The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

machine bolt --- (1) A little-used term that simply designates a hex head bolt or square head bolt.

machine bolt --- (2) [little used] synonymous with machine screw.

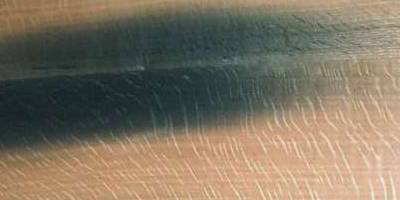

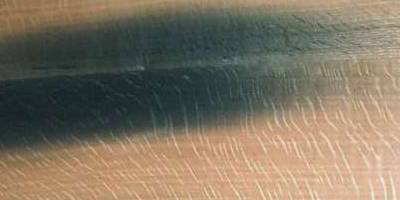

machine burn --- A darkening of wood due to overheating by a cutting edge. This can occur for two primary reasons, first that a cutting edge is dull and second that the wood and cutting edge are too long left touching in the same place. Also called "cutter burn", "knife burn", "router burn" and so forth, depending on what tool edge made the dark area.

machine nut --- A term that is rarely used because it is what most people MEAN when they say "nut", so rather than being called a machine nut, it would normally just be called a nut. It is a type of nut that can have a square or hexagonal outside and is about half as tall as it is wide. The more common names for these are based on the shape and are "hex nut", "hex head nut", "square nut", and "square head nut". There is a special-use machine nut called the jam nut which is just a thin hex-headmachine nut. Examples:

machine offset --- An abrupt change (generally small) in the width or thickness of a plank due to the plank shifting relative to a cutting edge during dressing. The most common form of this is snipe.

machine screw --- This is a VERY widely used term that is actually a misnomer but perfectly acceptable because of wide usage. Anything that someone calls a "machine screw" is 99%+ sure to be a small bolt and if it isn't a bolt, it's a screw (not a "machine" screw). See also, bolts vs screws. The name seems to have come about because in earlier days of bolts and screws, bolts were always bigger than screws, so when small versions of bolts were developed with the advent of more precise threading capabilities, they were called machine screws instead of bolts. Compare/contrast to wood screw. Example:

machine taper --- A mechanism that allows for quick changing of chucks on rotary tools such as drill presses and lathes. The taper is a hollow metal cylinder, tapered slightly so that the diameter decreases from the opening to the interior end. A corresponding chuck can be slipped into this taper and when both surfaces are clean, the rotational friction grips the chuck with sufficient force that ridges are not required to keep the chuck from slipping. A very slight covering of oil creates such a tight fit that the chuck does not fall out even when it is pointing downward in a drill press. Tapered chucks are removed in various ways; on a lathe, there is normally a hole that gives access to the rear of the chuck and a rod is inserted and tapped. Just tapping on a rapping lightly but very sharply on a chuck will often free it. Since the tool and the chuck have to have the exact same degree of taper, standards are very important and different types of tapers are not interchangeable. The most common standard is the Morse taper which comes in 8 different sizes, all with about 3 degrees of taper.

machinist center punch --- A center punch that is to be used on metal and that is, instead of being hit with a hammer, spring loaded. You push it against a metal surface and when you have exerted enough force against the internal spring, a release mechanism is tripped and the spring drives an internal bolt down against the inside of the tip, and the tip then makes the desired mark in the metal. This device is also called an "automatic center punch" and a "spring loaded center punch". Examples:

machinist's bench vise --- A hefty vise that is designed to be bolted to the top of a workbench and used in metalworking. This type of vise normally swivels around its base. I don't think you will ever see an auto repair shop that does not have one of these. Compare/contrast to woodworking bench vise. Examples:

magnetic starter --- A type of safety power on/off switch, often used on large stationary machines. When put in the on position, an electromagnet is powered and holds the contacts in the on position, but if power goes off, the electromagnetic dies and a spring opens the contacts. This prevents an automatic restart when electrical power returns.

malleable --- In general English usage, the term refers to something that is easily manipulated to cause a change in its shape. Specifically, it refers to a material that can withstand sever compressive forces by changing shape. The prototypical malleable material is gold, which can be hammered and/or rolled into very fine sheets. Compare/contrast to brittle.

mallet --- A tool somewhat like a hammer but with a large bulky head, usually made of wood, hard rubber, leather, or other non-metallic material, used primarily to drive chisels or perform other striking operations where what is needed is a softer blow than would be provided by a metal-head striking tool. Some mallets, particularly carving mallets, are made with brass heads which is a metal, but a softer metal than the steel that hammers are made from, plus the brass is usually just a cylindrical shell around a wooden core, which further softens the blow from such a mallet. There are numerous styles of mallet, but for the purpose of this glossary, I have broken them out into the following categories and have illustrated each:

- carving mallet --- several types, but all used for the same purpose

- rubber mallet --- general purpose whacker; not generally used for carving

(carving)

mandrel --- (1) A metal rod that holds revolving tool parts, such as the headstock spindle of a lathe, the arbor of a circular saw, or the spinning part of a dentist's drill.

mandrel --- (2) A metal pole, either hollow or solid, of iron or wood, designed to hold a hollow part while it is being forged or turned. The tube used by glass blowers is a mandrel. Sometimes the mandrel is tapered and the workpiece is jammed onto it for a pressure fit.

mansard roof --- A roof design with nearly vertical roof planes at the outside that tie into roof planes of less slope, or even a flat surface, up towards the top of the roof. Examples:

mantle --- An ornamental facing surrounding a fireplace or simply a shelf above a fireplace. Fancy mantles often have corbels as decoration at each side.

manufacturing defects --- Includes all defects or blemishes that are produced in manufacturing wood, such as chipped grain, loosened grain, raised grain, torn grain, skips in dressing, hit and miss (series of surfaced areas with skips between them), variation in sawing, miscut lumber, machine burn, machine gouge, and so forth.

mar --- [noun] A scratch, rub mark, dent or other mechanically introduced flaw on a surface.

mar --- [verb] To harm a surface by mechanical means (by scratching, denting, etc.)

marine borers --- Mollusks and crustaceans which attack submerged wood in salt and brackish water.

marine grade --- An APA panel rating that refers to Plywood panels manufactured with the same glueline durability requirements as other exterior grade panels but with more restrictive veneer quality and manufacturing requirements. The grade is particularly suitable for marine applications where bending is required, as in boat hulls.

market pulp --- White pulp from hardwood trees that is dried into thick blotter-like sheets and baled for shipment to a paper mill for re-pulping to make paper products.

marquetry --- A decorative craft in which patterns are formed by the insertion of pieces of wood veneer onto a substrate to create an image. All the peculiarities, grain, knots, defects, etc. are used in the overall effect of the picture and veneers of highly figured woods such as burls and spalted woods are often used to good effect in marquetry. Compare/contrast to parquetry and intarsia. Materials other than wood can be used in marquetry. There are TONS of sites on the internet that will tell you all about marquetry techniques. Here are a couple of examples. The first one is, deliberately, a beginner-level effort that looks somewhat like the results from the old "paint-by-the-numbers" kits I played with as a kid. This is a very nicely executed piece of marquetry and notice the way the wood grain has been used to advantage as part of the image. The second, again deliberately, is more elaborate and I've shown a blow up of one section.

mar resistance --- The ability of a finish to resist scratching and denting.

mason --- A worker who constructs things with masonry

Masonite --- A specific brand of hardboard and since it is a brand name, it should always be capitalized, but it is one of those brand names, like chocolate and kleenex, that have entered the English language as a generic term.

masonry --- (1) Stone, brick, concrete, ceramic blocks, and other similar building materials that are usually bonded with mortar. If laid without mortar, it is said to be dry set. The two basic types of masonry are ashlar (using material that has been given regular rectangular edges) and rubble (using irregularly shaped material)

masonry --- (2) The process of building using the items listed above, including the processes of quarrying, cutting, shaping, and jointing the materials.

masonry --- (3) A building, or part of a building, built from the items described above.

masonry drill bit --- A drill bit that either has a carbide tip or which is made entirely from an extra-tough metal (such as titanium), and which is used to drill holes in masonry. In the examples shown below, the bottom bit is listed as a masonry bit, but I don't think it would be a good one because masonry bits normally have a tip that is wider than the shank so as to provide extra clearance for the rubble that results from drilling masonry.

masonry nail A type of nail that is specifically designed to be driven into masonry. These are of hardened steel and come in several shank styles. Most definitions say that a masonry nail has a fluted shank for extra holding power in masonry, but in practice many items sold as masonry nails do NOT have fluted ridged shanks. There is a type of masonry nail (not shown in the composite pic below) that is specifically designed for holding down softer material, such as carpet tack strips to a concrete floor, that have an extra wide head. Examples:

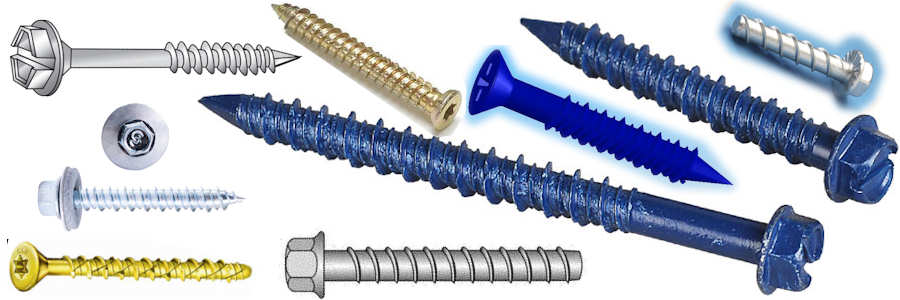

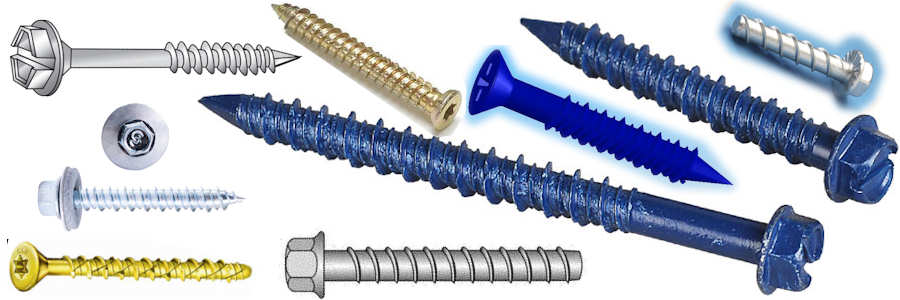

masonry screw --- Also called a "concrete screw", this is a coarse-thread screw that, unlike most screws, has a straight, rather than a tapered, shank (but they do have tapered ends). It is designed to go directly into a hole drilled in masonry with a masonry drill bit. The coarse threads are necessary to grip mansonry and the need for strength dictates that these are always made of steel. Masonry screws have various types of drive heads but the most common is a combination flat head drive slot in a hexagonal top like that of a hex head bolt. Similar-use fasteners include a lag screw with a lag screw shield and any normal bolt used as an expansion anchor bolt. Such screws often use hi lo threads. Examples:

mast --- (1) The fruit and nuts (e.g. acorns, chestnuts, berries, etc.) of trees that serve as food for wildlife.

mast --- (2) The main sail-carrying vertical pole on a ship.

mastic --- (1) A very general term for any of a number of sealing compounds. The common characteristics of mastics are that they are thick and are either extruded from a caulking gun or spread with a trowel or similar spreader. Some common uses of various mastics are sealing and waterproofing exterior joint such as window and door frames, bonding tile to a substrate, bonding roof shingles and flashing, sealing foundation walls, and sealing plumbing where it goes through exterior walls.

mastic --- (2) A resin taken from the bark of the mastic evergreen tree in the Mediterranean and used to produce varnish.

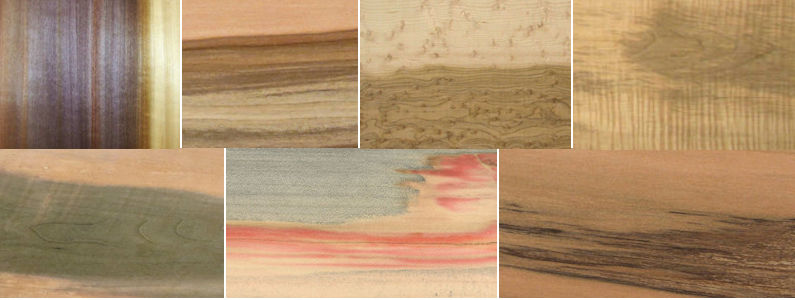

masur --- [also karelian] A particular wood figure that occurs in birch and is somewhat similar in appearance to the bird's eye figure that occurs in hard maple. It is the result of localized fiber damage caused by a beetle (Agromyzia carbonaria) and is sometimes described as a form of pith fleck. Like bird's eye maple, the logs that have it are normally rotary peeled and also like bird's eye maple, the size, shape, and density of the flecks varies considerably. Here are some examples ranging from light to heavy fleck density and also showing some of the range of fleck shape:

matched lumber --- Lumber that has been given a tongue on one edge and a groove on the other so that it is ready to be used in tongue and groove construction situations such as flooring or wall paneling.

matte --- see finish rating

mature wood --- Wood which characteristically has relatively constant cell size, well-developed structural patterns, and stable physical behavior --- also called "adult wood". Contrast to "juvenile wood". Mature wood is all of a tree except for the very center area (the "juvenile wood" just referenced).

maul --- (1) a heavy wooden hammer-like device which can be as simple as a cylinder of wood that is reduced in diameter at one end as a handle. These are used for striking a heavy carving chisel or a froe. The head of a wooden maul can be cylindrical or rectangular and they are generally quite short. Lignum vitae is a favored wood for mauls because of its weight and durability. In this sense (this definition #1), a maul is much the same as a mallet.

maul --- (2) A tool very similar to a hammer but with a very larger metal head, used for serious pounding of things such as a splitting wedge. Think of a short-handled sledgehammer.

maul --- (3) see splitting maul

maximum crushing strength --- A measure of the ability of a piece of wood to withstand loads in compression (parallel to the grain) up to the point of failure.

MBF --- see thousand board feet (when the letter "M" is used to mean 1000, it is because "M" is the Roman numeral for 1000)

MC --- [also M.C.] moisture content

MDF --- see Medium Density Fiberboard

MDO --- Medium Density Overlay

measuring compass --- synonymous with dividers

mechanical advantage --- The principle in classical mechanics whereby force and distance can be traded off against each other in a direct relationship so as to magnify one or the other. An example of a force magnification would be when a 50lb child 10 feet out on a see-saw can raise a 249lb man who is only 2 feet out on the other side of the fulcrum. The child is exerting 500 foot-pounds of force and the man is only exerting 498 foot-pounds, so the child wins even though considerably lighter than the man. An example of distance magnification would be when a 251lb man 2 feet out on a see-saw moves down 1 foot and causes a 50lb child who is 10 feet out on the other side of the see-saw to move up by 5 feet. The man and the child both go through 26 degrees of movement relative to the fulcrum of the see-saw but the man is only 2 feet out and child is 10 feet out, so the child moves 5 times as much as the man in linear motion. A seemingly different, but actually identical, application of mechanical advantage is when a pully is used to magnify force. If you have a three-wheel pully, then you can pull a rope down by 3 feet with 100lbs of force and simultaneously raise a 300lb weight up by 1 foot.

mechanical defects --- Wood flaws caused by mechanical means (as opposed to biological defects, for which see biodegraded, or by insects, for which see insect attack). The primary source of mechanical defects is drying the wood (see drying defects), but there are others.

mechanically laminated timber --- Laminated timber where the laminations are joined with mechanical fasteners. Bolts used for this purpose are called "stitch bolts". Compare/contrast to glulam.

medallion --- A decorative design of parquet flooring assembled in the center of a room or in a high-visibility area. Many come factory-made, but they can be custom-made as well.

medium density fiberboard --- [MDF] A man made material used as an alternative to wood. Wood waste is steamed before passing through a refiner to reduce it to a uniform fibrous form and then a waterproof resin is mixed in with the fiber and the whole thing is compressed under high pressure, with heat, to form panels that have uniform density and a very smooth natural finish. It is very stable and durable and is often used for underlay for counter tops and other items that are to be covered with a laminate. The density range for MDF is quite wide; 30 to 50 pounds per cubic foot. When MDF is used in cabinet construction, it is often joined using confirmat screws.

medium density overlay --- Exterior grade plywood finished with an opaque resin-treated fiber overlay to provide a smooth surface ideal as a paint base. Recommended for siding and other outdoor applications, and for exterior signs and displays, exterior furniture, etc.

medium grained --- A somewhat loose term indicating wood that has modestly spaced growth rings and/or a medium texture. Examples of such wood include walnut and mahogany. Compare/contrast to fine grained and coarse grained.

medium knot --- A knot no more than between 3/4" and 1 1/2" in diameter. This definition is often seen, but I'm not aware of any governing body that has, or even can, dictate this definition as absolute. See knot sizes for comparison with other knot size "definitions".

medium textured --- Wood that has a moderately smooth surface (which implies that it does NOT have large open pores. Compare/contrast to fine textured and coarse textured.

medullary rays --- Strips of parenchyma cells extending radially (that is, going horizontally outward from the pith to the cambium) within a tree and varying in height from a few cells in some species to four or more inches in oak. Although technically "Medullary rays" are only those that are connected to the pith, the generally useage of the term encompasses ALL rays. The rays store food and transport it horizontally in the tree. The rays in softwood trees are smaller than those in hardwood trees and more often contain tracheids. In softwoods, the rays may make up 5% to 10% of the weight and in hardwoods they may make up from 5% to 30% of the weight. All trees contain such rays, but in most woods they are unobtrusive. However, rays can cause drastic alterations in the structural properties of the wood, such as is the case in white oak, and on quartersawn cuts of such species with large rays, the there is a conspicuous figure, referred to as ray flakes (or flecks). See ray flake for illustrations. Here's an example of extremely strong rays in lacewood. The rays are the almost horizontal lines and as you can see, they are so strong that if you didn't know about rays, you would likely assume that the obvious lines were the growth rings. For more pics of rays, see rays.

MEK --- Methyl Ethyl Ketone

membrane --- A thin, pliable, sheet of tissue (in plants) or other material (in more general use).

metal stain --- A dark gray or black stain that can be caused in some woods when they are moist and touching ferrous metal for some time (I'm not clear on how long this takes). Metal stain doesn't make the wood any weaker, but it sure does make it ugly. Here's an example of metal stain in a pair of otherwise very attractive white oak planks:

methyl ethyl ketone --- [MEK] A low boiling-point, highly volatile flammable solvent with extremely good solubility for most vinyls, urethanes and other coatings.

metric --- having to do with the system of measurement that uses grams instead of pounds and liters instead of gallons and so forth. Easier to use than the pound/gallon system (the socalled "English" system) because everything in a measurement type is a factor of units of 10 from everything else in that type. So instead of having inches and feet and yards and miles, distance is measured in meters, period. Long distances are discussed in 1000's of meters (kilometers) short distances are discussed in micrometers (1 millionth of a meter), but it's all meters. Although most woodworking in the USA is done using the English system, there are some tools that use metric dimensions, so a fully equipped shop would have to have some tools (e.g. Allen wrenches) in both metric and English sizes. Compare/contrast to the English system.

micro bevel --- Refers to a small (less than 1mm) 45 degree bevel used on the edges of prefinished wood flooring products. Because prefinished wood floors cannot be sanded for uniformity when installed, small variances in face height of each plank can cause things (such as your socks) to "snag" on a raised edge. The micro bevel helps avoid such snags.

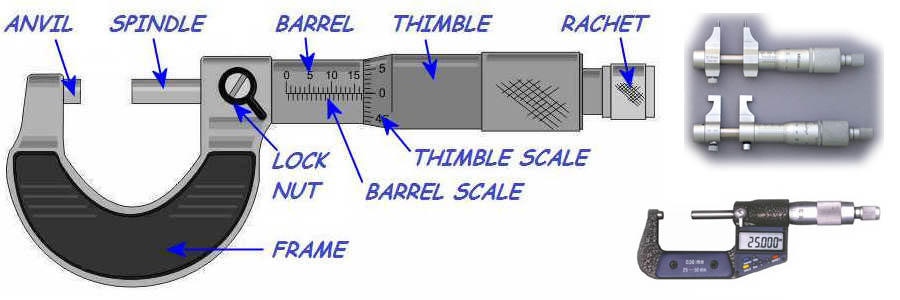

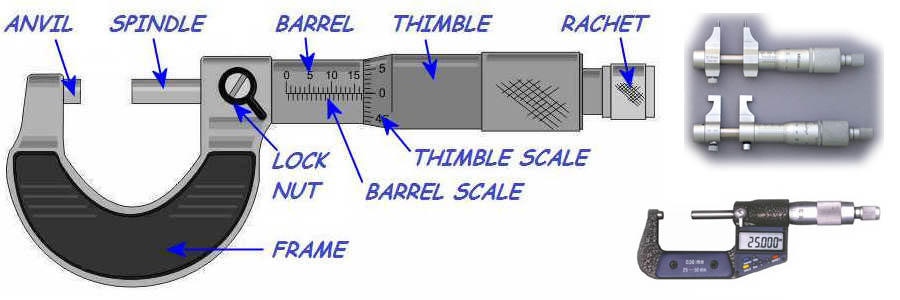

micrometer --- A precision measurement tool, used more in metal working than in woodworking. The varieties that are likely to be useful (and affordable) in the average hobby shop are precise down to .001 inches but can be interpolated down to, and are nominally accurate down to, +/- .0001 inch. Dirt, temerature variations, and operator error can cause erroneous readings down at the .0001 inch range. Unlike calipers, a similar device which relies directly on linear movement, these devices work by changing relatively large rotational movement around a precisely made screw into relatively small linear movement which is then read on a scale and this mechanism allows for much better accuracy than on calipers. The common parts are labeled on the pic below. Rather than a barrel scale and a thimble scale, there are versions today that have a digital readout and there are versions where the anvil and spindle are shaped differently than the "standard" version. In all versions, the thimble is adjusted to a very close reading and then the ratchet is adjusted to get it as precise as possible. Examples:

micron --- A micro-meter; one millionth of a meter (.000001 meters). It takes 25,400 microns to make one inch. This is not a term that comes up very often in woodworking.

mil --- One thousandth of an inch.

mildew --- Although not technically identical, mold and mildew are generic terms that describe a variety of microorganisms. In strictest terms, they are produced by fungi, but other microorganisms such as algae, yeasts, and bacteria cause similar growths that are commonly designated as mold or mildew. They grow in the presence of warmth and moisture and become a film of organic material that is often slimy, sometimes downy, but not dangerous. On hard surfaces such as bathroom tile (a common place to find them) they can be easily cleaned up with Clorox, but their presence probably indicates that you need better ventilation. They grow readily on moist fallen logs and will sometimes show up on various types of roofing or siding.

mildewcide --- A chemical that inhibits the growth of mildew by killing the fungii that cause it.

milk paint --- A paint made with milk solids, chemically akin to casein glue, often the original finish on antique furniture.

mill --- add definition

mill chipper --- add definition Compare/contrast to hammer mill, tub grinder, and whole tree chipper.

millwork --- Objects manufactured at a lumber mill or woodworking plant for use in the building construction industry. This most particularly includes doors and windows and their trim, decorative interior trim, stairway components, fireplace mantels, and so forth. It does not include flooring.

mineral oil --- A refined petroleum product with a fairly low volatility, suitable for use as a wood finishing agent. There is a particular formulation of mineral oil marketed as "food grade" mineral oil that is generally the refresher of choice for butcher blocks that have dried out (as they all do, since the knife cuts expose more wood to the air and thus to evaporation of the wood's moisture). It also makes the grain of wood pop.

mineral spirits --- A refined petroleum product with fairly high volatility suitable for some thinning operations. Paint thinner contains mineral spirits (and other chemicals). Mineral spirits are often used to moisten planks for photography when they are to be sold on the internet or represented in catalogs because mineral spirits make the grain pop and enhance the color in a way similar to what is likely to happen to the wood when a permanent finishing agent is applied, and then the mineral spirits evaporate off the plank although I'm not clear on how long that takes. You can get the same results for pictures by spraying wood with a light coat of water, but there are some woods, especially dye woods that will suffer water stain so mineral spirits are a better idea.

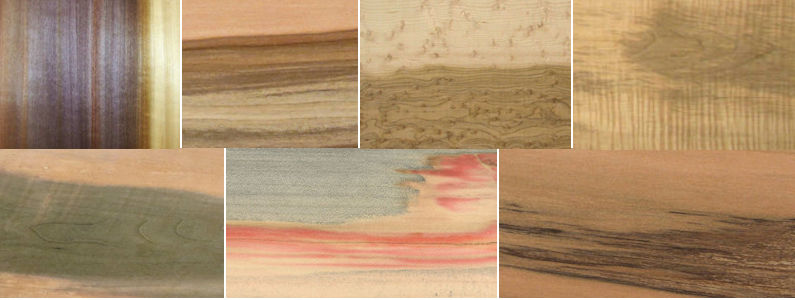

mineral stain --- An olive to greenish-black or brown and sometimes even purple discoloration in wood. It is a common, and completely understandable, misunderstanding that the name is to be taken literally --- that is, that the cause of "mineral stain" is minerals brought up from the soil through the sap. This is NOT usually correct and the actual causes are unknown, although SOMETIMES it actually IS minerals brought up through the sap. It occurs in some hardwoods and the stain occurs parallel to the pores, not cross-grain as can occur in fungal stains. It is particularly common in hard maple and yellow poplar, but also occurs in other species such as anigre, hickory, basswood, and others. In hard maple, it is commonly a gray stain but in yellow poplar it can take on many colors, sometimes all in one plank, leading to some spectacularly colored wood which is then called rainbow poplar. Below is a pic of mineral stain in various woods. To see more discussion and more pics of mineral-stained wood, click here: mineral stain pics.

mineral streaks --- synonymous with mineral stain

mirror screw --- A screw or a bolt that has a threaded hole in the middle of its head (in addition to the drive slot) so that another, smaller screw with a large decorative head can be screwed into the top of the mirror screw for use in a mirror (or elsewhere that "elegance" is desired) so that what shows doesn't look at all like a screw head, it looks like a decorative circle or dome (these heads are typically brass or are chrome-plated). Examples:

miscible --- Capable of mixing or blending uniformly. Technically it is used to refer to all fluids including gasses, but it is most commonly used to refer to fluids. Antonym is immiscible.

miter --- (1)[verb] To make a diagonal cut at specific angle (often 45 degrees, but it could be 30 degrees or any other angle), with the purpose of fitting two workpieces (e.g. two sides of a picture frame) together.

miter --- (2)[noun] A cut made as described in (1) above. See miter cut for an illustration.

miter --- (3)[noun] synonymous with miter joint

related terms:

miter and spline joint --- see splined miter joint

miter box --- An apparatus to guide a saw (usually a backsaw) to make miter joints. The cut produced can be at an angle to the long dimension of a board, or to the face. Examples:

miter box saw --- synonymous with back saw

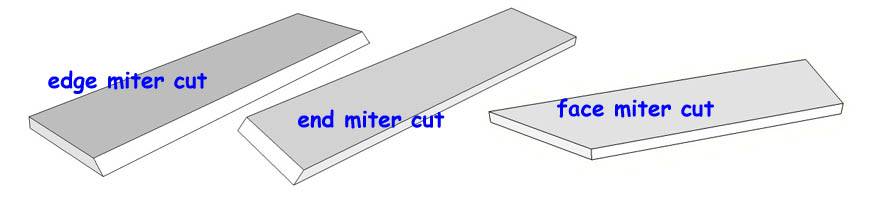

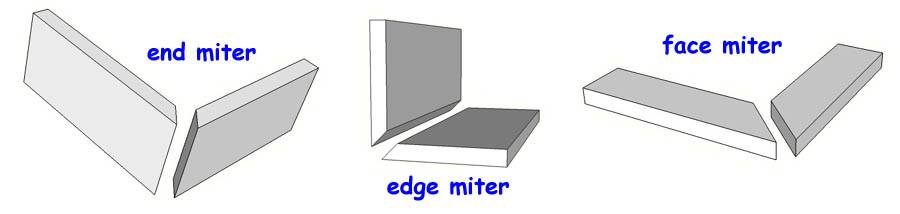

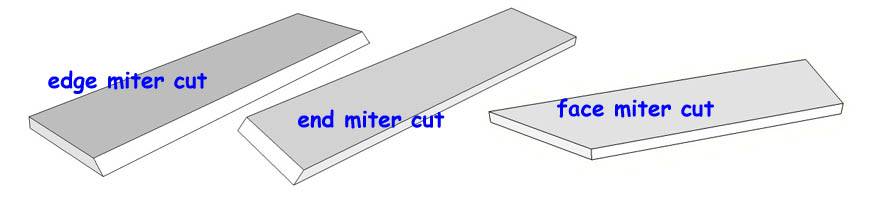

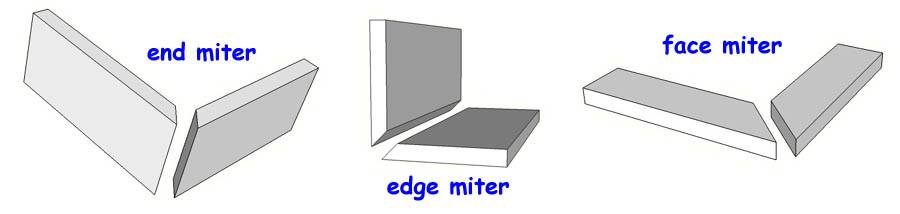

miter cut --- A diagonal cut at specific angle (often 45 degrees, but it could be 30 degrees or any other angle), across the end of, or along the edge of, or across the face of, a plank. When the cut is at an angle to both the edge and the face, it is a compound miter cut. Examples:

mitered --- Cut at an angle. See also, miter joint.

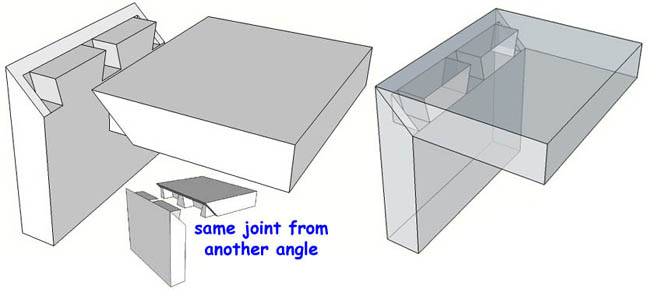

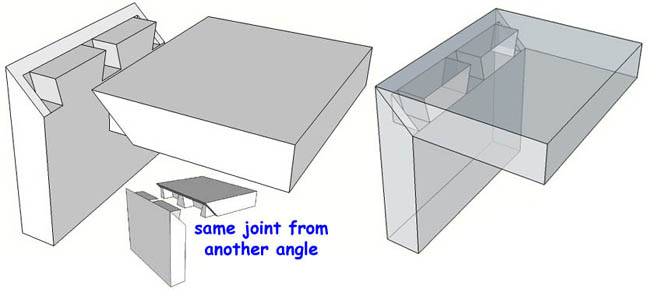

mitered blind dovetail --- A dovetail joint that has the pins and tails hidden inside a miter joint. This is a really nifty looking joint, but I have to believe that the only people who actually make it have WAY too much spare time on their hands. Example:

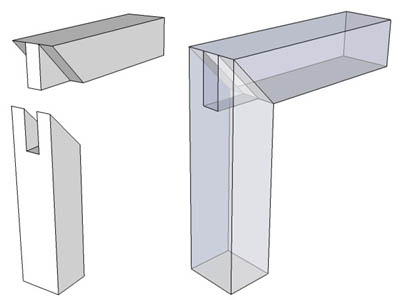

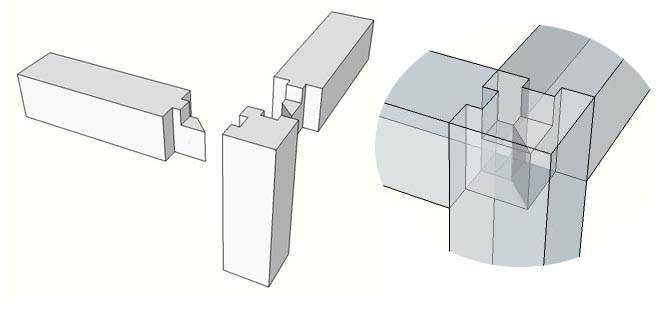

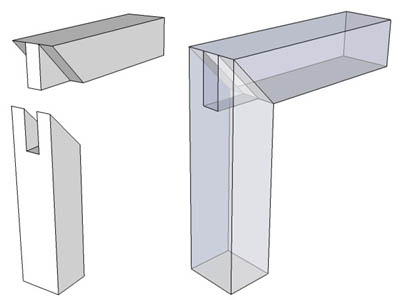

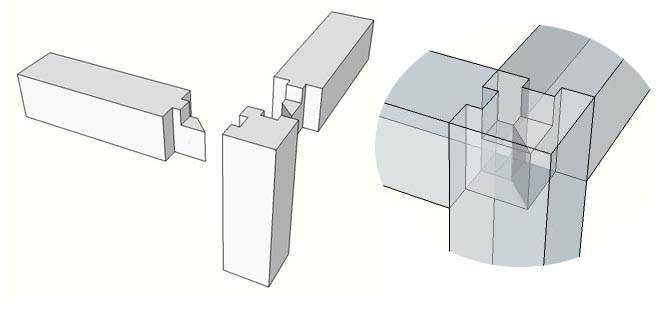

mitered bridle joint --- A joint like a standard through bridlejoint except that the prong and groove are mitered rather than being square. Examples:

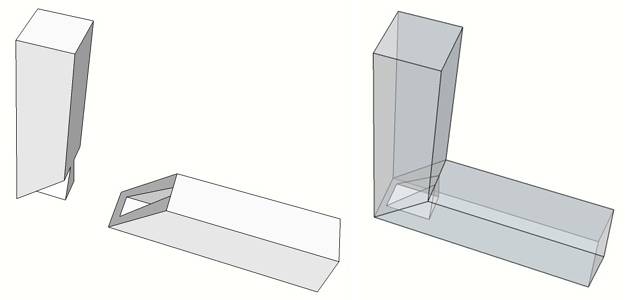

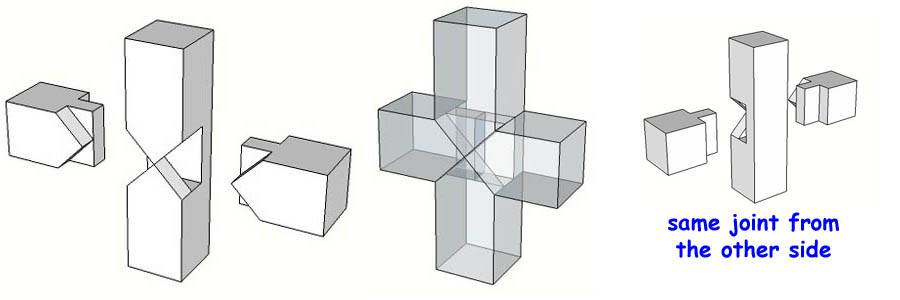

mitered corner dovetail joint --- A joint used for joining the ends of two roughly square cross sections pieces by putting a single dovetail in one and the corresponding mortise in the other. Best described by illustration, so here you go:

mitered edge rabbet --- see mitered rabbet

mitered end rabbet --- see mitered rabbet

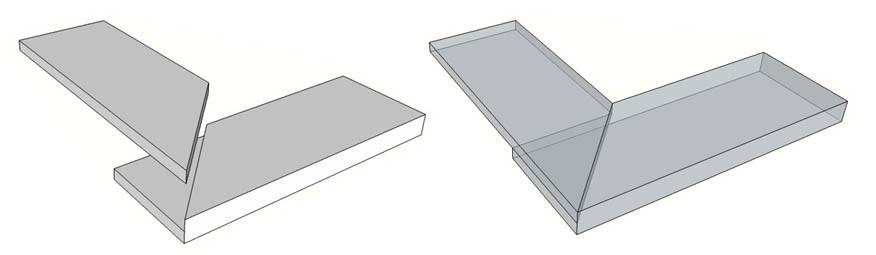

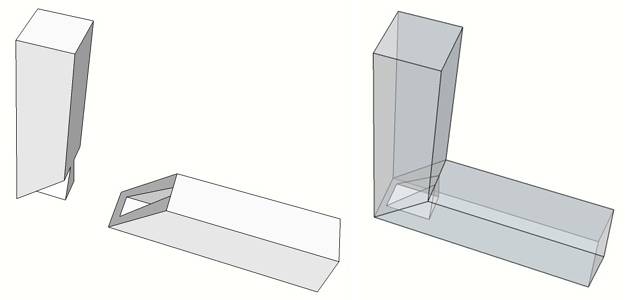

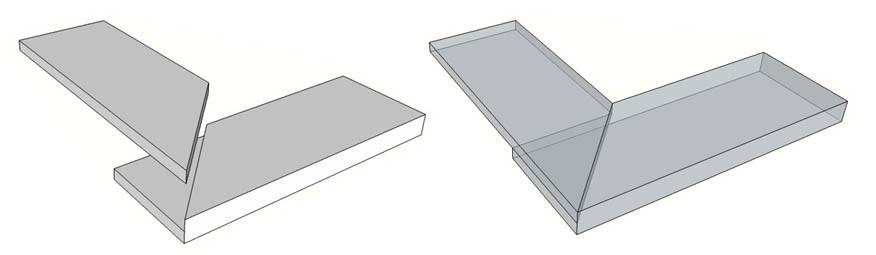

mitered full lap --- A type of corner full lap joint where the two mating pieces have their extending parts cut at an angle (mitered). Examples:

mitered half lap --- A type of corner half lap joint where the two mating pieces have their extending parts cut at an angle (mitered). Examples:

mitered joint --- A joint that includes a miter cut. (see miter joint.

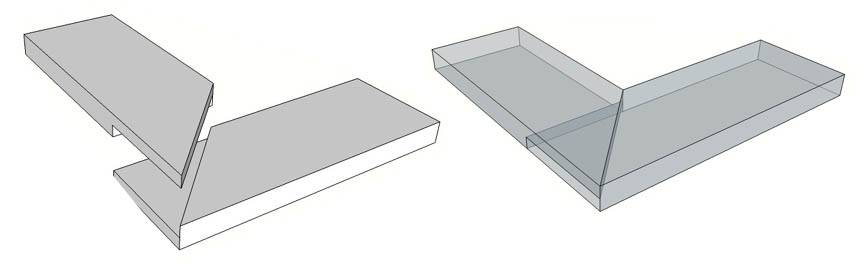

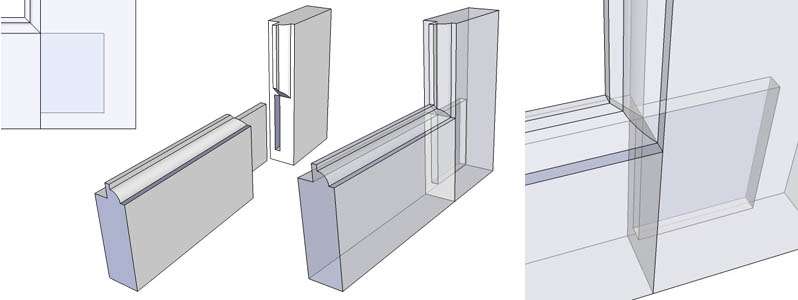

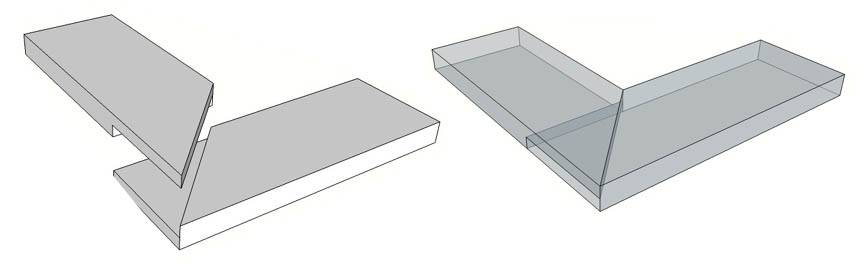

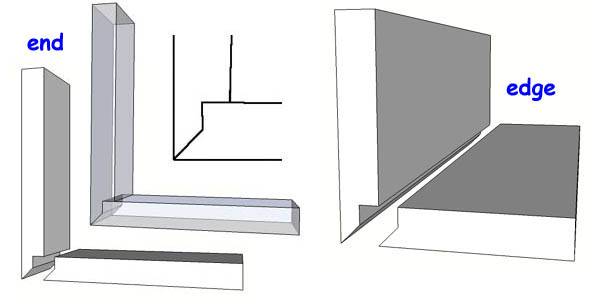

mitered rabbet --- This is a cross between a standard miter joint and a standard rabbet joint that makes it about half of each. By using the square faces of the rabbet, the joint has more resistance to slippage of the pieces relative to each other than does a miter joint, but by using the miter joint at the outer edge, the joint maintains the somewhat more elegant characteristic of having the joint line right at the corner rather than off of the corner as is the case in a rabbet joint. If the joint is at the ends of two planks, it is called a mitered end rabbet and if it is along the edges of two planks it is called a mitered edge rabbet. Examples of both:

mitered shoulder mortise and tenon --- There are two distinct joints that are both given this name:

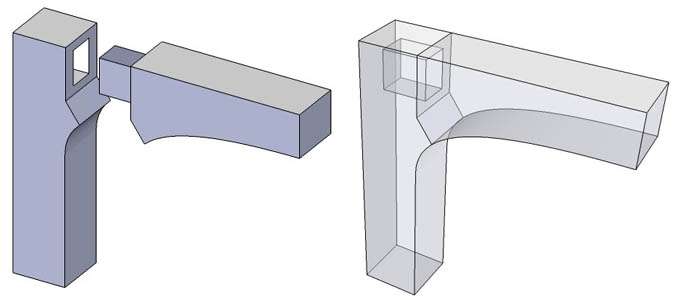

type 1 --- This is a joint that might be used on the back of a chair or on a fancy-shaped mirror frame. It is a common blind mortise and tenon joint (although it COULD be done as a through joint, and it could be haunched) but it is put into pieces that are not rectangular in shape, as shown in the illustrations below. The area below the tenon (the shoulder) is mitered as it moves away from the tenon.

type 2 --- This is a significant variation on a standard mortise and tenon and accommodates a pair of rails coming into a common leg, with each rail having a standard tenon but rather than have a vertical shoulder next to the tenon, the shoulder on one side is mitered, as shown in the drawing.

Examples of type 1:

Examples of type 2:

mitered sticking mortise and tenon --- see mortise and tenon with mitered sticking

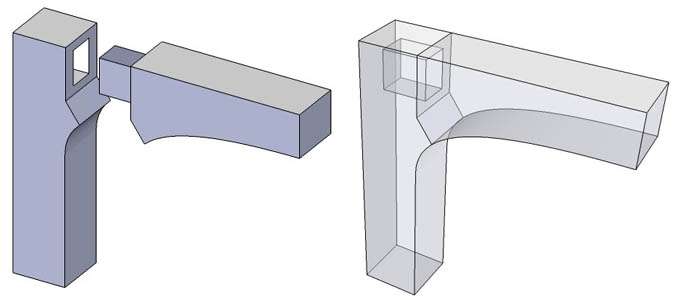

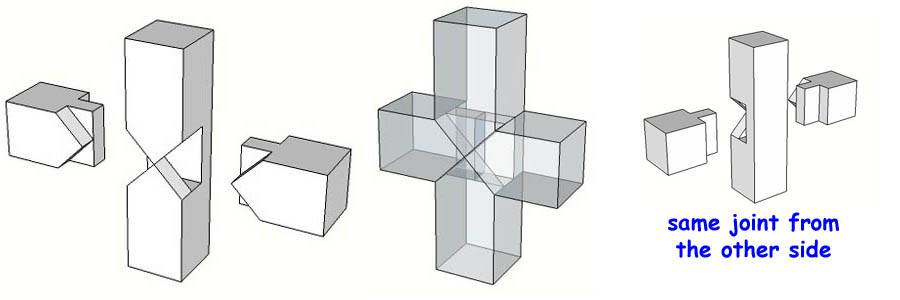

mitered tenon --- This is a standard blind mortise and tenon joint but with a twist, which is that the piece with the mortise receives tenons from two directions (actually it could even be 3 or 4) and the tenons have to be mitered on the ends so that they will go into the joint as far as possible for maximum strength. The joint can be haunched or not, as you please. A variant on this joint, but one that does not require a miter, is the notched mortise and tenon joint. Examples:

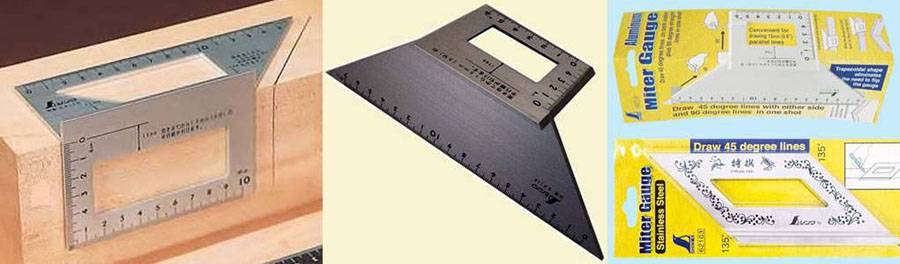

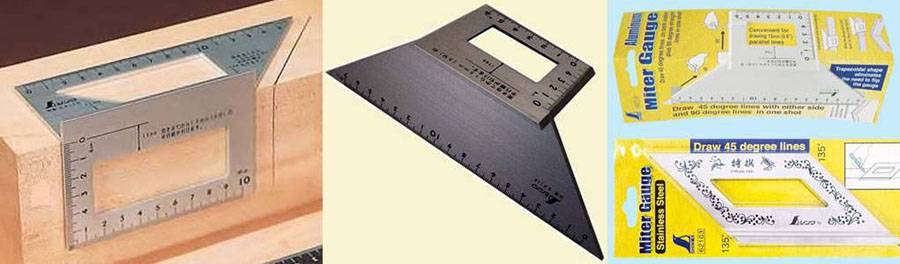

miter gauge --- (1) A tool that slides in a slot on a table saw, router table, bandsaw, etc. and which can be adjusted to different angles so as to slide the stock past the blade to achieve an angled cut.

miter gauge --- (2) A piece of angled metal or hard plastic, 2D or 3D, that accurately lays out where to mark wood for one or more angles for miter cuts.

Examples of definition (1):

Examples of definition (2):

miter joint --- A joint between two pieces of wood where the edges of each are cut at an angle (usually each at 45 degrees but it doesn't have to be that). The primary purpose of miter joints is to hide end grain. There are more different types of miter joints than you can shake a stick at. Here are a few of the most common:

miter trimmer --- A hand operated, lever based tool that uses a razor sharp angled edge to slice off the end of piece of wood that is to be used in a miter joint. The point of the trimmer is to give a smoother edge than even the best circular saw blade so that the pieces in the miter joint will mate up perfectly. An alternative to the miter trimmer is the shooting board. The miter trimmer is best explained by showing an illustration, so here are examples:

MMBF --- A million board feet ("M" is the Roman numeral for 1000, and "MM" stands for 1,000,000 BF, although it does NOT equal 1,000,000 as a Roman numeral, where it just mean 2,000. See also thousand board feet.

mockup --- A temporary construction made from scrap materials, or inexpensive materials, in order to test a design.

model code --- In terms of woodworking, this refers to a building code developed by a regional federation of building officials. These are continually reviewed and updated by committees of building officials. Model codes in the United States are the Uniform Building Code (UBC), published by the International Conference of Building Officials; the Standard Building Code (SBC), published by the Southern Building Code Congress International; and the National Building Code (NBC), published by the Building Officials and Code Administrators International (BOCA). Members of these three code organizations make up the National Evaluation Service. Building construction in the USA has to be in accordance with the local model code.

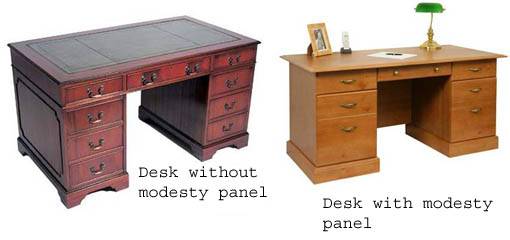

modesty board --- synonymous with modesty panel

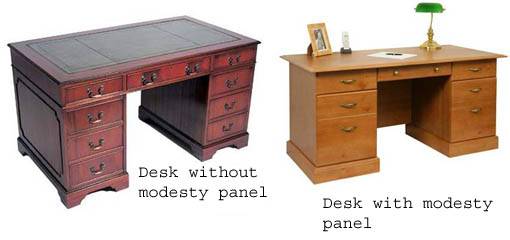

modesty panel --- A deep rail fixed between the two end frames of a desk. Its purpose was to conceal the legs of a seated person. The term was also used in older times for a panel (sometimes called a modesty board) that ran up a flight of stairs inside the stair rails, for the same purpose.

modified Wood --- Wood processed by chemical treatment, compression, and/or other means, with or without heat, to impart properties quite different from those of the original wood. Usually this is to improve resistance to rot.

moisture barrier --- Sheets of various kinds of material, mostly plastic or rubber, that are placed to block the passage of water or water vapor. Frequently used as underlayment below roof shingles. See also vapor barrier.

moisture content --- The weight of the water within a piece of lumber measured as a percentage of the weight of the oven dried weight of the wood. That is, the wood is weighed with the moisture, then completely dried out and weighed again and the moisture content is taken as (wet weight - dry weight) / dry weight, and expressed as a percentage (that ratio, multiplied by 100). To restate this in another way for clarity, it is the weight of the water in the wood divided by the weight of the wood without any water. This will NOT be intuitive to scientists (other than wood scientists) and engineers, who will think that water percentage should be taken as water weight divided by TOTAL weight; in wood science, that method is called "wet basis". The difference between the two methods is non-trivial. For example, red pine can have 2 parts water to 1 part wood when freshly cut, so it will have an oven-dry-basis moisture content of 200% but a wet-basis moisture content of 66.7%. Oven dry basis is used in wood science because one wants to always use the dry wood as the basis for all calculations.

Typical moisture content for kiln dried construction lumber is 15% (the requirement is that it be less than 19%). Wood absorbs or gives off moisture depending on the ambient moisture in the air. The percentage of wood that is not moisture is referred to as "dry solids," so dried construction lumber at 15% MC would be 85% dry solids. Product standards for lumber manufactured in the United States are developed under the jurisdiction of the U.S. Department of Commerce and administered by the American Lumber Standards Committee (ALSC). Members of the ALSC are representatives of various softwood lumber trade associations. As specified in the ALSC American Softwood Lumber Standard, softwood lumber is sold as "dry" if it has a moisture content of 19% or less. Most hardwoods manufactured in the United States are produced to standards developed by the National Hardwood Lumber Association. No single moisture content, however, is specified for hardwoods because their uses are more diverse and specialized. The moisture content must be specified by the buyer and agreed to by the seller; a 10% moisture content specification is common.

moisture gradient --- A progressive change (whether increase or decrease) in moisture content between the core and the surface of a piece of wood. One goal of proper drying is to have a very low moisture gradient.

moisture meter --- An electronic instrument for determining the moisture content of wood. There are two types of meter; one type measures the electrical resistance of the wood, the other measures the dielectric property of the wood.

moisture resistance --- The ability of a finishing agent to resist swelling, blistering, other damage caused by moisture.

mold --- (1) A wooden box or frame, also sometimes called a "form", into which concrete is poured so that it will hold a desired shape (such as a door step or foundation wall) while drying.

mold --- (2) Although not technically identical, mold and mildew are generic terms that describe a variety of microorganisms. In strictest terms, they are produced by fungi, but other microorganisms such as algae, yeasts, and bacteria cause similar growths that are commonly designated as mold or mildew. They grow in the presence of warmth and moisture and become a film of organic material that is often slimy, sometimes downy, but usually not dangerous. On hard surfaces such as bathroom tile (a common place to find them) they can be easily cleaned up with Clorox, but their presence probably indicates that you need better ventilation. They grow readily on moist fallen logs and will sometimes show up on various types of roofing or siding.

molding --- [also moulding] A term with numerous meanings, but as regards woodworking, it means a decorative strip used for ornamentation or finishing (such as to elegantly hide a joint), or a decorative recessed or relieved surface on an edge. There are a tremendous variety of sizes and shapes of molding, and you can undoubtedly find a dozen or more at your local hardware store. GIVE MORE INFORMATION, including some types ("crown", etc.)

molly bolt --- A clever device for fastening stuff to walls. It consist of a cylinder of metallic strips with full hollow cylinders at each end through which a small bolt is run and a head with a pair of spike flanges. You drill a hole in a wall, insert a properly sized molly bolt, tighten the bolt head which causes the metal strips to bend and press up against the inside of the wall, thus holding the whole thing in place. The spiked flanges on the head keep the head from spinning as you tighten the bolt. You then remove the bolt, put the thing to be mounted up against the molly bolt head and reinsert the bolt through the object, tighten it back down, and voila! There are versions that have a sharply tapered plastic cone on the end so that they can be driven directly into drywall without the need for first drilling a hole. Examples:

mop board --- synonymous with baseboard

Morse taper --- The standard for the machine taper on the shanks of drill chucks, drill bits and lathe centers. There are 8 different sizes of Morse tapers, designated by numbers; #1, at about 2.3" in length is the smallest and #7, at over 11 1/2" in length, is the largest. A #3 Morse taper is common for drill chucks. The taper angle on Morse tapers differs slightly among the sizes but all are just under 3 degrees.

mortar --- A thick adhesive paste, somewhat similar to concrete formed by mixture of cement, water, sand, and limestone; used to bind construction blocks (e.g. stone, brick, cinder blocks) together and fill the gaps between them.

mortise --- (1) A shallow cutout in the surface of wood for the purpose of mounting something (such as a hinge) so that it sits flush with the surface of the wood.

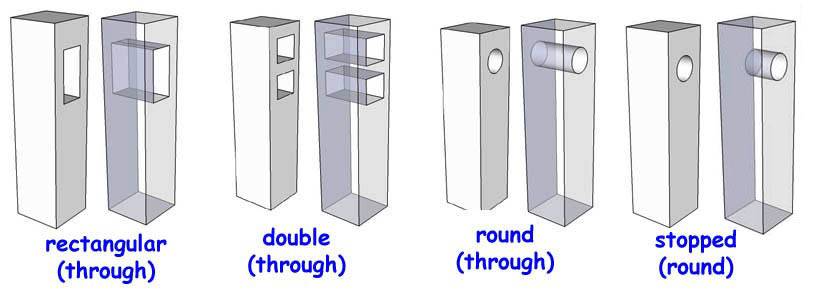

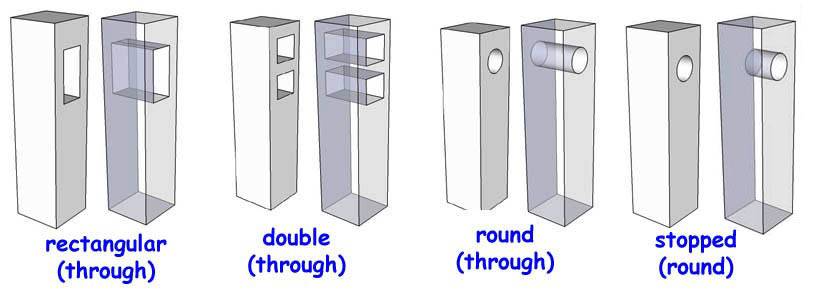

mortise --- (2) A rectangular recess into a piece of wood for the insertion of a tenon to form a mortise and tenon joint. The term is also used in a more general sense for any recess that might take some projecting piece similar to a tenon, even if it is not strictly a mortise and tenon joint. The mortise may go all the way through the piece it is in or it may stop short of the face opposite the entry point. Examples:

mortise and tenon --- A wood-jointing technique in which the end of one piece is reduced to create a projecting section (the tenon) and a section of the other piece is hollowed out (creating the mortise) to hold the projecting piece. The cross section of the tenon can be square, rectangular, circular, or even oval and when square or rectangular the edges may or may not be smoothed over. There are a HUGE number of variations on this basic technique. When the mortise is cut all the way through the receiving piece, it is called a through joint and if the mortise is not cut all the way through, it is called a stopped joint or stubbed joint (or blind joint) and the tenon is called a stub tenon. In cases where there might be considerable twisting force, an additional piece, called a haunch is added to the tenon. If there are two tenons (and two mortises) then it is called a "twin" mortise and tenon. For illustrations, see the various types shown in this glossary:

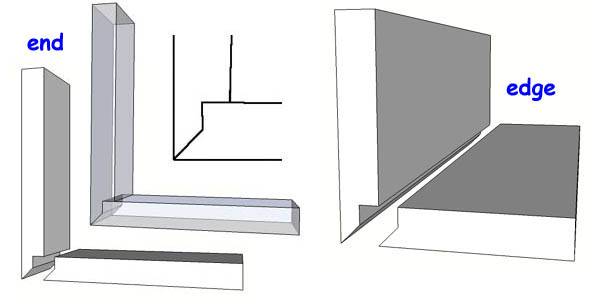

mortise and tenon with mitered sticking --- Some rail and stile planks come with sticking already molded onto the edge as part of the plank. This complicates the offset shoulder mortise and tenon joint that is often used to mate them. The sticking has to be either coped or mitered. This joint is the mitered version and it is best described by a drawing, so here you go:

mortise chisel --- A square cross section, thick bodied joinery chisel, used in cleaning out mortises.

mortised hinge --- Any hinge that has both the door leaf and the frame leaf sitting in mortises. If only one leaf (and it would usually be the door leaf) is sitting in a mortise and the other is not, this would be called a "single mortise hinge". The purpose of using mortises is so that the object being hinged can fully close; that is, some hinge mounting positions are such that if one or both leaves are not mortised, then the thickness of the leaf/leaves would keep the door (or lid or whatever) from fully closing. Compare/contrast to single mortise hinge and surface mounted hinge. See hinge mounting positions and styles for an illustration.

mosaic parquet --- A parquet floor made up of small solid pieces of wood (slats or blocks) assembled in units that may consist of individual squares, units with slats arranged in single or double herringbone design, or units or squares bordered with slats of the same or contrasting species.

mottle --- Sometimes, wavy grain in a wood combines with spiral, interlocked grain to produce a wrinkled, blotchy, but usually attractive, figure known as mottle, which would be called "curly" if the curl lines were not so broken up and sometimes containing sharp edges. If the mottled figure is scattered randomly it is technically called "broken mottle" (that is, the terms "mottle" and "broken mottle" are synonyms) but I have never seen the term "broken mottle" used. Perhaps vendors think it carries a negative connotation (hey, who wants to buy something that is broken?), but in any event, the plain "mottle" seem always to be used. If it appears as a fairly regular checkerboard pattern it is called block mottle, and a block mottle that is very regular and/or has very sharp edges, it is called razor mottle. If the block mottle has a particular kind of regularity and does not have extremely sharp edge, it might be called basket weave for the obvious reason. Anigre, makore, and sapele frequently exhibit all kinds of mottle figure, and it also occurs in mahogany, koa, bubinga, African satinwood and some other species. The various "mottle" terms are, like many terms regarding wood figure, used very loosely and should not be trusted sight unseen. Mottle figure that has very small sections, quite irregularly spaced and with sharp edges, is called bee's wing. Below is a pic of mottled anigre. To see more pics of mottled wood, click here: mottled pics.

moulding --- synonymous with molding

mountain grade --- synonymous with rustic grade

movement --- see movement in service

movement in service --- Wood is a porous, fibrous, material and when the air around it is very humid, it absorbs moisture from the air, and when the air around it dries, some of the moisture in the wood evaporates back out into the air around it. When the wood absorbs moisture, it expands slightly and when moisture leaves the wood, the wood contracts slightly. Different woods absorb and retain moisture to different extents and so they "move" (expand and shrink) by different amounts. Also, wood changes size across the grain proportionally more than it does along the grain (and it's actually a little more complicated than that) so even wood cut from the same plank will move differently based on orientation. When wood is just sitting there in the form of a plank, that isn't necessarily a problem, but when different pieces of wood are joined together with adhesives or fasteners (that is, when it is "put into service") the movement is the so-called "movement in service" and it can cause stress, even severe stress, at points in the wood and this in turn can lead to splits and cracks in the wood. Movement in service is inherent in the nature of wood; it cannot be avoided and thus sometimes has to be accommodated. The degree to which movement in service is a problem varies greatly among wood species and how an object is constructed from wood. Composite materials do not suffer this problem, or suffer it to a much lesser degree than pure wood, which is one of their advantages.

The reason door panels are done in a floating construction technique (see rail and stile construction) is because in many woods the movement in service is so large that a solid door would warp and/or crack due to it but the floating construction technique, wherein the panels are not actually attached to the rest of the door but instead "float" inside the rails and stiles, allows doors made of such woods to suffer large changes in atmospheric moisture without adverse effects.

My bowl site has a more extensive writeup about the effects of movement in service on small craft projects (such as my bowls) that use different woods glued next to each other. Different movements in service can cause serious problems in such constructs, and that is illustrated vividly on the bowl site with photographs. give URL.

The USDA has a publication called "Tropical Timbers of the World, Handbook No. 607" which lists the following for wood movement amounts:

- under 3.0% small

- 3.0 to 4.5% medium

- over 4.5% large

MT --- Morse Taper

mucilage --- As regards woodworking, this is a a liquid adhesive with low bonding strength.

mud sill --- synonymous with sill plate (reference definition #1 of sill plate)

mulch --- Any conglomeration of organic material used to cover the bottom of plants to control weed growth, retain moisture, and protect from soil erosion. Tree bark is often used for mulch, as are straw and leaves. Redwood chips are a particularly popular form of mulch because of their decay resistance.

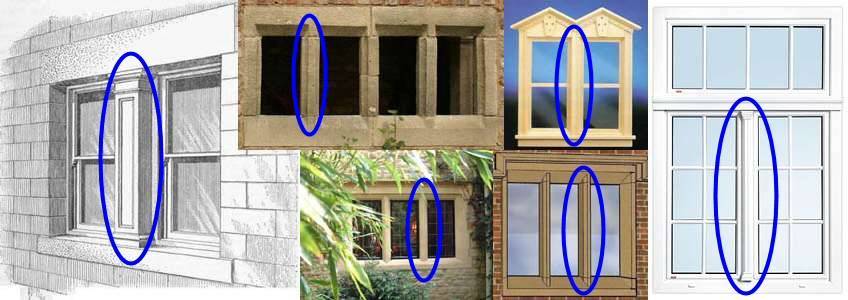

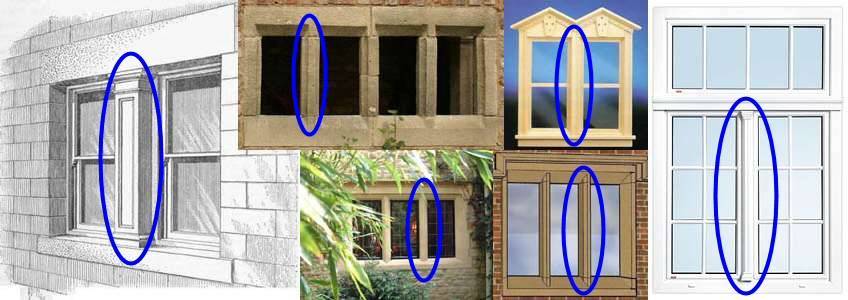

mullion --- An apparently all-encompassing term referring to any vertical member in the area of windows and doors; some definitions include horizontal members. Some reports say it is a structural member, some say it is a non-structural member. Some say it divides panes within a window, some say it is a dividing member between series of windows or doors and that pane dividers are not mullions. Pretty much all say it can be either masonry or wood. Because the preponderance of definitions favor the term as a structural member between windows that's how I present it in these examples:

multijaw chuck --- A lathe chuck with more than 4 jaws.

multispur bit --- synonymous with sawtooth drill bit

multi-tip scraper --- A lathe tool that has a removable tip that can be easily replaced when dull and/or with differently shaped tips for different uses. The tips are typically high speed steel or even carbide. Numerous manufacturers make various versions of these. Examples:

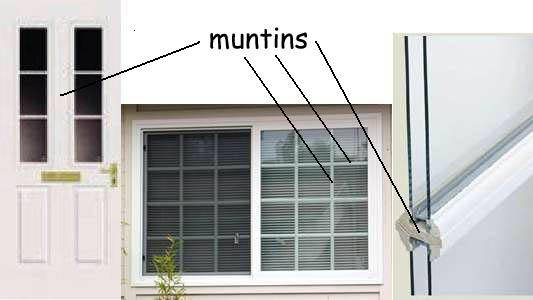

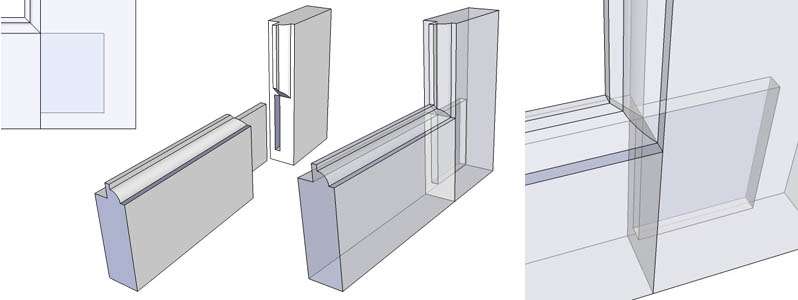

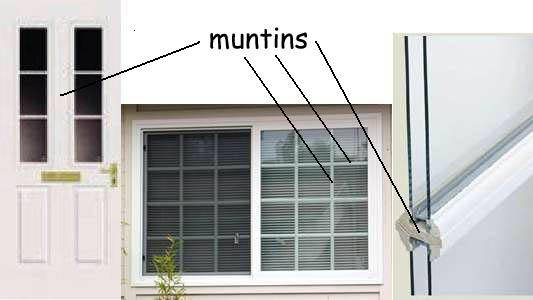

muntin --- A term used to describe almost any small strip of wood used for various purposes in windows, doors, cabinet doors, and cabinet drawers. Some definitions say it is a horizontal member but more say it is a vertical member (especially with doors). Some say it separates window panes along their edges, some say it separates pane faces in double windows. Some used it to describe a strip put across the

bottom of a wide or deep drawer to support the bottom. Some say it is a vertical drawer divider inside large drawers. Some use it to describe a horizontal strip of wood put behind a large panel in a raised panel door, as a support. Some say it is a vertical member (even if quite wide) in the middle of a rail and stile door. I do not state with any authority that ANY of these definitions are right or wrong. This is a term where I'm in the dark and am just reporting what I have read elsewhere. Here are some images of things that I have seen represented as muntins:

mushroom headed bolt --- synonymous with timber bolt

for images of wood itself, go here: wood id site

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY