than "true" (a full 90 degrees) quartersawn planks, the angle to the growth rings will be more than 70 degrees or so (the exact amount varies depending on what source you listen to, but it NEVER goes below 60 degrees) and for quartercut planks, that is obviously not the case as you can see in this image that shows quarter cutting. Clearly, as the cutting moves away from each quartered face, the growth rings move farther and farther away from 90 degrees to the face of the plank. Each of the planks after the first one on each face is rift cut. Quartercutting is a more difficult technique than through and through cutting but less difficult than full quartersawn cutting. Quartercutting is used because it produces more quartersawn planks than other commercially viable methods of cutting but it has the significant drawback that it produces smaller and smaller width planks.

quartering --- see quarter cut

quarter matching ---A veneer matching technique that is somewhat the opposite of diamond matching. Four sheets are oriented so that their grain runs generally away from the center point of the four sheets. Because quarter matching is, in practical terms, a pair of book matches, it suffers from the same loose side / tight side matching problem that is described with book matching. There is another form of veneer matching called reverse diamond matching that is similar to quarter matching, but generally reverse diamond matching is done with quartersawn or rift cut veneer whereas quartermatching is done with more complex grains such as burls and crotches. Compare/contrast to other forms of veneer matching. Examples:

quarter measure --- A reference to the thickness of lumber using a quarter inch increments. Thus, 4/4 is a nominal 1 inch, 5/4 is 1 1/4 inches, 6/4 is 1 1/2 inches, etc. In dimension lumber, actual sizes will differ from these nominal sizes.

quarter-round --- molding which resembles a cylinder cut into quarters lengthwise.

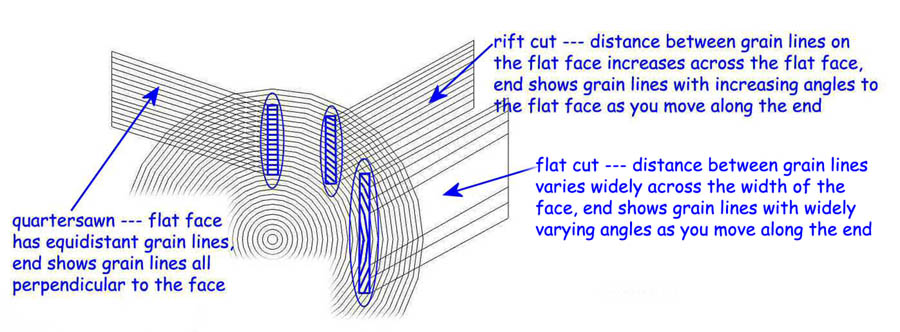

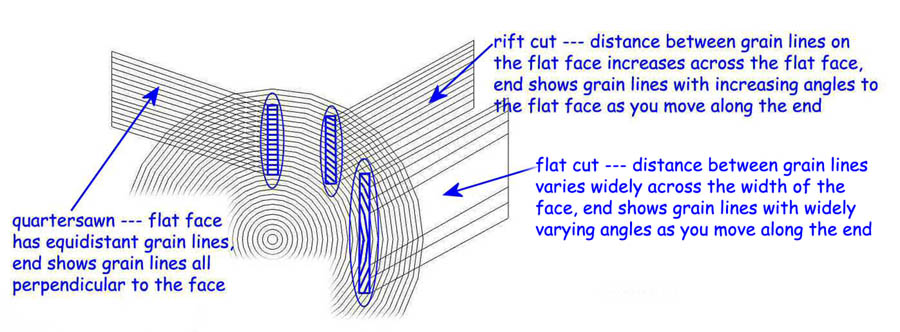

quartersawn --- A board cut with one face parallel to the rays and thus perpendicular to the growth rings. Experts disagree on just how much this angle can drop below 90 degrees and still have a plank legitimately be called quartersawn. Personally, I think it should be as high as 75 or 80 degrees but some experts quote as little as 60 degrees. Quartersawn wood is usually more stable (i.e. less prone to warping, shrinking and splitting) than that produced by other cuts. The point of quartersawn wood is to provide the very attractive flaky figure that it creates, particularly in white oak, lacewood, sycamore, and a few other woods, because of the way in which the medullary rays are cut parallel to the surface of the planks. Full log quartersawing is, however, by far the most wasteful way of cutting lumber as you can see from the figure below; in order to get every plank oriented with its face parallel to the rays, it is necessary to have lots of wide thin triangles of wood that are wasted in the cutting process. Up to 30% of a log can be wasted in this cutting process, far more than any other cutting technique. Because of this massive waste, only species that have prominent ray flakes (such as white oak and American sycamore) are cut this way. Also, it is a very awkward cutting technique because of the way in which the log has to be repositioned between cuts. Below is a pic showing a full log with all true quartersawn cutting; it is my understanding that this technique is NEVER used in commercial lumber operations because it is just too cumbersome and wasteful. Other cutting technique (such as through and through or quarter cutting) will produce a small number of quartersawn planks along with more planks that are rift cut or flat cut.

quarter sheet --- see sandpaper

quarter sheet sander --- A power sander, I believe always an orbital sander, and usually a palm sander that takes 1/4 of a standard sized sheet of sandpaper (thus, obviously, the name). Compare/contrast to other forms of power sander. Examples:

Queen Anne --- A style of furniture that was first made popular in England during the rule of Queen Anne and which was used almost exclusively by early colonial cabinetmakers in America. The cabriole leg is one of the primary characteristics of the Queen Anne style.

quick release mechanism --- Any mechanism that allow for rapid release (and usually application as well) of a set of jaws or other restraining or positioning device. An excellent, and common, example is that found on most bench vises where the mating part of the screw mechanism can be moved away from the tightening screw by a lever next to the handle of the vise, thus allowing the jaws to be moved in and out freely. The most common way of accomplishing this (and this is the method used with bench vises) is the split nut. Once the jaws are in the desired position, the quick release lever is itself released and the screw mechanism once again engages, allowing a pressured clamping with the vise. The concept of "releasing quickly" actually applies to the device itself, not to the object being retained by the device; that is, when the device is holding an object the quick release mechanism might not work because it is under pressure, so the quick release action is often applicable only when the device is not yet in use (and that is definitely the case in the example of a bench vise) and an object under clamping pressure can NOT be release quickly by the quick release mechanism, it has to be released slowly by the clamping mechanism.

quill --- The mechanism on a drill press that holds the chuck which in turn holds the bit. The quill is moved up and down by a quill feed and the amount it is able to move up and down (the quill travel) is a fundamental specification of any drill press.

quill feed --- The mechanism on a drill press that causes the quill (and thus the drill bit) to move up and down.

quill travel --- The distance a drill bit (held in the quill) on a drill press can move up and down. Quill

travel typical varies from 2" to 6" depending on the model.

quilted --- A type of wood figure resulting from interlocked grain. Quilted figure somewhat resembles a larger and exaggerated version of pomelle figure but has bulges that are elongated and closely crowded. A quilted surface looks three-dimensional when seen at its billowy best. Most commonly found in maple, it also occurs in mahogany, moabi, myrtle, and sapele, and less often in other species. A particularly dramatic form of quilted figure is known as sausage quilt. For pics of several quilted woods, see quilted pics. I've seen the quilted look described as bubbles in water under glass, and while that description is very apt for certain forms of quilting (the quilted maple in the pics below, for example) the variety of quilting figure is such that no single description is going to do the job. Here are a couple of composite pics showing various forms of quilt figure. The various forms are NOT generally unique to the particular species with which I happen to have them shown in this presentation), but there are some generalities one finds with experience, such as the fact that quilting will never be particularly strong in oak but it can be amazingly strong in sapele.

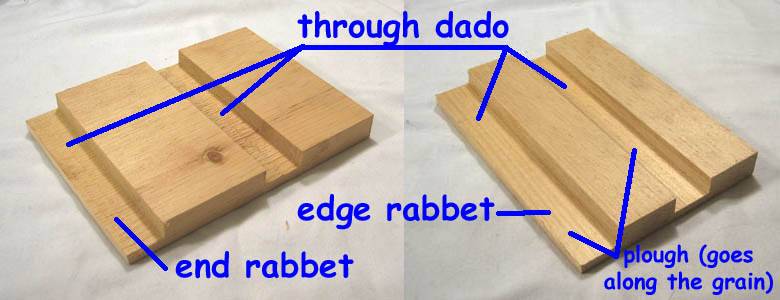

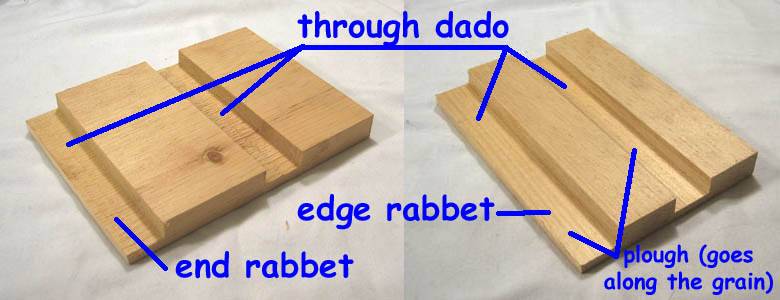

rabbet --- A plough cut that is made along the edge of a board or a dado cut that is made across the end of a board. In either case, this creates an L-shaped channel which can then be used in a joint. If two boards are both rabbeted half way through and one is flipped, they can then be glued up to make a wider or longer board with a seam, or a rabbet can be used at a right-angle joint. When the rabbet is cut along the edge, it is called an edge rabbet and if cut across the end, it is called an end rabbet. For further explication of joinery grooves, see JOINERY GROOVES. Examples:

rabetted --- Containing, or constructed with, a rabbet.

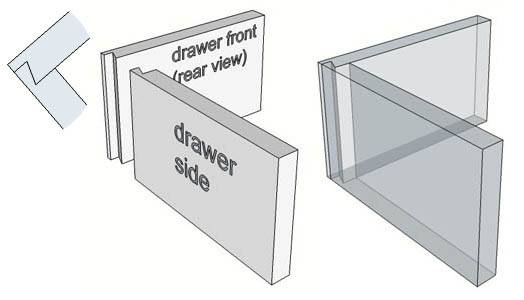

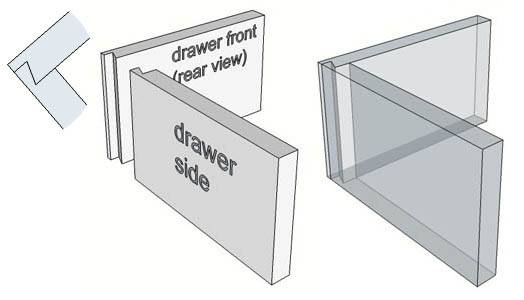

rabbeted sliding dovetail --- This is a variation on the sliding dovetail joint, except that it really doesn't need to slide because it is a half dovetail along an edge at the side of a drawer front, creating a half blind joint that from the front or side looks exactly like an edge rabbet joint. Examples:

rabbet joint --- A joint that uses a groove along the edges or end of one of two planks that are to be joined. The joint can be blind, half blind, or through and there is a version that combines a miter cut. The various versions are shown in this glossary in the following terms:

rack --- [verb] See racking

rack --- [noun] The long flat toothed gear strip in a rack and pinion mechanism.

rack and pinion --- A type of gear mechanism where a cylindrical gear (the pinion) moves against a long straight gear (the rack); in woodworking, this is most often seen used to raise and lower the table of a drill press. Examples:

rack and pinon door hinge --- A particular type of pivot door hinge that uses a rack and pinion mechanism.

racked --- see racking

racking --- (1) To torque a rectangular object in a way such that it becomes a parallelogram under tension. In woodworking, this is seen with a wide end vise that is clamping something on one side and doesn't have a corresponding thickness scrap piece on the other side and thus twists enough to cause the sliding support bars to bind up in the housing. It also refers to what happens when you mis-align a picture frame or cabinetry item while clamping it, or put uneven pressure on it, such that it moves off of true square.

racking --- (2) A method of installing shingles in a "straight up the roof" manner.

racking --- (3) Like many English words, this one has lots of meanings. In addition to the two woodworking related terms above, there are others such as aligning a set of pool balls in a triangular rack, putting items on a shelf (shelves are sometimes called racks), and many others.

racking resistance --- The ability of a panel to resist forces in the panel's plane tending to distort it from its rectangular shape.

racking strength --- synonymous with racking resistance

radial --- This means in a direction outward from the center. As regards wood, this term is primarily used in discussing the direction of the medullar rays. It is one of the three primary planes or flat surfaces of a tree that are used to discuss a number of issues regarding wood. The three planes are radial, tangential, and transverse. A radial plane is any plane that fully contains the axis of the tree; the medullary rays lie along radial planes. When talking about all three planes together, the tangential and radial planes are always considered to be perpendicular to each other, with the transverse plane perpendicular to both of them.

radial arm saw --- A table-mounted power saw that has the blade on a yolk that rides along an overhead beam. The height of the beam can be adjusted and the angles of both the arm and the yolk can be adjusted, making the radial arm saw ideal for compound miter cuts. This type of saw has great flexibility and is preferred by some to the table saw. Sizes range up to 14-inch blades, but the standard hobbyist size has a 10 inch blade. Ripping is done by turning the yolk so that the saw blade is at 90 degrees to its normal cross cutting position, and then moving the workpiece perpendicular to the overhead beam, and as a consequence, it does have the significant drawback that it is not physically possible to rip anything wider than an amount that is usually something less than 2 feet. Examples:

radial drill press --- A drill press with the head mounted on a tube which is laterally and vertically adjustable. This type gives greater throat clearance than a conventional drill press. These are available in both floor models and bench models. Some reports say that bit wobble and lower accuracy can be slight problems. Compare/contrast to floor model drill press. Examples:

radial sawn --- synonymous with quarter sawn

radial shrinkage - Reduction in size of a piece of lumber that occurs across the growth rings (that is, directed from the pith towards the bark), and is caused by drying the wood out either through air drying or kiln drying. Green lumber has so much moisture in it that it contracts in size when dried, and this contraction occurs differently in the three planes of the wood (radial, tangential, and longitudinal). The shrinkage is expressed as a percentage of the dimension of the wood when green. So, for example, if a quartersawn plank were 20" wide when green and 19" wide coming out of the kiln, it would have a shrinkage of 5% and because of the direction, this would be radial shrinkage. Compare/contrast to tangential and longitudinal shrinkage. Radial shrinkage is always less than tangential shrinkage, which is why quartersawn boards have less movement in service than flat cut boards. Longitudinal shrinkage is generally negligible, the other two are not.

radiant heat --- Heat from a source that is installed under flooring or along a baseboard. Flexible tubing is installed in concrete or under the subflooring or run behind a grill along a baseboard. Heated water is fed through the tubing, thus warming the flooring surface, which radiates heat to the entire room. Hot water radiators and steam radiators also provide radiant heat, which is why they are called radiators. Radiators also provide some heat by convection but less than by radiation, and of course if you put your hand on a radiator, it gets hot by conduction. If it's a live steam radiator, I recommend against putting your hand on it.

radiation --- (1) The transfer of heat that occurs due to heat waves moving from a hot body or energy source (such as a fire), through the air, onto a less hot body. All bodies that are above absolute zero degrees radiate heat but cold bodies radiate relatively little and hot bodies radiate more. compare/contrast to convection and conduction.

radius skew chisel --- A lathe tool; a variation on the skew chisel in which the cutting edge is curved, allowing more flexibility in some types of cuts. Examples:

rafter --- Supporting member of a roof immediately beneath the sheathing. Normally rafters are sloping members, because normally roofs slope, but for a flat roof, the members supporting the roof sheathing are still called rafters. I point this out because some definitions say that rafters are ONLY sloping members and that is not correct. Rafters that slope up have a ridge cut at the upper end and a tail cut at the lower end.

rafter angle square --- see speed square (the generic term for the device is rafter angle square but the trademarked term "speed square" is always used instead (just as making a copy on a Cannon copying machine is called "xeroxing" even though technically, the Xerox Corporation can sue you if you say that).

rafter bay --- The area directly under roofing and between rafters. If roof insulation is used, the rafter bays are where it is put.

rafter table --- The layout of a grid of numbers on a framing square that give various useful lengths and cut angles for rafters.

rafter tie --- synonymous with collar tie

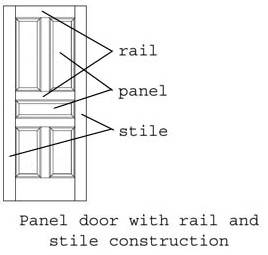

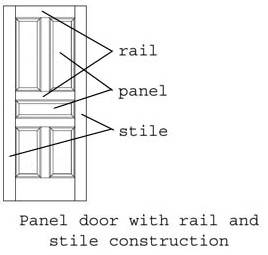

rail --- (1) A horizontal board that runs along the underside of a table or along the underside of a chair or in a paned window or in a divided panel door (see rail and stile construction).

rail --- (2) In general, any flat horizontal member of a wooden construction.

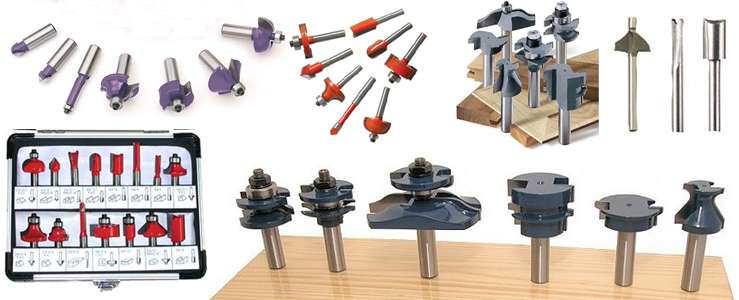

rail and stile construction --- Because wood has a tendency to warp with changes in ambient moisture, a solid wood piece as large as a door, and especially doors to the outside where one side is subject to rain and sun, would be highly likely to warp. SO ... doors are typically constructed in a way that avoids this problem (the general term for the issue is movement in service) and at the same time presents a pleasing look. It is called "rail and stile" construction, and a drawing of an example of a panel door with this type of construction is shown below. The exact techniques of construction are manyfold and there are huge numbers of different style shaper and router bits made for creating the joints and edges of all of the parts.

The "stiles" are the vertical boards and the "rails" are the horizontal boards that join the stiles. Centered between the rails and stiles are the panels, which float. That is, they sit in groves in the rails and stiles with enough extra space that when they expand and contract due to changes in moisture, there is no tension, and thus no cracking or splitting --- that is the fundamental purpose of this construction technique, along with avoiding warping. The rails and stiles are most often jointed with some form of dado joint. There are tons of different combinations of arrangement of rails, stiles, and panels, and what you see below is just one example of many. Smaller doors, such as those used in kitchen cabinets, also commonly use this construction technique.

The terms "rail" and "stile" are used generically for any horizontal (rail) or vertical (stile) support board such as that used on the top/bottom/sides of a paned window, or as a support board in chair construction.

raised barrel hinge --- A type of butt hinge where the (hinge) barrel is bent off to one side so that the hinge can be used on a door that is set back from the edge of the frame relative to the direction of opening in the door. A normal butt hinge COULD be used in most such applicatinos, but that would require a mortise for the barrel that wuold be in addition to, and deeper than, any mortise used for the (hinge) leaf and this hinge obviates that. Examples:

raised grain --- A roughened or fuzzy condition on a wood surface in which the dense late growth is raised above the softer early growth, but not torn or separated. It is usually due to moisture. Some finishing processes call for deliberately attempting to create this condition by wetting down the surface prior to final sanding so that the final sanding will remove the fuzziness before the first coat of finish is applied. It is also a reason why buffing is sometimes necessary after the first coat of a finish is applied.

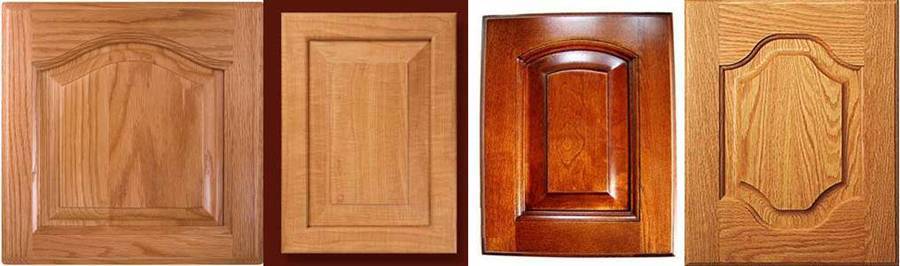

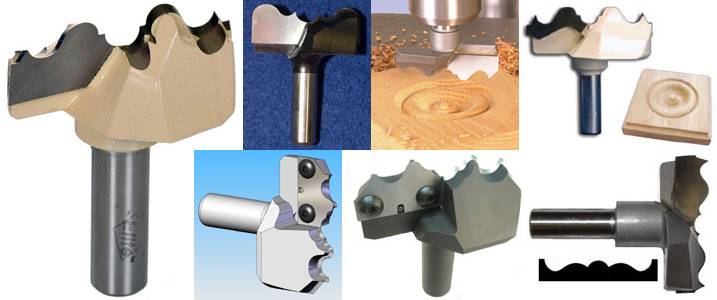

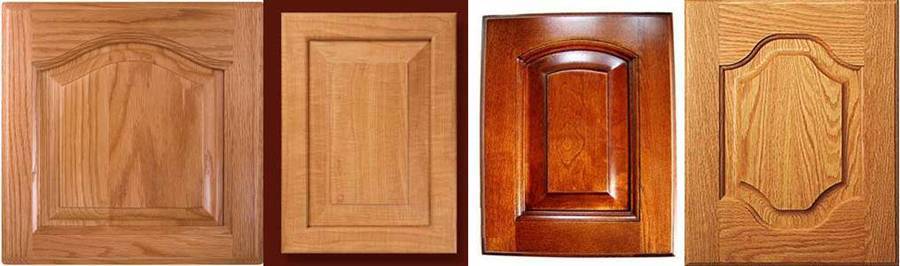

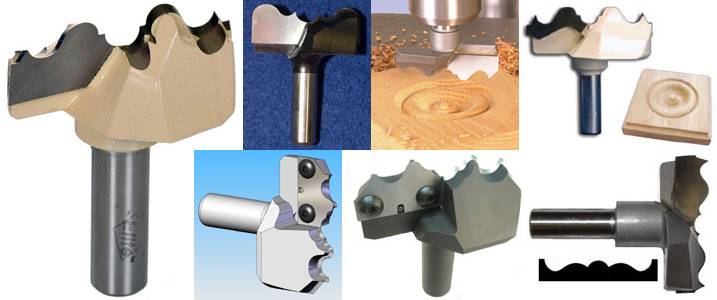

raised panel --- A flat area of wood that is the center of a frame and panel assembly and that has bevels around its edges so that the center part is higher than the edges. That is, the center of the panel isn't actually raised, but rather the edges are lowered, so in very literal terms, it shouldn't be called a "raised panel" but rather a "lowered edge panel". The shape of the panel and the method of lowering the edges varies greatly. There are a wide variety of router bits that are designed to trim the edges of raised panels in various shapes. Examples:

rake --- Pitch or angle. In woodworking, this may refer to the angle at which the leading edge of the teeth are cut on a saw blade or the angle of a roof line from horizontal or the angle between the cutting edge of a chisel and the workpiece.

ram --- synonymous with tailstock spindle

random matching --- A form of veneer matching most often used on wall panels; the technique is to NOT match, or deliberately mismatch, veneer sheets so as to simulate lumber planking. It is sometimes the only possible technique where there is large variation in grain and color from one sheet to the next.

random widths and lengths pack --- synonymous with short pack

rare --- see conservation status

rasp --- A long and flat steel tool with a wooden or plastic handle, very similar to a file but with raised teeth. Although rasps can be used for soft metals, they are primarily designed for shaping wood. Like files, some rasps come in many shapes, with some flat on both sides, some rounded on one side, and so forth. Small curve-ended rasps are called rifflers. Historically, rasps existed before files. Examples:

ratchet --- [verb] To move something by small amounts in only one direction (linear or rotary).

ratchet --- [noun] A mechanism consisting of a toothed wheel or rack engaged with a pawl that permits it to apply force in only one direction (it spins freely in the other direction), either linearly or rotationally. Numerous tightening devices, such as some forms of socket wrenches, use ratchets. In fact, socket wrenches are sometimes called ratchets, although that's pretty sloppy usage. Micrometers use a ratchet mechanism to do the final fine-adjustment.

ratchet wrench --- A term that is sometimes applied to box wrenches and combination wrenches when they have a ratchet mechanism (which they do not always have).

rat-tail --- not synonymous with, but explained along with feathercrotch

rat tail file --- A file that is cylindrical rather than flat, and normally tapered. Used to smooth the edges of holes and other concave curves in metal. Examples:

ray --- see medullary rays (technically, "Medullary ray" is a subset of all rays, but in actual practice, "Medullary ray" is used to refer to all rays.

ray flake --- The appearance of medullary rays created when wood with large rays is quartersawn. Also called ray flecks, and wood with this figure is called flaky; or "flecky". Shown in the composite pic below are several different woods, showing some of the variety that one can find. To see more ray flake pics, click here: ray flake pics

ray fleck --- synonymous with ray flake

razor blade --- A strong, thin steel blade with an extremely sharp edge. In woodworking, these are used mostly in utility knives. The original shaving razor blade was a 2-sided blade and those are still in use but not in woodworking, where the version used is the more recent "safety razor" which has only one side sharpened and a stiffener on the other edge. Also used in woodworking are triangular-edged versions and even long series of snap-off blades, all of which go in utilities knives. The rectangular version also is used in a scraper called a razor blade scraper. Examples:

razor blade scraper --- A scraper designed to remove paint (or glue drops or putty smears, and so forth) from glass; it uses a razor blade (thus the name) and is too sharp to use on wood surfaces. Most models have a slide that allows one to control the amount of blade exposed and also to retract the blade totally when the device is not in use. This should not be confused with a paint scraper which is designed to remove old paint from wood or metal. Examples:

razor mottle --- A form of wood figure (specifically, a form of mottle figure) in which there are very strong sharp lines and some regularity to the pattern. The distinctions among the terms basket weave, block mottle and razor mottle are often somewhat subjective and/or misapplied. To see more pics of razor mottle, click here razor mottle pics. Examples:

reaction wood --- Wood that has different characteristics than normal wood because it is formed a process in which trees bend and grow in abnormal ways due to external stresses. Think about the kind of tree that you often see on the bank of a river where the tree protrudes almost horizontally out from the river bank and then curves upward into a bole that grows straight up in the air. Such trees start off growing straight up but lean over as the bank erodes and/or cannot support their weight as they get bigger. Then their root system gives them enough support to not fall out of the bank and they take the normal path of growing plants and head for the sky. This leaves a "crook", like the crook of your elbow (and NOT to be confused with the crook that is a drying defect). In softwood trees, the lower portion of such a crook takes on particular characteristics and is called compression wood and in hardwood trees, the upper portion of such a crook takes on particular characteristics and is called tension wood.

Reaction wood is not JUST a response to gravity; it also occurs when branches are weighed down by snow for long periods and it can occur in trees that are in an area that has strong prevailing winds and have to brace themselves against it. Reaction wood, particularly tension wood, is more prone to case hardening than normal wood, takes stains and finishes differently than normal wood, and is to be generally avoided for those reasons. Unfortunately, it isn't always easy to spot reaction wood in a cut plank since the changes can be visually subtle and do not often cause any noticeable changes in the wood's figure.

In doing research for this glossary, I attempted to find out what I could regarding the characteristics of the upper side of a softwood tree that has compression on the lower side and of the lower side of a hardwood tree that has tension wood on the upper side. I was not successful and if anyone can point me to an authoritative source on either of those topics, I will be grateful. My assumption for now is that these areas do not differ significantly enough from the surrounding wood to merit particular discussion. I find that a little surprising, but hey, I'm easily surprised.

reamer --- A metal-working tool that is rarely used by woodworkers except in a particular one of its many forms and that particular form is the "tapered reamer" which consists of a body that is about 1/2 inch in diameter at the top tapering down to a small tip and with a rod cross piece at the large end acting to form a handle. There are versions that have a screwdriver-style handle but they really are less effective because you can't get as much torque with them and you sometimes need it. The sides consist of sharpened cutting edges. These reamers are used to clean burrs from a drilled hole in metal, or to enlarge a hole in metal, mostly in softer metals such as aluminum, copper, and mild steel. When used to enlarge a hole, they produce a beveled edge because of their taper. True metal reamers have straight sides but are not woodworking tools. Examples of tapered reamers:

rebar --- Short for "reinforcement bar", which is steel rods that are used to add extra structural strength to concrete. Rebar is usually laid in a grid as part of a poured concrete foundation for a house or a concrete road, but you'll also see it used as a circular wrap inside the pouring forms for really large concrete pillars in highway overpass construction.

rebate --- As regards woodworking, this is synonymous with rabbet

reciprocal --- see reciprocating

reciprocating --- Refers to motion that goes back and forth (or up and down) in a straight line. Compare/contrast to circular. There are several saw types (e.g. scroll saw, reciprocating saw, etc.) that have reciprocating blades.

reciprocating saw --- A portable power saw, somewhat similar to a jig saw, and like the jig saw, also sometimes called a "saber saw". Like the jig saw, the reciprocating saw has, and this will come as no surprise at all, a reciprocating blade, but unlike the jig saw, it is not normally used with the blade vertical; because its primary use is cutting tree branches, it is normally used with the blade horizontal, and unlike the jig saw, the handle is at one end of a long barrel-shaped body that can be held with the other hand. Like the jigsaw, it has a plate that has to be held firmly against the workpiece or else everything goes into vibration in an unpleasant way. Both AC and battery operated models are readily available. Examples:

reclaimed --- Lumber that has been salvaged from an existing building for reuse. Also called recycled.

reconstituted Veneer --- A man-made veneer which uses real wood fiber with natural colorants to simulate various color, figure and grain seen in real wood veneers.

recycled --- Lumber that has been salvaged from an existing building for reuse. Also called reclaimed.

red knot --- synonymous with intergrown; a knot that will not fall out of its position in a sawn plank or beam.

reduce --- (1) To use a thinner to cut down on the viscosity of a finishing agent

reduce --- (2) To make smaller, as in "I need to reduce the thickness of this plank".

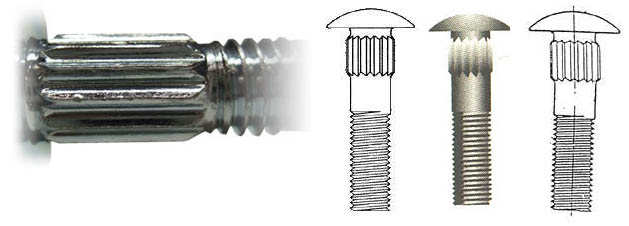

reduced shank --- Refers to drill bits that have a section at the rear of the shank that is smaller in diameter than the bit itself, so that the bit can be used in a drill chuck that would not otherwise be able to hold it. It is very common to have drill bits over 1/2" in diameter have a reduced shank of 1/2" so as to be able to fit in a 1/2" chuck. Examples:

reducer --- synonymous with thinner

reducer strip --- A slanted molding accessory for hardwood flooring, normally used at doorways, but sometimes at fireplaces or to smooth the transition between two different levels in flooring (as in moving from a hardwood floor to a higher or lower vinyl flooring material in an adjacent room. It is grooved on one edge and tapered from one edge to the other so as to help avoid an abrupt transition from one level to another.

reed --- A bead that runs along the length of a spindle turning rather than around the circumference.

reflectance --- synonymous with reflectivity

reflectivity --- The degree to which a surface causes incident light to be bounced off rather than absorbed, expressed as a percentage of the incident light. Reflectivity will vary with a number of factors, the primary ones being the characteristics of the surface and the angle of incidence of the light. Generally, reflectivity is higher for higher angles of incidence. That is, if you have a surface that doesn't seem to reflect a lot of light when you are looking perpendicular to the face, turn it so that you are looking almost parallel to the face and you will see that it reflects much more. There are technical discussions (which I do not yet go into in this glossary) that relate gloss to the percentage of reflectivity at a particular angle.

reforestation --- The establishment of forest crops by artificial methods, such as planting or sowing, on land from which trees were previously removed.

refractory wood --- As a general English language term, refractory means "does not respond well to treatment". As regards woodworking, it means, depending on context, Wood that is difficult to dry, hard to impregnate with preservatives, difficult to machine, and so forth.

relative density --- synonymous with specific gravity

relative humidity --- The ratio, expressed as a percent, of the quantity of water vapor actually present in the air to the greatest amount possible at a given temperature. Technically it is actually based on vapor pressure, not vapor amount, but it is commonly stated as based on amount. Also, it is commonly used as just "humidity", not "relative humidity". Cold air cannot hold very much vapor, so a high relative humidity at a low temperature does not translate into very much absolute moisture. Similarly, air at a high temperature can hold a lot of vapor so a high relative humidity at a high temperature translates into a LOT of moisture. I have read that the ideal range for a home is 35% to 45% relative humidity at about 75 degrees fahrenheit.

relief carving --- A type of carving where the background is cut away, leaving lines and surfaces projecting from the surrounding area. Deeply carved surfaces are sometimes called "high relief" carvings and lightly carved surfaces are "low relief" carvings. The absolute depth is somewhat less significant in determining "low" vs "high" relief as is the depth relative to the height/width of the carving. In a very small area carving, 1/8" might be considered high relief whereas on a much larger carving, it would be low relief. Relief carving is used for anything from simple to very elaborate carvings. If the figures and designs are barely raised from the background and none are undercut, then the carving is called "bas relief". Compare/contrast to chip carving. Examples:

relief cut --- A short straight cut made at right angles to a curved layout so sharper than normal curves can be cut with a jig saw or band saw. That is, in situations where it is desired to make a cut that has a tighter curve than would be possible with a given width of bandsaw blade, relief cuts will let short segments of wood come out of the piece so that the blade can make a tighter curve than it would be able to do inside a solid cut track of its own making.

removable hinge --- This term can refer to either of two types of hinges that allow a cabinet door to be removed without the use of a screwdriver. These are the lift off hinge and the clip on hinge.

rend --- To tear apart violently as in "He saw lightening rend the tree in two".

replaceable tip scraper --- synonymous with multitip scraper

resaw --- The process of sawing lumber in half lengthwise, parallel to the wide face. It is usually, though not always, done through the middle of the board, producing two equal sized boards, each approximately half the thickness of the original but the same width and length. Also, it is usually done on a bandsaw, but can be done on a circular saw. Contrast to ripping.

resawn --- see resaw

residential hinge --- A relatively light-duty architectural hinge" for use in residences (where they are not subject to the kind of heavy use experienced by industrial grade architectural hinges).

residual stand --- A logging term referring to the stand of trees remaining following a tree cutting operation.

resin --- Solid or semi-solid material which has an indefinite and often high molecular weight and can be natural or synthetic. Natural resin is a vegetable substance that occurs in many plants, especially coniferous trees such as the pines. I can confirm that from direct personal experience because every year when I put up the (pine) Xmas tree, where it is a sticky, gunky, thick goo, I get the &^%#$@ stuff on my hands and it's nearly impossible to get it off (It laughs at soap). It is used as the binder and/or film forming agent in finishing products. Resins have a high caloric content and so burn very strongly. Some of the "crackle" you hear in burning pine is the explosive release of gasses as the internal resin catches fire. The resin in pine also causes problems because long after a plank goes into service and is painted, the pine resin (also called pine "pitch") can bleed through the paint or other finish.

related terms:

resin bleedthrough --- a condition in which resin, usually in a knot migrates through a finishing agent (usually paint) and shows up on the surface, or totally discolors the finish. This is particularly prevalent with knotty pine, and it results in an ugly knot-like stain on the surface. Here are pics of a particularly good example, from my own home, showing that this particular closet door frame was made with knotty pine, not the more expensive clear pine. The first pic shows an area with several instances and the 2nd pic shows a closeup of one so that you can see just how obviously it is that this is a wood knot that is showing through. Supposedly, this can be prevented by the use of a knot sealer.

resin canal --- A characteristic of 4 genera in the pine family (pine, spruce, larch and Douglas-fir) consisting of tubular canals lined with living parenchyma cells which exude resin (aka pitch) into the canals. The sizes of resin canals varies among species and this is used for wood identification. They also can cause a gummy mess on freshly cut surfaces. Kiln drying can be used to "set" the resin and greatly reduce the amount of bleed out. Trauma to trees can also cause resin canals to form at the injury site. Some trees that have resin canals develop pitch pockets.

resin glue --- add definition

resin pocket --- synonymous with pitch pocket

resistance to impregnation --- see resistance to preservative treatment

resistance to preservative treatment --- Sometimes a lack of resistance of wood to attack by fungi and insects can be improved from low to average, or even better through preservative treatment. How much a wood can be improved depends on the ability of the wood to absorb and retain suitable preservatives. This varies significantly between species and often even more significantly between sapwood and heartwood of the same species. In many species only the sapwood is permeable enough for treatment. Methods of determining treatability are not standardized, and certainly there is likely to be at least some variability even within a species, so ratings should be taken cautiously.

reverse board and batten --- see board and batten

reverse chucking --- Mounting a face turning backwards so that the other side can be turned. This is most commonly applied to turning bowls, where the inside of the bowl and the upper outside is all turned and then the bowl is reversed into any of various kinds of chucks so that the outside bottom can be turned.

reverse diamond matching --- As the name says, this is the reverse of diamond matching in veneer; the sheets are arranged so that there is something of a "starburst" pattern instead of an enclosed diamond pattern. Some definitions compare this to quarter matching but generally quartermatching is done less as a reverse diamond and more as a complex pattern, as you will see if you look at the illustrations. Compare/contrast to other forms of veneer matching. Examples:

reverse slip matching --- Similar to slip matching in veneer except that every other sheet is flipped longitudinally. This form of matching is used mainly w/ crown cut veneer so as to produce a wave pattern. Compare/contrast to other forms of veneer matching. below are examples using elm and wenge both with crown cut figure.

reverse thread drywall screw --- A screw designed to avoid paper tear in the face of drywall. A screw entering drywall can cause a slight lifting of the paper at the surface and in a severe case can cause small tears in the paper around the screw. These screws have their top several threads reversed so that as the screw goes in the drywall and paper right at the entry point is pushed back down and then the head seats over it. Compare/contrast to drywall screw. Examples:

RGH --- Short for "rough", this is a lumber description meaning lumber not yet planed or surfaced. Compare/contrast to S2S for example.

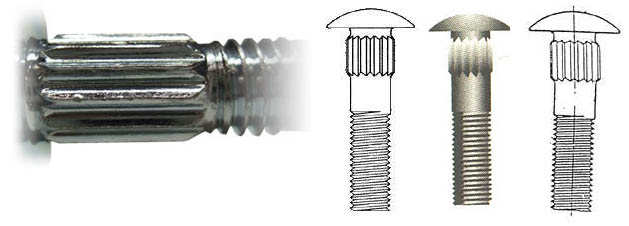

ribbed neck carriage bolt --- A carriage bolt except that rather than the square gripping section at the top of the shank there is a ribbed section that does the gripping. The normal carriage bolt is designed for use with hard metals but this ribbed neck version is designed to be used in wood or soft metal. Examples:

ribbon figure --- synonymous with ribbon stripe

ribbon stripe --- A type of wood figure where there are stripes or ribbons of alternating lighter and darker color that run along the full length of a plank (that is, with the grain). This occurs because of interlocked grain and the stripes are usually at least somewhat chatoyant. If the stripes are broken up and on the order of a foot long, then the figured is called roey. In the pic below is a sheet of ribbon stripe sipo veneer and a guitar with the back made from ribbon stripe African mahogany:

ridge --- see roof ridge

ridge beam --- The top horizontal member of a sloping roof, against which the ends of the rafters are fixed or supported. If the top horizontal member is just a plank, then it is not called the ridge beam but rather the ridge board. See also roof ridge. Examples:

ridge board --- The top horizontal member of a sloping roof, against which the ends of the rafters are fixed or supported. If the top horizontal member is thick, rather than just a plank, it is called the ridge beam.

ridge cut --- The vertical cut at the end of a rafter where it butts up against the ridge beam (or ridge board). Compare/contrast to tail cut.

riffler --- A paddle-shaped file or rasp, usually small and frequently double-ended, used for small, intricate curved work surfaces which will be subsequently sanded or otherwise smoothed (unless, of course, a surface is left rough for artistic effect). Examples:

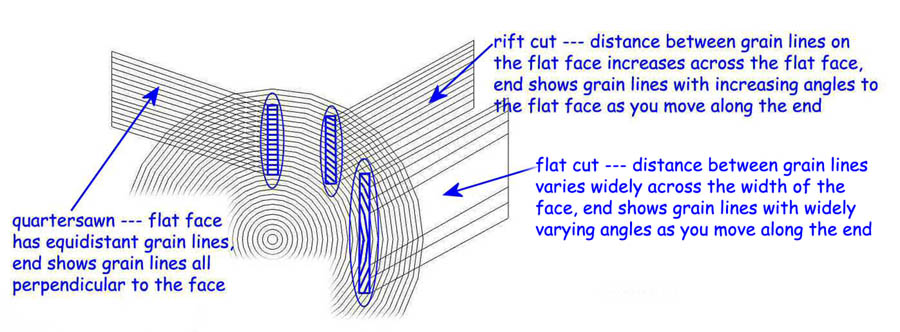

rift cut --- (1) A log cutting technique produced by cutting at a slight angle to the radial to produce very close to the consistent growth ring distances (across the width of the plank) of quartersawn but without the large ray flakes of quartersawn. Rift cut is most frequently used with woods such as white oak that have the potential for heavy ray flakes if quartersawn. Rift cut is used in square furniture legs so the grain looks the same from all sides. Otherwise one side would be flat sawn and the other quarter sawn, which can produce a rather jarring contrast in woods with a strong grain. Riftsawn flooring exhibits less gapping between planks than flat cut flooring during humidity swings due to the fact that expansion and contraction occurs on a significant angle to the floor rather than parallel to it. Quartersawn planks have even less movement in service than rift cut. See the graphic below definition 2 for a comparison of flat cut, rift cut, and quartersawn.

rift cut --- (2) synonymous with quartersawn. I HATE the fact that this usage exists because it causes such confusion with what I consider to be the true and correct definitions of quartersawn and rift cut, but as always I don't get to make the rules, I just report on them.

The exact angle reported differs depending on the authority. Some say 30 degrees to 60 degrees is rift cut and more is quartersawn but some say 45 degrees to 75 degrees is rift cut and more is quartersawn. Personally, I don't think quartersawn should be anything under 80 degrees, and I don't think rift cut should be anything below 45 degrees but then I'm picky. One intelligent authority says about the upper end that basically, hey if the ray flakes show heavily it's quartersawn and if not it's rift cut. That Sounds right to me.

rift sawn --- synonymous with rift cut

rift slicing --- A veneer cutting technique that is primarily used on oak to avoid the appearance of flake. It is achieved in various ways, one of which is by using a "staylog lathe" which cuts with a rotary action. A quarter of the log is fixed to a plate, and the plate is then fixed in an eccentric position relative to the center line of a turning lathe. As the flitch is rotated, it comes in contact with the knife and the angle can be varied so that the wood is cut exactly to produce the very straight rift grain. Rift cut maple, black walnut and cherry are often spoken of, but these are usually the straighter grain portions of plain sliced or quarter sliced logs. Since rift grain is generally the straightest and free from cathedral grain and variations in grain, it is used to enhance verticality and is easily sequenced and matched. Rift sliced veneer is particularly well suited to diamond matching.

right angle --- A 90 degree angle; creates two surfaces that are perpendicular to each other.

right tilt --- see left tilt for a full discussion.

rigid frame --- A form of ceiling construction using a compound structural member made up of studs and rafters fastened with plywood gussets and functioning like an arch. The structure is used as a single construct in place of ceiling joists and collar ties and other ceiling elements. The term refers to both the construction technique and to the compound structural element.

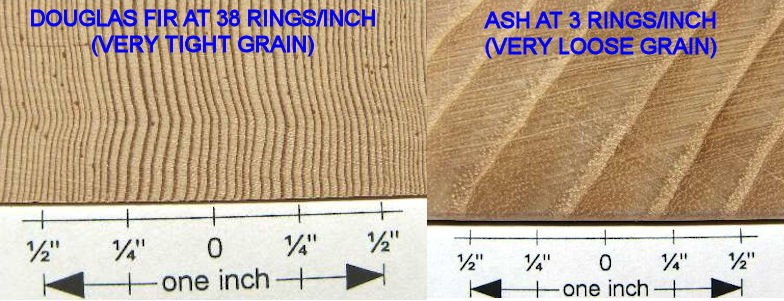

ring center --- Synonymous with cup center

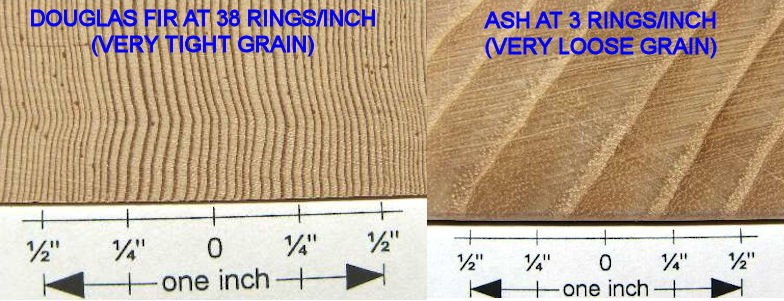

ring count --- A measure of how close together the grown rings in a tree are radially. In the USA this is given as "number per inch", so for example, a fast-growth (loose grained tree might have a ring count of 4, meaning that it took 4 years for the radius of the tree to change by one inch. An old-growth Douglas fir on the other hand might have a ring count of 50 per inch which is VERY tight grained indeed. Ring count has a strong effect on figure and can also have an effect on texture. Examples:

ring failure --- synonymous with ring shake

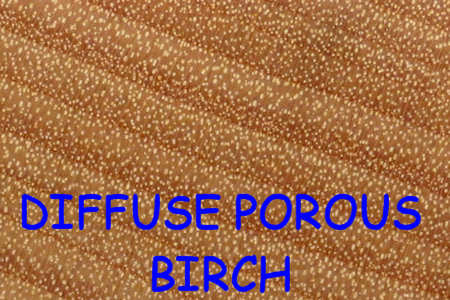

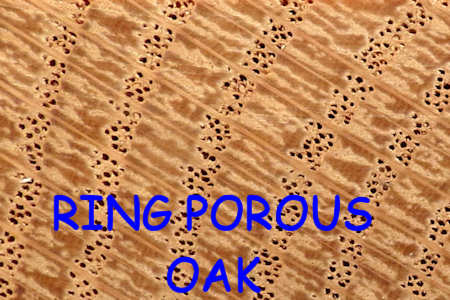

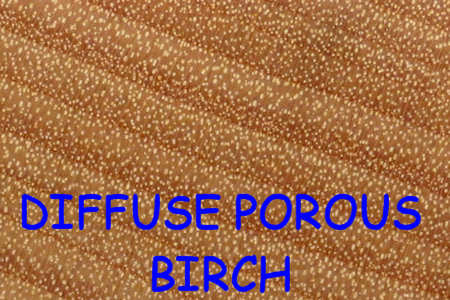

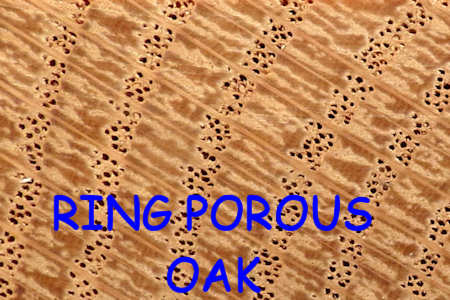

ring porous --- A group of hardwoods in which the pores are comparatively large at the beginning of each annual growth ring and decrease in size, more or less abruptly, toward the end of that early growth area and become small or non-existent in the late growth. Below on the left is a pic of birch, which is diffuse porous, and on the right a pic of red oak, which is ring porous.

rings --- synonymous with annual rings

ring shake --- A form of shake in which the wood separates along the boundary between early growth and late growth. Also called cup shake. Here's an example on the left in kingwood (the ring shake is the circular part of the wood split), and note that this piece also has a small heart shake. To the right of that is an example in a bowl blank that has and entire circle of heart shake.

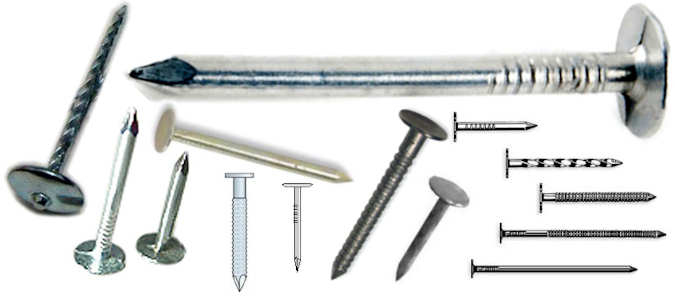

ring shank nail --- synonymous with annular ring nail

ring tool --- A lathe tool; a steel cylinder (ring) with a cutting edge all the way around one end, sharpened with a grind on the inside of the cylinder, and usually mounted via a rod that is brazed or welded to one side of the cylinder so that the inside of the cylinder is totally free for chips to move through as the tool is used to remove material from a lathe turning. The "ring tool" is not at all the same beast as the captive ring tool. Examples:

rip --- [verb] To create a rip cut.

rip --- [noun] A rip cut.

riparian --- Related to or living or or located on the bank of natural watercourse, such as a stream or river or lake or tidewater. For example, Australian river red gum is a riparian tree.

rip cut --- [verb] To cut along (that is, parallel to) the grain of wood. Contrast to crosscut

rip cut --- [noun] A cut that goes along the grain of wood. Note that although technically speaking any cut on a composite material panel is a crosscut, it happens that because wood grain is almost always aligned with the long direction of a workpiece, the term rip cut is sometimes misunderstood to mean "along the length" and in that sense a cut along the length of a panel might be called a rip cut even though it shouldn't be.

rip fence --- see fence

ripping --- Making a rip cut. Ripping a plank produces two planks, each more narrow than the original but of the same thickness and length. Contrast to resawing.

ripple --- A vague wood figure term that might mean curly or it might mean fiddleback.

rise --- (1) In stairs, this is the vertical distance from the surface of one of the treads is a staircase to the surface of the next tread up. In a closed staircase, the rise is fill with a riser and in an open staircase, the space is empty. Compare/contrast to run.

rise --- (2) The vertical distance from the top of the top plate and the top of the ridgeboard (or ridge beam). Compare/contrast to run.

riser --- A vertical plank in a closed staircase. Open staircases don't have risers. The risers are normally attached (usually nailed) to the vertical edges of the stair stringer.

rive --- To tear apart, break into pieces, split, cleave, wrench open, as in "Lightening rived the tree." Sounds like Old English to me; I don't remember ever hearing the word.

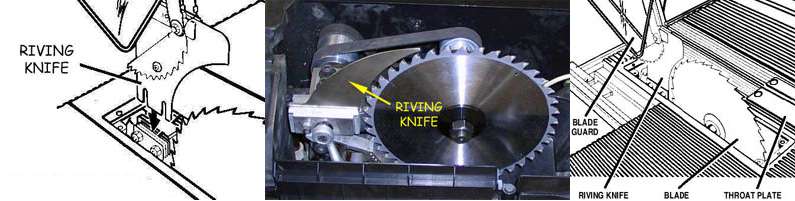

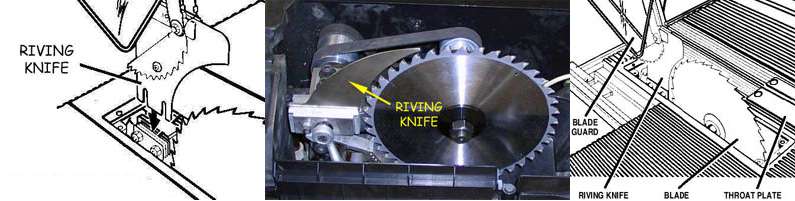

riving knife --- A safety feature on some table saws that is much like a splitter, but much better. Like a splitter, it keeps case hardened wood from pinching in on the blade. Unlike a splitter, the riving knife rides very directly behind the blade (I'm talking 1/4", not several inches) and it's curved to fit the contour of the blade, so it rides very close to the blade along its whole length. Also, unlike a splitter, it raises and lowers with the blade. It does not protrude above the blade, so it doesn't get in the way if you are making a cut that doesn't go all the way through the workpiece passing over the blade. Unlike in America, where woodworkers are allowed to cut off body parts as they see fit without government interference, in the European area, manufacturers are discouraged from producing equipment that is unnecessarily unsafe and the riving knife is required on all table saws and the splitter is looked on as something of an American joke albeit not a particularly funny one.

Robertson screw --- A screw with a head requiring a driver with a square tip (the "Robertson" drive). These are also called square head and socket head. This drive type is used on all kinds of screws but it is particularly popular for flat head screws (that is flush-mount screws), these resist cam-out very well. Personally, I hardly ever use any other kind of wood screw and when I DO use any other kind, I often find that the use is accompanied by numerous loud expressions of words that we would not encourage our children to use. See screw and bolt drive types

rocking --- see rocking cut

rocking cut --- A wood carving term referring to a short sweeping cut. It is the principle way of doing relief carving; the handle of the carving chisel is given a quick twist (rotated) as it is moved forward, slicing out chips. This makes for much cleaner cutting than simply pushing the tool along straight which may tend to tear the grain.

rod coupling nut --- see coupling nut

roey --- A type of figure in wood where interlocked grain produces the appearance of stripes ("rows", thus the name roey, meaning "having rows") of nominally a foot or so long that run along the grain. If the stripes are continuous and straight, the figure is called ribbon stripe. Here's a pic of roey purpleheart:

roll --- [verb] An application technique for putting finishing agents or adhesives onto wood. Rolling is the method of choice for painting walls but it is not often used to paint wooden objects.

roller --- (1) A cylindrical object mounted on a shaft and used to create a smooth motion. Rollers are often used on router bits to provide guides that do not cause wood burn.

roller --- (2) A cylindrical applicator for adhesives and finishing agents. Also called a "paint roller".

roller bearing --- A ball bearing collar on a router bit or spindle shaper bit. Generally put at the top or bottom of the bit (but with multi-part bits it may be in the middle) it is used to keep the workpiece a fixed distance away from the cutters. The roller bearing may be an integral part of a bit or it may be a separate piece that rides above or below the bit on the same arbor. Roller bearings are frequently used with templates where the roller bearing rides against the template and the cutter is thus constrained to cut only as allowed by the template. Also called "rub bearings". Examples:

roller check --- A mechanically-induced crack that occurs when a cupped piece of wood is forced through rollers or other flatteners and the process causes the wood to split along the grain.

roller stand --- An adjustable-height contraption with some form of rollers on top to be used as an extended infeed or outfeed table to support extra long workpieces. Examples:

rondel --- A piece with a shape exactly like that of a coin. Think of a bead on a spindle turning but one that has a rectangular cross section at the outer edge instead of a semi-circular one. The shape is also used for the hand guard on some daggers (think of sticking a knitting needle through a quarter and you have the basic idea of a "rondel dagger").

roof --- The top of a house. Construction techniques and materials can vary, but at a minimum, a normal house roof construction would include rafters, a ridge beam (or ridge board), roof sheathing, and roof shingles.

roof batten --- Small timbers (battens) fixed to the top of rafters and to which roofing material is secured. Often a layer of insulation and/or moisture barrier is put down under the battens. Examples:

roof beam --- A fairly vague term that refers to pretty much any structural member that is used in a roof, such a rafter, collar tie, ridge beam and so forth. To be most technically correct, the term "roof beam" is applied to horizontal longitudinal beams such as the ridge beam. Examples:

roofing --- A somewhat vague term that can be used to refer to the various parts used to construct and cover roofs. This includes the rafters and other framing but more often it means the roof sheathing and/or the roof shingles.

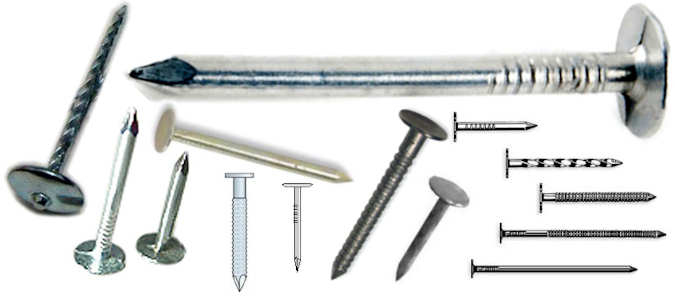

roofing nail --- A nail type with a larger head than common nails so that relatively soft material such as asphalt shingles won't pull through them. These are commonly available and Size depends on thickness of roofing material being nailed down and the thickness of the roof sheathing to which it is being nailed. The shank styles vary greatly, with some being riged, some sprial, etc. Examples:

roofing screw --- A screw, used with a rubber washer that comes with it, to use on roof shingles. The washer is to provide a watertight seal. Such screws are generally either self tapping screws or auger point screws. Examples:

roof louver --- [also spelled "louvre"] A vent that comes up through the roof of a building to allow air to be forced out of the building from bathroom fans, kitchen fans, and so forth. Depending on the shape, these are also called box vents, mushroom vents, airhawks [a brand name], and soldier vents. Roof louvers do not consist of the kind of rows of parallel vents that are exhibited in louvered doors and louvered windows, but rather are a construct of the more general meaning of louver, which is a vented opening that allows for the flow of air but not rain or snow. Examples:

roof plane --- A flat roof area bounded four separate edges (but it may be 3, or more than 4, on a complex roof).

roof ridge --- The highest part of the roof at the meeting of the upper ends of the common rafters. The beam along this ridge is called the ridge beam. Examples:

roof sheathing --- sheathing that is specifically being used on a roof. The roof shingles are nailed to the roof sheathing.

roof shingles --- Rectangles or other shaped pieces of material (actually sold in rolls) that are nailed to the roof sheathing of a house to weatherproof it. They are most often made of a granular material embedded in asphalt. They are laid down in an overlapping fashion to keep rain and snow out. Compare/contrast to siding shingles. Examples:

roof tiles --- synonymous with roof shingles

rooster tail --- see feather crotch

root --- The very bottom portion of a tree, generally underground; a complex series of shoots off of the bottom of a tree that reaches out into the surrounding soil to obtain moisture and nutrients (e.g. nitrogen) that are fed up into the tree to help fuel the tree's growth. Roots on many exotic species are highly subject to root burls which are prized by wood turners and makers of wooden jewelry. When a tree is blown over by a storm, the root system usually drags up a large wad of dirt along with it and this whole mass is known as a root wad. Some trees develop buttressses which are a part-root, part-tree system that goes down into the ground like a normal root, but merges into the trunk of the tree well above ground level and provides mechanical support for the tree in addition to the normal root function of gathering water and nutrients.

root ball --- synonymous with root wad

root burl --- a type of burl that grows on the root of a tree. Such burls can be full of mineral deposits and even whole rocks and pebbles. Even more than "normal" burls (a weird thought, since burls are by definition abnormal) root burls tend to have voids. Like other burls, root burls can be really beautiful in their own way, but they are frequently difficult to work because of the minerals and voids that add to the inherent difficulty in working wood that is as irregular-grained as burl wood.

rootwad --- (also root wad) The ball of tree root and soil that is pulled from the ground when a tree is uprooted. If you've ever seen a large tree totally knocked over by a storm, you know that rootwads can be MUCH larger across than the tree itself, because the root system can be very extensive. I remember once seeing a rootwad that was a tall as the house it was next to but the tree couldn't have been much more than 2 feet in diameter. Examples: (yes, that's a man in the middle pic, but then that's a really big tree --- the pic on the left has a rootwad that is proportionally larger compared to the tree)

ROS --- Random Orbital Sander; see orbital sander

rosette --- A decorative square plate with a cutout circular design centered in the middle and taking up most of the surface. The term is often used for such plates even if the design is not circular. There are rosette cutter drill bits that can be used in a drill press to produce them. Many are both turned AND carved, some are just carved, most just turned. The fancy inlay around the sound hole in an acoustic guitar is also called a rosette. Examples:

rosette cutter --- A shaped cutter that is used in a drill press to cut out rosettes. Examples:

rosin paper --- A particular kind of paper (I have not found any definitive report on its composition) that is laid down on subflooring that is to be covered by wooden flooring, in order to eliminate or at least reduce squeaking by the wooden flooring.

rot --- Also called decay, this is a type of biodegrade characterized by organic decomposition; the breakdown of cells due to attack on the lignin and/or cellulose of the wood by micro-organisms including fungi. There is usually a change in color and always a change in consistency of the wood, including loss of strength and weight. Rot can occur in a section of a living tree and even more so in a dead standing tree, but it is most prevalent in fallen logs, particularly ones where there is substantial ground moisture. At the beginning of the process of rotting, some trees go through a period of spalting. Rot carries the connotation of moist decay and rotten wood is usually a combination of wet and punky. If wood that has rotted dries out before completely disintegrating, the resulting friable wood is called dry rot. When wood is graded, there is a strong limit on how much decay can be present; advanced decay is not allowed in any structural grade of wood. Different types of rot recognized in wood are:

- brown cubical rot --- special form of brown rot

- brown rot --- in gymnosperms exclusively, lignin left behind, cellulose eaten by fungus

- cubical rot --- same as brown cubical rot

- dry rot --- a misnomer; it's the dry remains of brown rot

- soft rot --- partially decayed wood

- white rot in Hardwoods almost exclusively --- all wood is broken down

rotary --- see rotary cut

rotary cut --- A veneer production technique where the log is put on a huge lathe-like machine with a long sharp slicer that runs the length of the log and slices the wood the way paper towels come off a roll. For softwoods, the slices can be up to 1/4" thick for use in plywood, or the more normal 1/42" regular veneer thickness that is also used for hardwoods. Rotary cut is a technique that is only available for veneer, not lumber. The exotic wood bubinga is given a special name, kevazingo (or kevazinga), when it is rotary cut. Many woods (bubinga and others) are rotary cut to produce a wild, swirly figure. Rotary cutting is the most economical method of producing veneer, resulting in the highest yield. That's the good news and it makes this the favored method for cutting thick softwood veneer for plywood. The bad news is that rotary cut sheets have totally inconsistent grain and are pretty much impossible to match in any of the normal veneer matching techniques. On the other hand, they are often so attractive that they can be used quite successfully in architectural panels without using any matching, and they are a favorite of craftspeople for objects such as jewelry boxes. Below is a pic of Douglas fir being rotary cut for plywood and then a pic of kevazingo (rotary cut bubinga).

rotary grinder --- add definition

rotary hammer --- A very heavy-duty version of the hammer drill. The rotary hammer is constructed differently (internally) than the hammer drill and is much more heavy duty and durable and provides a stronger blow. The name "hammer drill" emphasizes that the tool is a drill with a hammer function; the name "rotary hammer" emphasizes that the tool is a hammer that happens to have been created using a device that has an internal rotating mechanism. While the rotary drill is made for drilling in masonry, concrete, etc, the rotary hammer is basically a very small version of a jackhammer and is more likely to be used, as is a jackhammer, for breaking up masonry, concrete, etc. As far as I know, rotary hammers do not come in battery powered versions; this makes sense because they use more power than could be provided by a portable battery for any substantial duration. Examples:

rotary sander --- add definition

rotary tool --- As a generic term in the English language, this refers to any tool that uses a circular motion, but in woodworking, it also specifies a particular tool. The original one of these tools is the Dremel tool and although the Dremel now has competitors, the term "dremel tool" with an implicit (but incorrect) lower case use is more common than "rotary tool". In fact, the only reason for the existence of the term "rotary tool" is to specify a Dremel competitor since they can't very well call their tool a "Dremel tool" even though the rest of us often do. They DO make a point of stating that their attachments work with the Dremel tool, but that's just a backhand way of saying that the Dremel tool attachments will work with THEIR tool. Anyway, for illustrations of a typical tool and attachments, see Dremel tool.

rotten --- Describes wood or other organic matter that has undergone rot.

rottenstone --- A natural abrasive ground from powdered limestone, used as a fine polishing abrasive for finishing agents in woodworking. It has similar applications to pumice, but it is generally sold as a finer powder and used for a more glossy polish after an initial treatment with coarser pumice powder. It is usually mixed with oil, sometimes water, and rubbed on the surface of varnished or lacquered wood with a felt pad or cloth. Rotten stone is sometimes used to buff stains out of wood. Some polishing waxes contain powdered rotten stone in a paste substrate. For larger polishing jobs, rotten stone mixed with a binder is applied to polishing wheels.

rough --- (1) Refers to wood that is coarse textured

rough --- (2) Refers to wood that has been only very roughly surfaced (but which may NOT be coarse textured).

This term can be ambiguous (as in "the plank has a rough surface", which could mean roughly finished or coarse textured, or both). For both definitions, compare/contrast to smooth.

rough cut --- (1)[verb] To cut a workpiece slightly oversize in thickness, width, and/or length, prior to trimming it to final dimensions.

rough cut --- (2)[adj] Lumber that has been rough cut as in (1) above.

rough cut --- (3)[verb] To cut lumber to thickness during an initial milling process, but leaving all surfaces rough.

rough cut --- (4)[adj] Lumber that has been rough cut as in (3) above. Synonymous with rough sawn

roughing gouge --- A lathe tool used in spindle turning for quickly reducing square stock to a round section. It has a semicircular cross section and is ground square across the cutting end. The bevel angle should be around 35° to 45°. A roughing gouge is for spindle work and should not be used for face turning, as the upper edges, which are not swept back like those on a bowl gouge will tend to catch on face turnings. Examples:

roughing out --- The process of using a roughing gouge to bring a rough cut spindle to an approximately cylindrical shape but with a surface that is not yet fully smooth.

roughing out gouge --- synonymous with roughing gouge

rough lumber --- synonymous with rough sawn

rough sawn --- Lumber which is sawn, edged and trimmed but not run through a planer; that is, it has not been surfaced. synonymous with "unsurfaced" and "rough cut". Compare/contrast to dressed lumber.

rough turning --- The lathe process of turning a square cross section turning stick into a round (dowel-like) shape, or turning a rectangular bowl blank into a roughly bowl-shaped object.

round coupling nut --- see coupling nut

round edged lumber --- lumber that is natural edged on both edges.

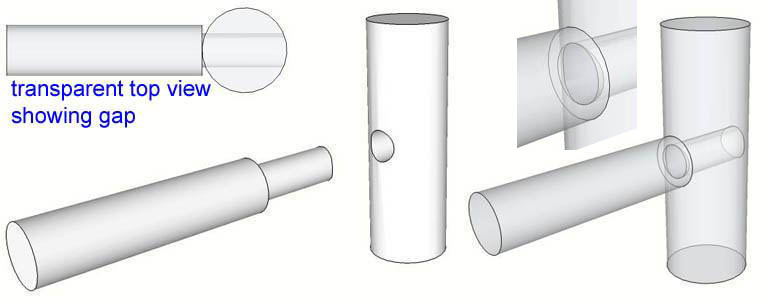

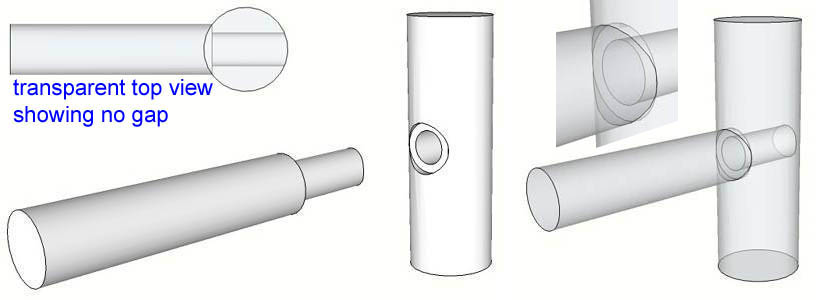

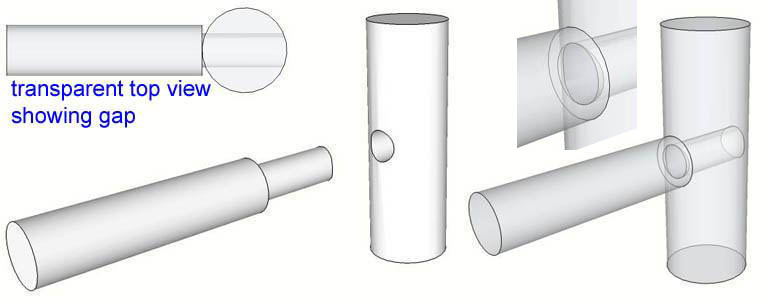

round mortise and tenon --- A standard joint for chair legs with cross pieces, this joint can be done in two fundamentally different ways. The quick and dirty way is to just drill a hole in the receiving piece (usually the leg) and shape the end of the cross piece into a large dowel. The problem with this technique is that it leaves a small, but obvious, gap at the sides of the joint. That is, the top and bottom of the tenoned piece mates perfectly with the mortised piece, but at the sides, the curvature of the mortised piece takes it away from the tenoned piece. A way around this is to first use a Forstner bit or a spade bit to drill a shallow cylinder in the receiving piece that will accept the tenoned piece. Because round tenons are very poor at resisting twisting forces, they should be avoided where possible (but I am NOT suggesting that they not be used on chairs, even though they COULD be avoided even there, albeit only with considerable effort). Examples:

round mortise and tenon without a shoulder cutout

round mortise and tenon with a shoulder cutout

round nose scraper --- A lathe scraper that has a rectangular cross section and a rounded nose used for scraping the work. This tool may be held flat on the tool rest, or sometimes angled to produce more of a shearing action than a scraping action, but you have to be careful when doing that because the sharp edge of the tool will dig into the tool rest, possibly causing the need for more frequent dressing of that surface. The scraping edge of this tool may have the type of grind that is similar to that in the flat nosed scraper in that there is a constant angle to the flat top of the tool, or it may have what is more of a fingernail grind. Most of the examples in the composit pic below are the flat grind but the one directly above the fingernail grind illustration in the lower left corner has the fingernail grind. I use both and find both to be very effective, but the fingernail grind tools are better suited when you want a shearing action instead of scraping because they present a sharper edge to the wood. Compare/contrast to flat nosed scraper. Examples:

round nose side cutting scraper --- see side cutting scraper

round skew chisel --- An extreme extension of the much more common oval skew chisel, this variety is only made by a couple of manufacturers. Like the oval skew chisel, the point of the curved edge on the tool is to facilitate rotating the tool against tool rest for variable slicing angles as it is moved over a variable workpiece surface. Example:

round timber --- timber used in the original round form, such as in poles, posts or bridge beams.

rout --- [verb] To groove or hollow out a wood member by gouging with a cutting tool, most often a router or a hand plane.

router --- A powered cutting tool that is in essence a motor with handles. It has a flat plate on the bottom through which pokes an arbor with a chuck that holds a cutting head, called the bit. Routers are one of the most versatile and widely used of all woodworking power tools. They can be mounted in a table (see router table) which makes them act much like shapers. Conventional routers start cutting at someplace on an edge of a workpiece and proceed from there, but there is a version called the plunge router that allows the cutting bit to be pushed down into the workpiece from any point on the face. Routers are used to make all kinds of joints, decorative cuts (you can do lettering with them), surfacing operations, and more. The number of router bit shapes and sizes is practically unlimited. For good control, the router bit and wood are moved relative to each other such that the bit is moving into the cut; when done the opposite way (rare, but for a particular reason), it is called a climb cut. Examples:

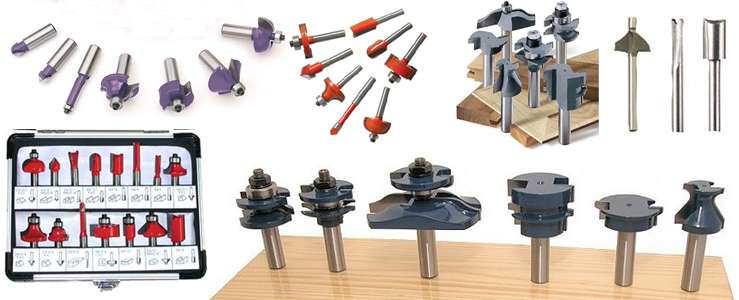

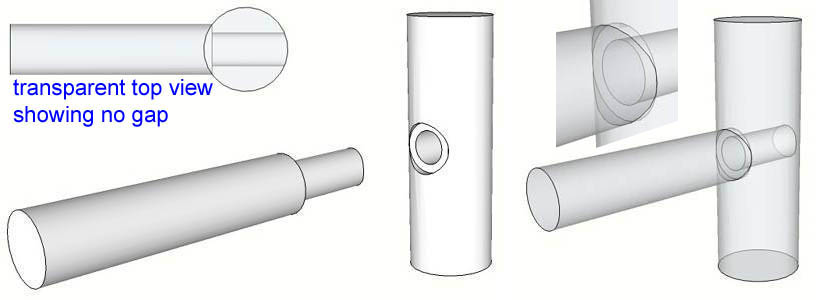

router bit --- A cutting bit used in a router. The variety of such bits is not mathematically infinite, but it's really, really large. Examples:

router burn --- synonymous with machine burn

router table --- A small construction, either purchased or shop made, that is designed to hold a router with the router housing under the table and the router bit protruding above the table. An adjustable fence, sometimes with separately adjustable infeed and outfeed sections, allows control of the depth of cut. Such a table turns a router into a light duty shaper. The table provides more solid control of the workpiece than is usually available when just putting the router directly on the workpiece itself. Examples:

routing --- using a router or hand plane to cut groves in, or modify the edges of, boards.

rub bearing --- synonymous with roller bearing

rubber mallet --- A type of mallet that is not just made of rubber, but also has a particular shape; think of a tin can sized and shaped chunk of rubber with a handle stuck in the middle of the side of the cylinder. Other mallets made of rubber with significantly different shapes are carving mallets. Used for general whacking in situations where a metal, or even a wooden, striking tool would give too strong a blow. In some cases (not in woodworking) it is used because a metal mallet or hammer might cause a spark. Examples:

rubble --- (1) Broken up pieces of masonry; sometimes used as fill inside poured concrete steps.

rubble --- (2) A masonry construction technique in which broken up and irregularly shaped pieces of masonry are used with concrete or other bonding agent to form a wall, foundation, walkway, or whatever. Compare/contrast to ashlar.

rub collar --- synonymous with roller bearing

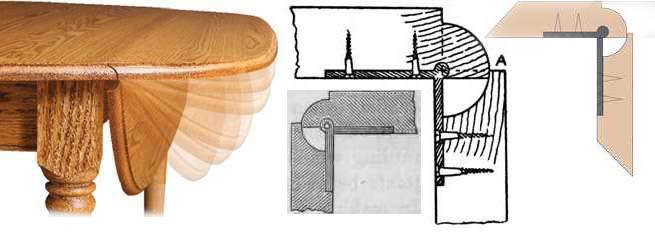

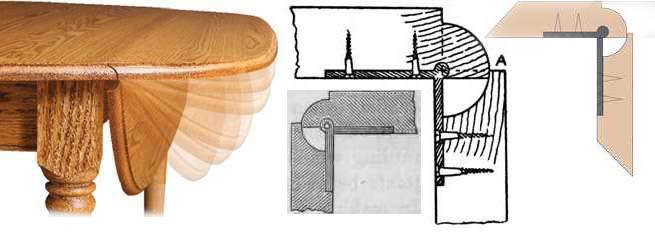

rule joint --- A joinery method used in drop leaf tables where the tabletop has a convex profile and the leaf has a concave cut. The two pieces are joined by a drop leaf hinge and the shaping of the joint allows the leaf to drop down to vertical when not in use and to be horizontal when in use. The rule joint provides a more elegant look than would be achieved by just face mounting a butt hinge underneath a butt jointed leaf. Examples:

ruler --- A (normally) one-foot long piece of wood, plastic, or metal that is marked off with one-inch and fractional-inch marking (or metric unit markings) for use in determining small distances with considerable accuracy. A 3-foot long version is called a yardstick and there are specialty rulers such as the triangular-cross-section engineer's ruler. There are images of a steel version with the term steel ruler.

run --- (1) synonymous with going

run --- (2) In framing a roof with a roof ridge, this refers to the horizontal distance from the outer edge of the top plate to the centerline of of the ridge board. Compare/contrast to rise.

runners --- Strips of wood that support a drawer and simultaneously provide a surface on which the draw slides.

running --- Sagging and curtaining of a finishing agent, usually caused by improper thinning, excessive film build or poor application techniques.

running match --- synonymous with sequence match

runout --- (1) The amount of deviation from rotational center in a router or shaper collet, lathe chuck, or other rotating center, usually measured in thousandths of an inch. Runout causes wobble in a rotating piece, which in turn can cause vibration and/or irregular cutting action, all of which are bad things.

runout --- (2) The amount of left-to-right movement that the cutting edge of a circular saw blade makes during operation. Also referred to as wobble or warp.

runs --- see running

rust --- (1)[noun] A chemical combination of iron and the oxygen that iron will suck out of water, very much including the water that occurs naturally in the air. It occurs on ferrous metals. Rust flakes off portions of the surface of such metals and over time this process can eat away all of the metal. This makes protecting structural steel (e.g. bridges) from rust very important. When steel parts in tools do not need oil for lubrication, they are often oiled anyway, as a rust prevention measure. For example, the shaft of a floor model drill press doesn't need oiling for lubrication but they always have a raw steel surface and if you don't oil them every now and then they will rust unless your woodshop is in the sahara desert.

rust --- (2)[noun] A plant disease, caused by certain fungi (called rust fungi), which is characterized by a reddish-brown discoloration of leaves and stems.

rust --- (3)[verb] To deteriorate due to the formation of rust (see noun definition above concerning metallic rust)

rustic grade --- A wood flooring grade in which the planks are allowed to exhibit a full range of natural character, and in some species, allows the occurrence of holes through the pieces of flooring. In exotic species, it generally indicates high sapwood content and filled knots. The word "rustic" is sometimes used to designate a wood figure but I see this an inappropriate use of the term.

RWL --- Random Widths and Lengths --- see short pack

for images of wood itself, go here: wood id site

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY