The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

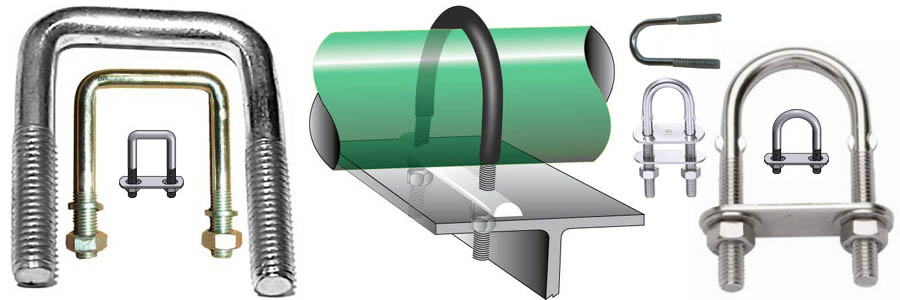

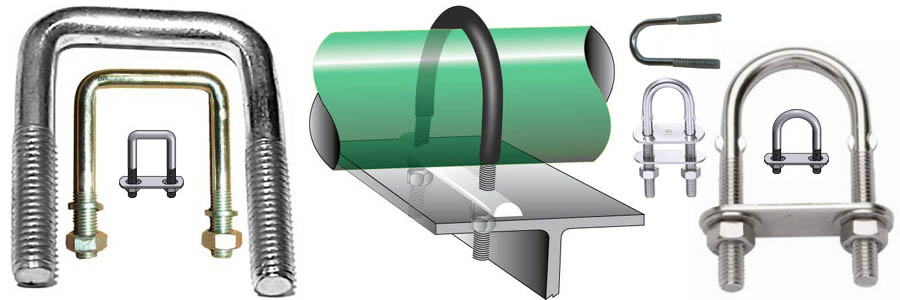

U bolt --- A length of rod that is threaded on both ends and then bent into a "U" shape which might be a very curved U or a more rectangular U. The curved variety in particular is used as a pipe holddown. Examples:

ulmiform --- Describes the wavy lines of pores always found in elms (genus Ulmus, thus the name ulmiform meaning "having the form of an elm" and often found in a few other woods such as honey locust, hackberry, redbud, etc. On the face grain (of elm in particular) this results in what I call a "feathering" when there is anything like a cathedral grain pattern. Examples of both end grain and the face grain feathering [note that "feathering" is not a widely used term, it's just what I call it because it is so descriptive]:

ultraviolet --- Also called just "UV", this is the portion of the sun's radiation spectrum above visible violet. It is what causes sunburn in people and it can be very damaging to coatings and sealants used on wood and can also have effects ranging from mild to dramatic on the color of unprotected wood surfaces. Most woods that are affected by UV get darker (e.g. padauk) but some get lighter (e.g. redheart) and many are hardly affected. A very few (e.g. purpleheart) have their color enhanced by exposure to UV. UV radiation is also used in UV curing of some finishing agents and adhesives.

ultraviolet blocker --- A characteristic of some wood finishing agents(such as spar polyurethane) that block the sun's ultraviolet rays. Without such a blocker, UV rays will cause some woods (padauk and redheart are excellent examples) to change color, usually in an unattractive way. Without a UV blocker, padauk darkens from a beautiful red or orange-red to a much less attractive brown and redheart fades from a vibrant red to a dull, flat brownish pink. Purpleheart, on the other hand, sometimes becomes a more vibrant purple when exposed to UV rays.

umbrella head roofing nail --- A form of roofing nail with an exceptionally large head to prevent pullthrough of roof shingles. As nearly as I can tell, these are widely used in Asia but not much in the USA. Examples:

unchucking --- Removing a workpiece from a chuck. The opposite of chucking.

undercoat --- The first coat of finishing agent applied to a surface after preparation (e.g. sanding). For metal surfaces, an undercoat is generally a rust-proofing agent. Compare/contrast to topcoat.

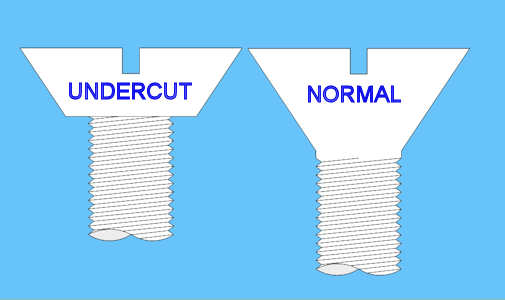

undercut --- (1) A wedge-shaped cut in a tree, used to guide the direction of the tree fall and to prevent splitting or kickback; also known as the facing cut. See fell.

undercut --- (2) In wood carving, this refers to cuts made in relief carvings that curve back under a projecting portion of the carving to give it high relief.

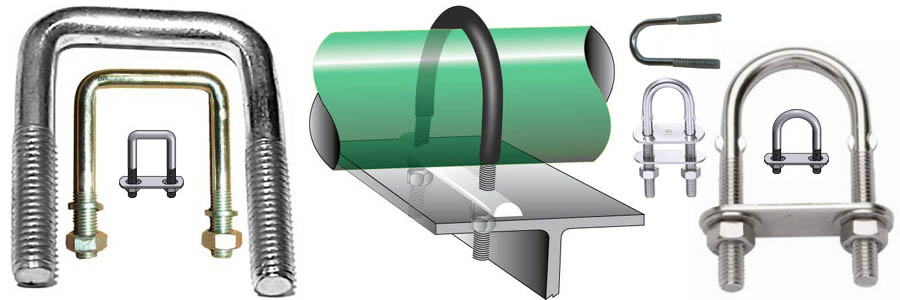

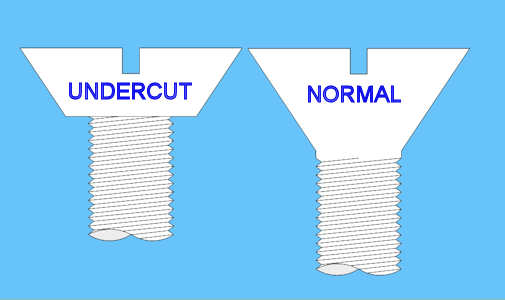

undercut screw --- A shallow-head countersunk screw or bolt, the point of which is to reduce the profile of the head and thus provide a little extra thread length for a given length of screw. Examples:

undercutting --- Cutting away thickness under, and back from, the edge of a plank or the rim of a bowl so as to increase the sense of relief or thinness; also known as "backing off".

underdriven --- Describes a fastener, such as a screw, not fully driven flush to the surface. Compare/contrast to overdriven.

Underlayment --- A layer of material used as a base material under flooring or roofing. In the case of flooring, the underlayment is generally thin water-resistant plywood but for roofing the term can mean plywood sheeting or it can refer to sheets of various kinds of materials, such as asphalt or plastic-based sheets that are present to provide a moisture barrier.

underrun --- The situation where a mill expects to achieve a certain number of board feet from a run but obtains less than expected. Compare/contrast to overrun.

understory --- Forest vegetation below the canopy.

Underwriter's Laboratories --- An independent, not-for-profit product-safety testing and certification organization. UL has tested products for public safety for over a century. Each year more than 17 billion UL marks are applied to products worldwide. You will find the UL mark on most woodworking power tools. There are a small number of other product-safety labs but in the USA none have the size or scope of UL.

uneven-aged stand --- A stand in which three or more age classes are each heavily represented.

unfinished --- (1) a plank that has not been surfaced; still rough-cut. Lumber yards typically charge a finishing fee of 10 cents to 40 cents a board foot for putting unfinished lumber through a surface planer.

unfinished --- (2) A wood product which still has to be sanded and/or have a finishing agent applied. For example, there are numerous outlets that sell unfinished (generally low-end) cabinetry that is then stained by the user to his or her liking.

uniform load --- A load that is evenly distributed over a given area. Compare/contrast to point load.

unit rise --- The number of inches a rafter will rise vertically for every 12 inches of run. See also total rise.

universal machines --- Over the years there have been a number of woodworking machines built that combine the functions of some combination of band saw, table saw, shaper, router, drill press, and more, all in one housing driven off of the same motor. They don't do any of the functions as well as single-purpose versions of those machines but they have the great advantage of taking up much less floor space than the combined single-purpose machines would. Purportedly, they are relatively easy to change from one function to another. There are also multi-function machines that are sometimes called universal machines even though they only combine a small number of similar operations.

unsanded panels --- Sheathing grade plywood panels designed for utility applications and left unsanded for economy.

unseasoned --- synonymous with green wood; wood that has not been seasoned.

unsound --- (1) see unsound knot

unsound --- (2) a term used to describe a board that has mechanical defects that mar the surface, such as checks and splits. Such boards would rarely be acceptable in construction situations and would likely have to be pared of the flawed area(s) in order to be used in craft projects except on occasions where a flaw can be used as, or as part of, an artistic effect. Burls would be a good example of such use, as they are frequently unsound but of high artistic value and never used for their strength.

unsound knot --- A knot which has cracks or voids or is noticeably softer than the surrounding wood due to decay. The opposite of sound. There is no implication in this term as to whether such a knot is tight or loose, but there IS an implication that such a knot will be visible under paint and therefore is unacceptable in many uses. Also, such knots are not allowed in many construction situations because they reduce the structural integrity of beams and they reduce the weather resistance of planks. Examples:

unstable --- Refers to wood that has not been dried to equilibrium with the surrounding atmosphere and which can be expected to move (change size) as it comes into equilibrium with atmospheric moisture content. Stability varies greatly with species; some species will have little movement regardless of moisture changes and others will have large movement with only modest changes in moisture. Also, it is very important to keep in mind that moisture is not the only factor in stability. Wood can be properly dried and in moisture equilibrium, but still be unstable, because it is tension wood. Compare/contrast to stable.

unstoried --- see storied

unsupported length --- The distance between the end supports, or intermediate bracing, of a column or beam.

unsurfaced --- Lumber that was not surfaced at the lumber mill. Synonymous with "rough sawn"

U-nut --- see spring nut

upholstery --- The covering, usually cloth or leather, on a piece of furniture such as a chair or sofa. Some definitions include only the cloth and any padding underneath the cloth, and other also included both of those plus any springs that may be under the padding.

upholstery hammer --- synonymous with tack hammer

upholstery nail --- Also called "upholstery tack", this is a small, thin-bodied nail, usually 1/2" to 3/4" long and with a very broad head. The head most often is domed and frequently has some sort of design on it, sometimes quite elaborate. Sometimes the head is in the shape of a pyramid or other shape that would not be found on any other kind of nail because these nails are used to affix upholstery to chairs and other padded furniture and thus are as much decorative as functional. Examples:

uprooted --- Refers to trees that have been pulled out of the ground, either deliberately (if done by a human, this has to be a VERY young tree) or by a wind storm.

urban wood --- Refers to Used pallets, wooden shipping crates and clean construction wood diverted from land fills or other waste disposal and recycled, usually by being chipped for use in making particleboard and mdf.

urethane --- An elastic, petroleum based varnish commonly used to prefinish products at the factory, but also used on unfinished products at the job site. In modern times, urethanes are modified with additives to affect drying time, durability, and clarity. Currently, aluminum oxide modified urethanes are one of the most common varnishes used on prefinished products. Respectively, oil-modified urethanes are the most commonly used site applied finishes; acid-cure urethane (Swedish Finish), moisture-cure urethane, and water-based urethane are also used on today's unfinished floors. Compounds that include complex urethanes are sold as polyurethane finishes and they tend to be quite hard and durable and waterproof and they can be had with UV blockers to protect wood from color changes due to sunlight. Compare/contrast to other finishing agents.

urn --- A vase-like vessel, ordinarily with a top over an upper opening but without handles and with a foot / pedestal of some kind. In wood turning the terms urn, vase, vessel, and hollow form are somewhat sloppily interchanged and I have described some of the distinctions with the term lathe turnings. Examples:

USDA --- The United States Department of Agriculture, one portion of which, the Forestry Service, has numerous publications on wood and trees. I recommend you poke around at USDA's Forest Service.

utility knife --- A the name suggests, this is a general purpose "knife" (also known as a "box cutter") that is usually made up of either a single one-edged razor blade or a strip of snap-off razor blades, and in either case, encased in a metal or plastic handle with a slide mechanism that allows adjustment of the blade depth. Most commonly used to slice open cardboard boxes (thus the name "box cutter") but has lots of other uses. Examples:

UV --- an abbreviation of ultraviolet

UV absorber --- synonymous with ultraviolet blocker

UV blocker --- synonymous with ultraviolet blocker

UV curing --- A complex chemical process using UV light exposure to cure finishing agents or adhesives.

vacuum chuck --- A lathe chuck in which a vacuum system is attached to the rear of the headstock and the workpiece is held in place by atmospheric pressure (see PSI.

vacuum press --- A "clamp" than consists of a vacuum pump pulling the air out of an area under a perforated plane that has is under a workpiece topped by veneer or whatever needs to be clamped to it, and then the whole thing topped by a nonporous membrane such as a sheet of plastic or rubber. The vacuum under the workpiece means that it has no air pressure on the bottom but a full 14.7 PSI on top. This works out to over 2,000 pounds of pressure per square foot, so is quite a strong clamp.

valley --- An area where two adjoining sloped roof planes intersect on a roof creating a "V" shaped area.

vapor --- Airborne particles of moisture or of material that evaporates off of the surface of a finishing agent or other chemical.

vapor barrier --- A material (such as plastic film) which controls moisture transmission through roofs, walls, and other building elements. Often combined with insulation to control condensation. A vapor barrier should be installed just inside the warm wall. See also moisture barrier.

vapor transmission rate --- The rate at which moisture passes through a material or coating.

variable speed reversible drill --- A power drill that has a speed control and the ability to reverse the direction of spin. VERY handy for putting in and taking out screws (using a screwdriver bit instead of a drilling bit). These tend to be a little more powerful than the standard power drill and also usually have a second handle rod that projects out of the side to give you a very firm two-handed grip when using the tool to tighten nuts or screws or when using large boring bits. Examples:

varnish --- A somewhat vague term, denoting a substantial number of different compounds that are used as (among other things) wood finishing agents. Varnishes are a complex topic that in detail is beyond the scope of this first cut at this glossary. The common characteristics of such compounds are that they provide hard, durable, transparent (although there are formulations that contain color) finishes that are waterproof and resistant to chemical stain. They are usually applied in thin layers. Shellac and polyurethane are types of varnish. There are some formulations that protect against ultraviolet rays that could otherwise cause color changes in wood. Compare/contrast to other finishing agents.

vase --- A topless container with a round cross section (when taken horizontally) generally used to hold flowers. In wood turning, vase is a term used for items that you might also see called a vessel or a hollow form, but loosely, the definition is that it is a turned form where the height is more than the maximum diameter (often quite a bit more) and the opening is anything from the maximum diameter to a little less than the maximum diameter. If the opening is significantly less than the maximum diameter, it's a hollow form. A slim vase with a top would be an urn. The difference between "bowl" and "vase" is sometimes debatable and the difference between "urn" and "vase" is not debatable only because an "urn" has a lid and a vase doesn't. Compare/contrast to other lathe turnings. Examples:

vaulted parallel chord truss A parallel chord truss that is used at a slant so that although the chords are parallel, they are not horizontal. For an example, see parallel chord truss.

vbelt --- A trapazoidal cross section endless-loop belt made of strong but flexible material and designed to run in pullys that have "V" shaped grooves. Used with pully wheels to transmit power from a motor shaft to the shaft of a power tool such as a wood lathe. V belts are more stable, and transmit more power for a given width, than flat belts because the have a greater surface area touching the drive wheels.

V block --- A piece of wood with a V-shaped groove cut into one face to securely hold dowels or other rounded objects in position while performing operations such as drilling.

Vehicle --- The liquid portion of a finishing agent in which the pigment is dispersed. The components of the vehicle are typically a binder and a thinner.

veneer --- A thin sheet of wood, generally ranging from 1/60"thick to 1/16" thick, produced by peeling or slicing, or rotary cutting, wood from a veneer log. The "standard" thickness in the USA is 1/42" thick. Thinner veneer are sometime made, all the way down to 1/100" and thicker softwood veneers up to 1/4" are used in the manufacture of plywood. In use, often the veneer of an expensive wood is bonded to a substrate of much less expensive wood or composite material to give the impression that a piece of furniture is made from the expensive wood. Another reason for using a substrate covered by an expensive veneer is that the substrate is likely to be much more dimensionally stable than would be solid wood. There is a process, called marquetry, by which pictures are created by cutting out small pieces of different colored veneer and putting them together to form the picture. Veneer sheets are seasoned after slicing.

Veneer slicing techniques are ... MORE.

Examples of veneer:

veneer banding --- see banding (both definitions)

veneer core plywood --- plywood made from three or more pieces of veneer glued up in alternating grain patterns. This is "normal" plywood; that is, it's what people normally mean when they say plywood, and it's what you see at the local hardware store. Contrast with lumber-core and particleboard-core.

veneer hammer --- a heavy metal plate, usually attached to a handle, as though it were a hammer, and used to smooth down veneer once it has been glued to the substrate (and, of course, before the adhesive has set). Examples:

veneering --- Facing an inexpensive substrate with a thin layer of much more expensive ornamental wood veneer.

veneer lathe --- A machine on which logs are peeled to yield veneer for plywood or to produce decorative veneers with a swirly figure. See rotary cut

veneer log --- A high-quality log, of a desirable species suitable for conversion to veneer. Veneer logs must be large, straight, of minimum taper, and free from defects. Less than 5% of all logs are of veneer quality. Although veneer logs are sold by the board foot just like regular logs, they are never converted to lumber since they produce much more value as veneer.

veneer matching --- There are various ways in which sheets of veneer can be placed next to each other ("matched") to give various patterns. These are used to enhance the look of a panel or set of panels and you will often see one of these used on the walls of the reception areas in high end companies. The most common are:

veneer saw --- A thin-bladed, fine-toothed saw for cutting and trimming veneer. Such saws are small and normally have a curved blade that allows one to begin sawing in the middle of a sheet of veneer if so desired. Because veneer is so thin, such saws do not make a distinction between ripping and crosscutting, although you DO need to be a litte careful when using them to cut across the grain in the veneer since you could cause some splintering if you're not careful; usually this isn't a problem since these saws are sharp and have a very fine-toothed edge. Examples:

veneer slicing --- One of the two main methods for producing veneer from logs, this consists of mounting a log on a large plate and using a strip of metal that looks a lot like a seriously oversized razor blade to slice off thin sheets of the wood. The other form of veneer production is rotary cutting.

ventilation --- the passage of air in and out of an enclosed space. In woodworking this is used as regards the flow of air in a roof (see soffit ventilation, the flow in and out of a workshop, and the flow of air around hazardous chemicals. You want to be in an area with good ventilation if you are using certain finishing agents.

vent stack --- synonymous with plumbing vent

vernier calipers --- This form of calipers has an inner section that looks like a narrow ruler and outer sections that slides along it, and it has downward (and usually also an upward) pair of flat-edged projections. The projections are moved until they are at the distance to be measured, which can then be read on the scaled markings on the inner section. The word vernier comes from the French mathematician who invented this kind of sliding scale. Vernier calipers are more accurate than transfer calipers because the finely printed scale markings give better accuracy than the normal ruler to which transfer calipers transfer their measurements. They are less accurate, however, than their improved sister device, the dial calipers. Examples:

vertical --- Straight up and down relative to gravity. If you hang a weight on one end of a string and hold the other end, the string will be vertical. That's the methodology of a plumb bob

vertical grain --- A way of describing quartersawn planks that emphasizes the fact that the grain runs perpendicular to the face. It is also used to emphasize the fact that (being quartersawn) the grain lines run up and down a plank and a fairly parallel to each other.

vertically laminated timber --- Laminated timber designed to resist bending loads applied parallel to the wide face of the laminations. For vertical loads (loads due to gravity), this means that the wide face is oriented vertically.

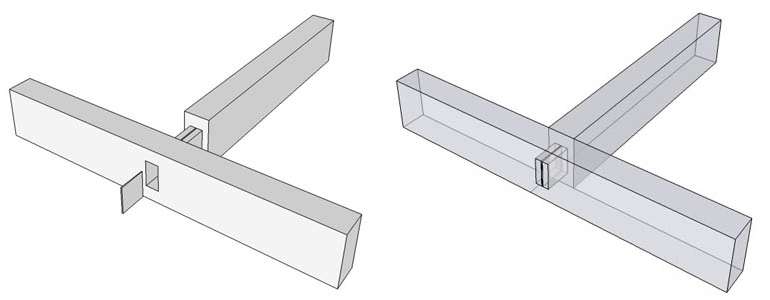

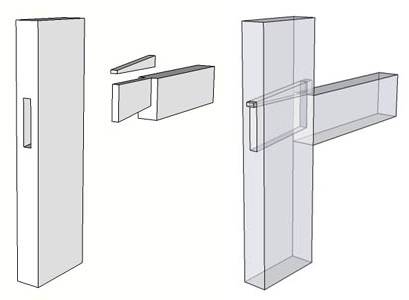

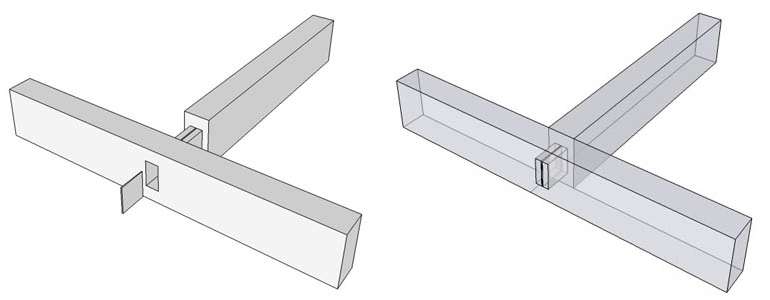

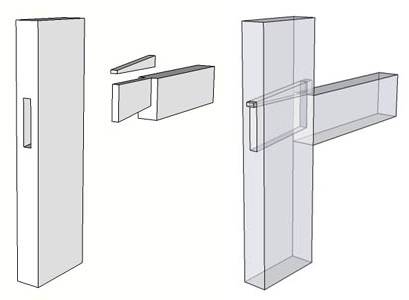

vertically wedged mortise and tenon --- When it is useful to use a wedged mortise and tenon to join two horizontal members, the wedging construct is exactly like that of a standard wedged mortise and tenon but because the piece with the mortise is horizontal, the wedge is turned to a vertical orientation. Use of a horizontal wedge in this situation would have the wedge putting pressure laterally on the piece with the mortise (up and down would be the lateral direction in this case), and thus would likely cause a split in that piece. Examples:

vessel --- (1) A conductive tube in hardwoods. Although these act like long soda straws to carry liquids in the tree, they are actually discontinuous, being made up of vessel elements, which are short tubes that have ends that are open to each other so that taken together they form the water-carrying capability of hardwoods, similar to the function of the tracheids in softwoods. The open cross section of one of these tubes is called a pore and pores figure strongly in the appearance of the grain in hardwoods. Softwoods don't have vessels, and thus don't have pores.

vessel --- (2) The name given by wood turners for turned items that are somewhat tall relative to their width and are hollow. They are much too tall to be called platters, and generally are too tall to be called "bowls". It's a somewhat vague term and any one item might be called, by different turners, a bowl, a vase, a vessel, or an urn. I have even seen turners call almost identically shaped items a "bowl" on one page of their web site and a "vessel" on another page. Also, there does not seem to be any implication as to whether the opening at the top is quite large or quite small. A similar vague term, although generally restricted to items with a small opening at the top, is hollow form. Compare/contrast to other lathe turnings.

vessel elements --- see explanation with the term vessel

V groove --- Narrow and shallow V or U shaped channels routed on a plywood face to make the face appear to be V jointed planking. For an illustration, see tongue and groove.

vice --- synonymous with vise

vine mark --- Bands of irregular pattern running across or diagonally to the grain which are caused by the growth of climbing vines around a tree. Although I understand this conceptually, and believe it can happen, I have never knowingly seen directly, or even in pictures, a sample of such a mark.

virgin forest --- see old growth forest

virgin timber --- see old growth forest

viscometer --- Any instrument used for measuring a liquid's viscosity.

viscosity --- The extent to which a fluid resists the tendency to flow. In woodworking, this is a term that you'll see in discussions about finishes and glues in addition to wood sap and resins. Viscosity is mainly dependant on the chemical composition of a compound, but is also affected by temperature, with heat decreasing viscosity in pretty much all chemicals, and cold raising viscosity. That is, hot fluids flow more freely than cold fluids of the same composition. The phrase "slower than molasses in January" reflects the fact that molasses is a high-viscosity fluid and flows very slowly in normal times and in January, basically not at all.

viscosity meter --- A device for measuring the flow rate of a fluid. In woodworking, the most common of these are the Ford cup and the Zahn cup, which are both used in measuring the flow rate for paints and other finishing agents.

viscous --- having a high viscosity; slow to flow.

vise --- [also vice] A clamping, jawed device that holds a work piece. Every trade, including woodworking, has specialized vises suited for their particular needs. The types of vises used by woodworkers include: NOTE: INCOMPLETE SECTION --- many of the terms below are not yet defined

- bench vise --- see woodworking bench vise and machinist's bench vise

- carpenter's vise --- attaches to a sawhorse

- carver's vise --- for carving (attaches from the bottom)

- drill press vise --- for use with a drill press

- electrician's vise --- for use on electrical items

- end vise --- bolted under the end of woodworking bench

- machinists bench vise --- bolted to benchtop in a machinist's shop

- miter vise --- for use with miter cuts

- picture frame vise --- same as miter vise

- pipe vise --- designed to hold round pipes

- quick release vise --- woodworker's bench vise or end vise with a quick release mechanism

- table vise --- clamps to a workbench or work table

- toggle vise --- same as toggle clamp

- vice cheeks --- a part added to a woodworking bench vise

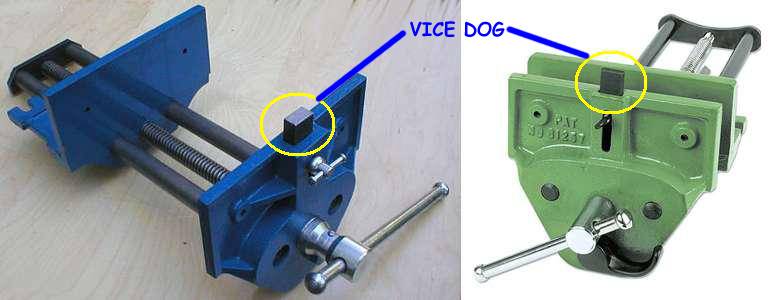

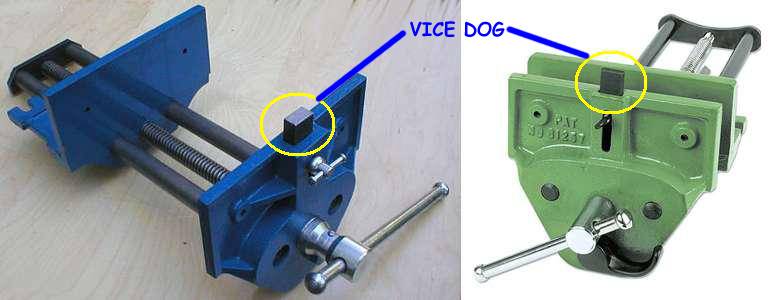

- vice dog --- part of a woodworking bench vise

- woodworking bench vise --- bolted under the edge of a woodworking bench

- see also clamps

vise cheeks --- sacraficial planks used to protect workpieces from the metal jaws of woodworking bench vises. Most woodworkers permanently mount the cheeks to the jaws, but I have a couple on a shelf next to my bench vise and only use them when needed and then put them back on the shelf. This gives me an extra 1 1/2" width capacity in the vice, and I sometimes need it. Examples:

vise dog --- A small, strong metal tab that can be pulled up above the top surface of the outer jaw on a woodworking bench vise so that the vise can be used to put pressure on a work piece that is flat on the top of the bench (bench vises are normally mounted just below the bench top at the edge of the bench and thus without the tab would not be able to clamp anything at the level of the bench top. It is common for bench dogs and/or bench stops to be used to provide the clamping force at the other side of the workpiece from the vise dog. Examples:

Vise Grip pliers --- A brand of pliers most famous for its locking pliers but the Vise Grip company makes all types of pliers. If you hear pliers referred to as Vise Grip pliers, most likely the reference isn't to the brand but to a pair of locking pliers.

V joint --- (1) A term used in plank flooring to indicate that edges are beveled so that there are not sharp divisions from one plank to the next that would snag objects if the surfaces of the planks were not exactly level with each other. So-called because a cross section of such a joint looks like the letter "V". The term is also used with wall paneling that is made of planks when they are similarly beveled. Sometimes wall paneling that appears to be V-jointed planking is actually V-grooved plywood.

V joint --- (2) a tongue and groove joint but using V shaped tongues and grooves instead of the normal rectangular shapes.

VOC --- volatile organic compound

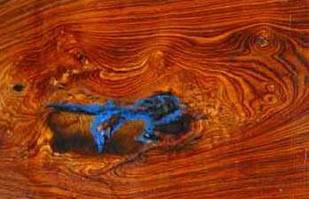

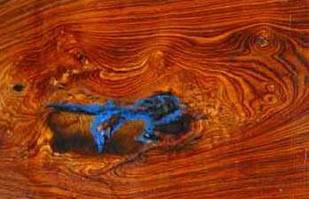

void --- As regards woodworking, this refers to an empty spot in wood, which may have been created by the presence of a now-empty gum pocket or, particularly in burls, just as an area where there is an open space in the growth. The most likely place of all to find voids in wood is in root burls. A knothole is a particular kind of void but would not normally be referred to as a void simply because it has its own more specific name. Here is an example of a large void in a cocobolo plank (the blue is from the cloth behind it). This might have been some form of knothole but it is so amorphous that I doubt it would be referred to as a knothole even if it were definitely known to be such, more likely just as a void.

volatile --- (1) As regards woodworking, this refers to the characteristic of some chemicals (e.g. wood finishing agents or cleaning agents or components thereof) whereby they readily evaporate at normal temperature and pressure. Alcohol, for example, has high volatility, molasses has low volatility. Often, finishing agents have a volatile component that is a solvent or a thinner and such volatile elements tend to be flammable.

volatile --- (2) A characteristic of Italian women.

volatile content --- The percentage of materials which evaporate from a finishing agent. The solvent portion of a finishing agent.

volatile organic compound --- [VOC] Any carbon compound that evaporates ["out-gasses" or "fumes"] under normal conditions. Essentially, all solvents except water are classified as VOCs. Some government agencies are limiting the amount of VOCs permitted in finishing agents because of concerns about environmental and health effects.

volitility --- The extent to which something is volatile

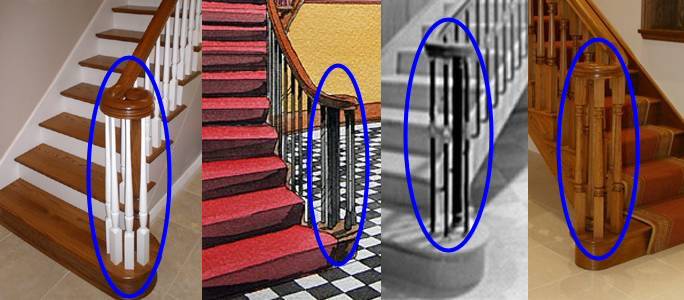

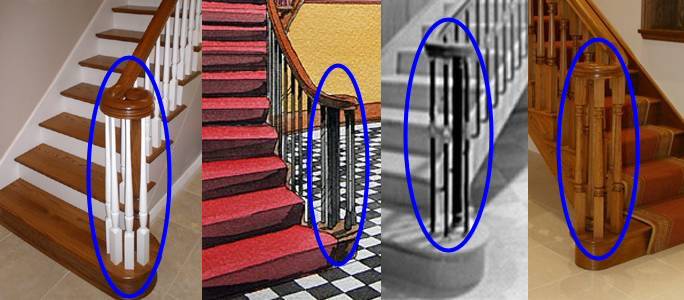

volute --- A spiral shaped handrail extension at the bottom of a staircase. It sits on top of a bullnosed step and the spiral may be right- or lefthanded depending on which side of the stairs they occur on when facing up the stairs. In the composite pic below, I have mistakenly circled both the volute and the balusters which would seem to imply that they as a unit are called the volute, but that's not correct. The volute is just the top part. Examples:

VS --- Variable Speed; just refers to any machine that has a variable speed control, particularly for machines, such as a drill press or a wood lathe, that may come with either fixed speed or variable speed. "Fixed speed" in such cases doesn't mean ONE fixed speed; such machines usually have a belt system that allows for numerous different speeds, just not continuously variable as is the case for VS machines. Also, on VS machines you can vary the speed while the machine is running (in fact you often can ONLY vary the speed if the machine is running) whereas on non-VS machines, the machine has to be off, and should be unplugged for safety, while you change the belt positions.

VSR --- Variable Speed Reversible; See variable speed reversible drill.

vulnerable --- see conservation status

waferboard --- A panel product of wafers of wood bound together by resin, heat, and pressure; can be made of species not suitable for lumber or plywood production, and can be made from wood scraps too small to use in plywood. Unlike with oriented strand board, which is a similar product, the wafer alignment is random, but parallel to the surface in flatness, so such panels tend to have equal strength in all directions parallel to the surface.

wainscoting --- When the lower and upper sections of an interior wall are finished differently and/or divided by a chair rail, the lower section (usually about the lower third of the wall) is called the dado and the covering used on that section is called wainscoting. Traditionally, it was done with oak panels but wainscoting can be any material; the definition depends on position, not material. Originally, wainscotting was used to insulate stone walls, both thermally and aesthetically, but today it is purely aesthetic (unless you happen to live in and old stone castle). Examples:

waler --- Horizontal or diagonal timbers used to brace the sections of wood used as concrete pouring forms, or to brace and stiffen wall framing.

wallboard --- synonymous with drywall

wall plate --- synonymous with top plate.

wall stringer --- see stair stringer

wane --- An edge of a sawn board where the bark or surface of the trunk remains or a missing, underbark-covered, area at the edge of a sawn board where there used to be bark. That is, wane is the result of a saw-cut including an area of bark, whether or not the bark actually remains on the cut plank. See also, want. Here's a pic showing osage orange and dogwood both with wane where the bark is extant:

waney --- see wane

want --- The absence of wood, other than wane, from the arris or surface of a piece of timber. You will sometimes see the phrase "no wane or want" meaning that the wood in question has no missing areas in its edges.

warm wall --- In buildings, the wall between inside and outside is often made of several layers, usually including an inner wall, a framing structure, and an outer wall, and the inner and outer walls may themselves have layers. The innermost layer of that whole structure is called the warm wall.

warp --- (1) Distortion of a tool, such as a circular saw blade which then develops wobble, or distortion of part of a tool,such as the handle.

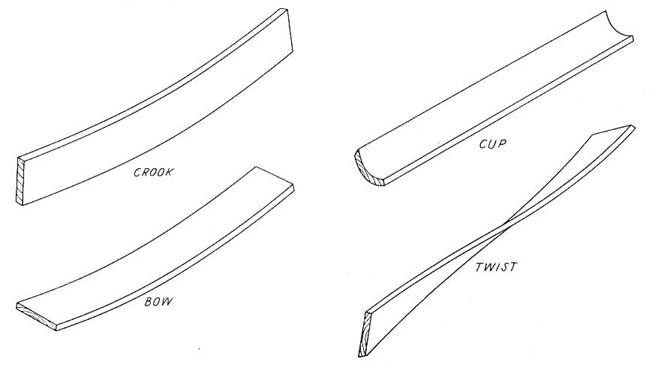

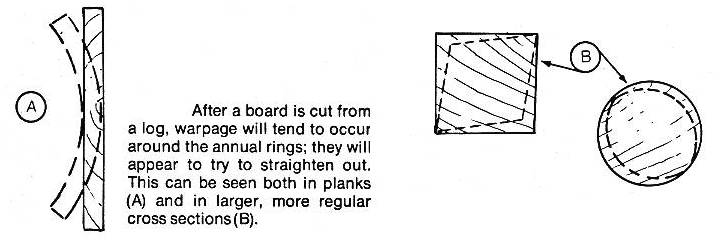

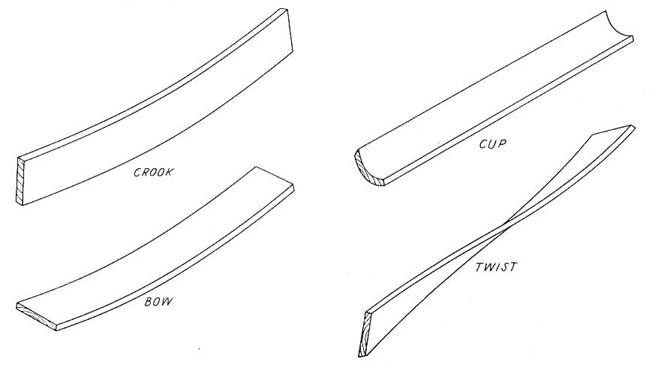

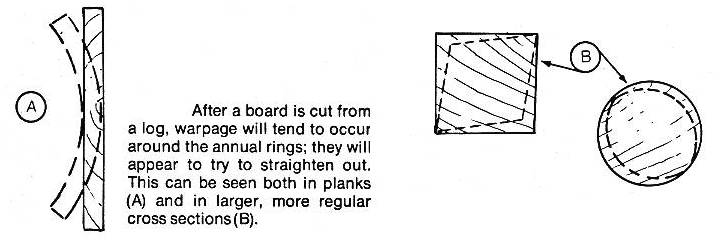

warp --- (2) a drying defect in which one or more area of the wood moves away from the position it has when the plank is flat and rectangular. Specific types of warp have their own names. These include: bow, crook, cup, and twist, and it is not unusual for a warped plank to have a combination of these defects. As wood dries, there is a tendency towards movement that would cause the tree rings to become more straight, as shown in the second drawing below. The resulting common forms of warp are shown in the drawings directly below:

washboard --- Describes the surface of a plank where the planer makes tiny groves (technically, called knife marks) across the face; looks like an old-style corrugated washboard. In the example below, a tulip poplar plank not only shows washboarding, it also shows the kind of tearout that a planer will make when the grain points up into the blades. This section of the plank was next to a knot, part of which is visible, so it had irregular grain which is particularly susceptible to planer tear.

wash coat --- A coat of highly thinned finishing agent used to partially seal a wooden surface before a dye, stain, glaze, or toner is applied. The washcoat provides a base for more uniform coloring. Often a light sanding is required after applying a washcoat because it raises the grain. See also wash primer.

washer --- A device, usually metal, with a hole in the middle, used under the heads of bolts and screws to distribute force more evenly and widely from the head of onto the surface under the head. Other shapes and materials for washers are used to provide seals, locking mechanisms and vibration reduction. Typical washers have an OD about twice their ID, but fender washers are a notable exception to that rule of thumb, and most types of lock washer have a smaller OD than others. Similar devices are the gasket and the O-ring. Types of washer likely to be encountered by woodworkers include:

- countersunk --- for countersunk screws

- countersunk lock washer --- an external tooth lock washer but cone-shaped to conformm to the bottom of a countersunk screw

- cup washer --- same as finish washer

- dished --- not used in woodworking

- dock --- very heavy-duty fender washer for heavy construction (such as marine docks)

- external tooth lock --- lock washer with teeth pointing outward for maximum surface grab

- finish washer --- used with countersunk bolts and screws but without the countersunk hole

- flat --- "common" type, like a featurless dime with the center punched out

- fender --- very large OD for use with thin material (like a car fender, thus the name)

- flanged countersunk --- like a countersunk but with a flange to distribute the pressure even more

- flush --- like a flat washer but the center is pressed down into a cone shape to conform to the underside of a countersunk screw

- internal-external tooth lock --- toothed lock washer with both internal and external teeth

- internal tooth lock --- lock washer with teeth pointing inward for appearance

- lock --- see split ring lock, external tooth lock, internal tooth lock, and internal-external tooth lock

- mudguard --- same as fender (mudguards are thin material, thus need a fender washer)

- ogee --- wide, thick, cast iron, ogee-shaped washer used in heavy construction

- phenolic --- insulating, for use in electrical connections

- plate washer --- used in attaching sill plates

- round plate --- see plate washer

- serrated --- synonymous with toothed

- shoulder --- an electrically-insulating bushing

- split ring lock --- a flat washer split and bent to provide the locking pressure

- split washer --- same as split ring lock washer

- spring --- generally synonymous with split lock but may be used as synonymous with wave

- square plate --- see plate washer

- square --- like a flat washer but with a square rim

- star --- a little-used synonym for external toothed, because of the appearance

- torque washer --- for use with carriage bolts only

- toothed --- see internal tooth, internal-external tooth, and external tooth

- trim washer --- same as finish washer

- wave --- locking type with a wave shape to provide a spring-like holding action

- multi-tooth --- synonymous with internal-external tooth

- star --- synonymous with external tooth lock (because of the shape)

washer head screw --- A type of wood screw that has an extra-wide head that acts as both a washer and a head. These are sometimes seen in machine screws as well, but are much more common in wood screws which need the extra holding power. Examples:

wash primer --- A thin paint designed to promote adhesion or to be used as a barrier coat. See also wash coat.

waste --- wood that will be removed in the finished work, often retained during working as a handle or gripping surface that does not have to be protected from marring. See also horn.

waste wood --- (1) The sides of logs that are cut off as the cant is formed. These planks are flat on one side and curved on the other. They rarely actually go to waste since at the very least they are used for wood chips to create composite materials and also they are sometimes cut up to make small planks and slats.

waste wood --- (2) Any wood that is cut off of the ends/edges of planks as a workpiece is cut to final form. This so-called "waste wood" is often put to use as small elements of jigs and other general use around the shop, or it is otherwise made good use of in the barbeque pit.

wasting --- Quickly removing wood during carving, usually with an adze, knife, or rasp.

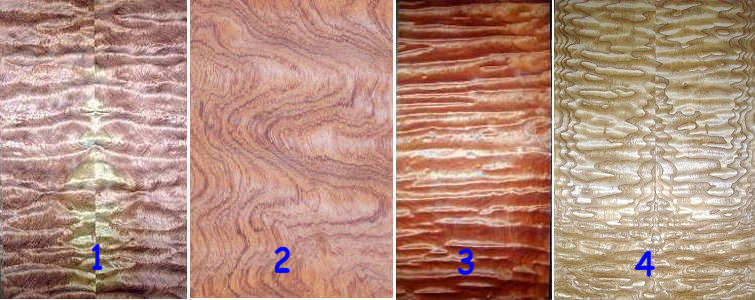

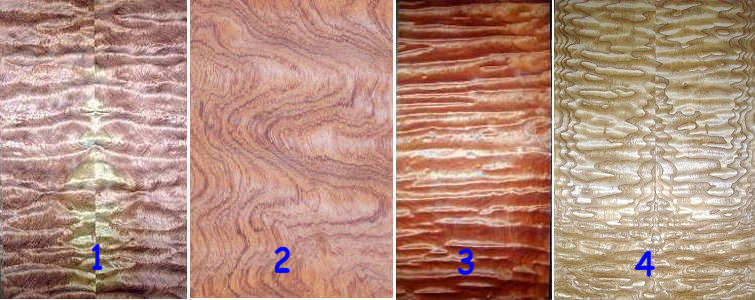

waterfall figure --- A term used rather loosely, and at the discretion of any vendor who cares to use it, for two different wood figures. The first is a quilted figure that would legitimately be called just "quilted" but which vendors like to call waterfall. This is used almost exclusively with quilted bubinga but I have seen it used by some vendors for other pieces, albeit rarely. A couple of examples (makore and tamo) are shown below. The other use is for kevazinga which is rotary cut bubinga that has no quilt at all but which can have very swirly grain lines what, with what I can only see as a HUGE amount of imagination, could be interpreted as looking a bit like a waterfall or like a quilted piece and which really should be called "swirly figure", not waterfall. Examples of pieces that were labeled as waterfall: (1) quilted bubinga, (2) swirly figure kevazinga (rotary cut bubinga), (3) quilted makore, and (4) quilted tamo

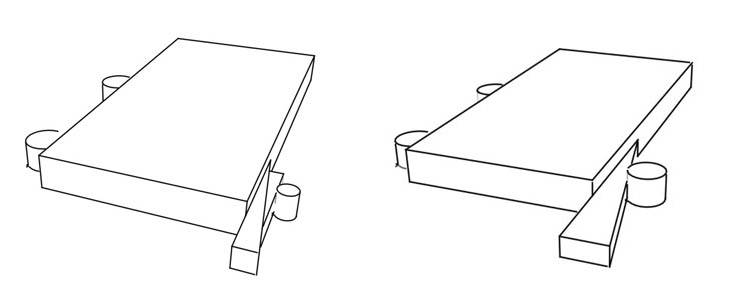

waterfall table --- A table that looks exactly like an upsidedown U, although the proportions may be wider than the letter U. Waterfall tables are sometimes mistakenly identified as a parson's table. Typically, these tables, when built of wood, are built with good joinery at the corners and do not have anything like an angle iron in the bottoms of the corners. They are frequently built with plexiglass, plastic, or metal. Examples:

water logging --- The process whereby a material, including wood, becomes totally saturated with water. When this happens to lumber that is floating to a processing mill, the logs sometimes sink, and in any event are referred to as wetwood, not to be confused with green wood (unseasoned wood) which is not fully saturated with water, although in some species, the green wood can be close to water logged.

water repellent preservative --- A water repellent chemical that also contains a preservative. After application to wood and drying, this compound makes the wood resistance to attack by fungi or insects and also makes the wood less likely to absorb moisture from the atmosphere, thus reducing the likelihood of both decay and movement in service.

water stain --- Discoloration of wood caused by water, which can cause movement and/or evaporation of the color-creating pigments in wood.

water stone --- A type of sharpening stone with which water is used as both as a lubricant for the sharpening process and to create a slurry to carry off the swarf as the sharpening progresses. Although oil stones can use water as a lubricant, water stones will be damaged if oil is used with them.

Watt --- A measurement of electrical power. Watts are computed by multiplying volts (a measure of electrical potential) times amps (a measure of electrical current flow), so in a standard wall power circuit with 110 volts, 1 amp produces 110 Watts, or stated another way, to power a 110 Watt device requires one amp. Thus a standard 100-watt light bulb requires just under one amp. Another popular measure of power is horsepower, one of which is equivalent to 746 Watts, so a one horsepower motor in a 110 volt circuit will draw 746/110 = 6.7 amps. Another interesting number to note is that most home circuit breakers trip at 15 amps, which means the circuit can supply only 15x110 = 1650 Watts before tripping, and 1650 Watts is 1650/746 = 2.2HP so if you have a 3HP motor, you need a "220 Volt" circuit (which is actually about 208 volts) .

wave washer --- A type of lock washer that has as the locking mechanism the fact that the washer (which is otherwise a thin flat washer) is bent in a wavy fashion so that it creates a spring-like clamping pressure between the bottom of the bolt or screw and the surface being clamped. Examples:

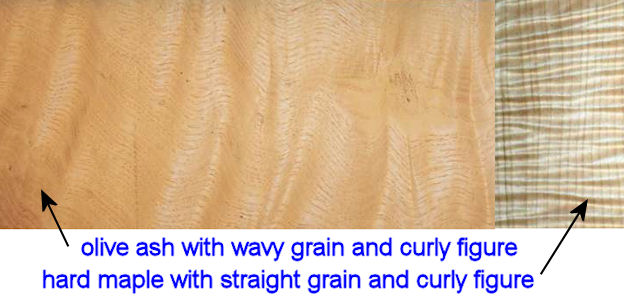

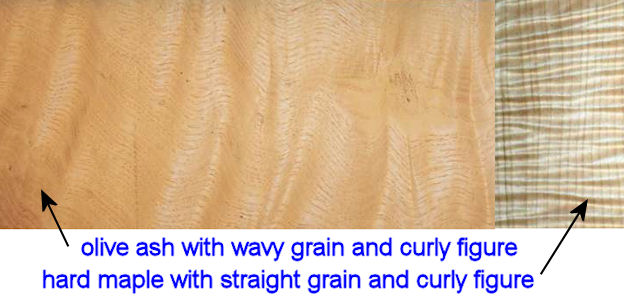

wavy figure --- This term is often used as synonymous with curly figure (and even fiddleback, but is also used to describe a more gently curled figure that can either be just a very mild curly figure or can be specifically the result of wavy grain.

wavy grain --- [also curly grain] A form of grain in which the wood fibers run in a wavy pattern rather than the normal straight up and down the trunk. This sometimes results in curly figure but more often it does not. Here's an example of a piece of olive ash that has wavy grain and curly figure, compared to a piece of hard maple that has straight grain and curly figure to show the difference between curly GRAIN (which should really be called wavy grain) and curly FIGURE which may have nothing to do with wavy grain:

wax --- An ambiguous term referring to any one of a large number of chemical compositions that have characteristics at least fairly similar to the natural substance "beeswax"

which is created by bees in constructing their honeycombs. Some waxes are natural secretions of plants or animals, some are produced as petroleum distillates, and some are completely synthetic constructs much like plastic. Waxes are used as (among many other things) wood finishing agents and they share the common characteristics of (1) being plastic (malleable), (2) having a higher viscosity than most wood finishing agents (some are in the form of a semi-solid paste), and (3) being totally waterproof. Wax is usually applied and maintained in thin layers which are buffed for a shine (much like waxing a car) and while a wax finish is easy to apply and maintain, generally looks great, and has the advantage of being waterproof, it is not a hard, durable surface and does not do much to protect wood from wear. Compare/contrast to other finishing agents.

ways --- The bed of a wood lathe normally consists of two rails of either metal or wood. The rails are technically called the "ways" and while it is technically correct to speak of one of them as "a way", it would be more normal to call one of them "a rail".

weatherboard --- Boards that cover external surfaces and overlap them to keep out rain.

weathering --- Mechanical and/or chemical disintegration and discoloring of the surface of wood in exterior use, caused by exposure to light, the action of sand and dust carried by the wind, and the alternate shrinking and swelling of surface fibers with the continual variation in moisture content brought by changes in the weather. Weathering does not include decay in wood, but is sometimes used also to refer to changes in surface finishes due to the effects of weather.

weatherstripping --- Any of a number of artificial materials manufactured in long strips (and usually sold in rolls) used as a seal around doors and windows to reduce air movement through the joint (and thus to prevent the internal conditioned air from mixing with the hotter or colder external air).

web --- Any horizontal stiffener such as might be found in a box beam, truss, T beam or I beam.

wedge --- (1)[noun] One of the 6 simple machines of classical mechanics, the wedge is just a long object that is wider at one end than the other. It can be used to separate objects, lift an object, exert clamping pressure, etc. The simplest form of use of the wedge in woodworking is in the splitting wedge. The wedge applies the principle of mechanical advantage, most often to trade distance for force although it also changes the direction of a force. For example, when you exert 50lb of force to move the point of contact of a wedge from a point where it is 1/2" wide to a point 5" further down the wedge where it is 1" wide, you have moved the wedge 5" and the object it is wedging by only 1/2" thus providing a force multiplier of 10, so if you smacked the wedge with 50lbs of force, the object receives 250lbs of force; that's what splits logs with a splitting wedge. Also, of course, with a splitting wedge, you would be applying a force downward but the log gets a sideways force coming off of the wedge. Pairs of wedges used together in cabinetry are called "folding wedges" (see, for example, tusked mortise and tenon with folding wedges.

wedge --- (2)[noun] see splitting wedge

wedge --- (3)[verb] To modify the size and/or direction of a force using the action of a wedge (see noun definition above)

wedge clamp --- A clamp in which a wedge (actually it is most commonly a PAIR of wedges), is used to create a clamping pressure. Examples (these assume bench dogs at fixed intervals with a wedge clamp to provide holding pressure on the workpiece, but wedge clamps can be used in a variety of situations):

wedged --- see wedge

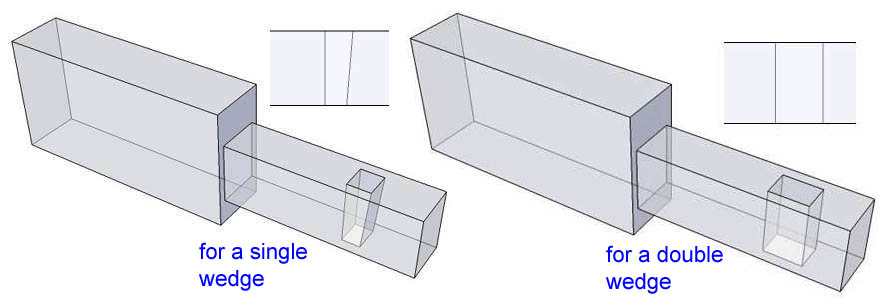

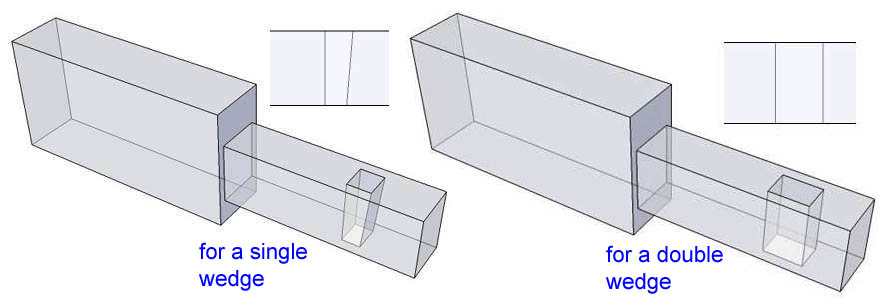

wedged mortise and tenon --- Although this term is sometimes used to describe the tusked mortise and tenon, that is a different joint entirely and the term "wedge" more properly refers to the use of one or more wedges, inserted in the tenon of a through mortise and tenon to provide extra holding power. If a blind mortise and tenon has a wedge in the tenon, that is called a foxtail wedge. Here are some common types of wedged and tusked mortise and tenon joints that are illustrated in this glossary:

wedged tenon --- A mortise and tenon joint that has one or more wedges put into the end of the tenon. The term is also, somewhat confusingly, used to refer to tusked mortise and tenons which is a totally different use of wedging. For illustrations, see the terms listed under wedged mortise and tenon.

wedged through dovetail tenon --- This is a mortise and tenon joint in which the mortise is cut out at a slant and the tenon is cut as a half-dovetail pin and a wedge is used to fill the rest of the joint. This is a strong joint in terms of its resistance to pullout of the tenon, but unless I am missing something, the construction technique presented in the illustration is simply moronic. I put it in that way because that's the way it was illustrated in the book where I found it, BUT simple physics makes it clear that reversing the wedge (and making the mortise a full dovetail shape) makes for a joint that is MUCH more resistant to tenon pullout, especially if this is done as a knockdown joint. The example below is shown as a knockdown joint with the wedge extending outside the mortise on both ends:

wedge mortise --- When doing a tusked mortise and tenon joint, it gets a little confusing because there are really TWO mortises involved, one for the tenon and one for the wedge (or wedges),so the one for the wedge(s) is specifically referred to as the "wedge mortise". The JOINT is called a "tusked" joint because a wedged mortise and tenon is a completely different joint but the "tusk" is still usually called a "wedge" because that fits more comfortably with normal English usage. Examples:

wedge tool --- A lathe chisel that is sold by only a couple of manufacturers and should not be considered as being among the "common" or "normal" lathetools. It is just a steel cylinder that is sliced at about 45 degrees to the long axis and provided with a handle on the other end. Supposedly, it serves well for both spindle turning (where it is used to create coves) and for face turning (where it is used for finishing cuts to provide a smooth surface). I've never used one but it looks to me as though it would be a little hard to control on face turnings when using the side as a slicing tool. Examples:

welding --- a method of joining two similar or dissimilar pieces of metal by using a 3rd metallic element or compound which melts at a lower temperature than the other two. If the temperature is below 450 degrees Celcius, then the process is called soldering. If the temperature is above 450 degrees Celcius but below 800 degrees celcius, then the process is called brazing. If the temperature is above 800 degrees Celcius, then the process is called welding, but unlike soldering and brazing, welding actually melts and fuses the two materials in addition to adding a third.

wet --- see sandpaper

wet cooperage --- synonymous with tight cooperage

wet dry --- see sandpaper

wet film thickness --- The thickness of a liquid finishing agent immediately after application, before it begins to dry.

wet processing --- Hardboard is produced by reducing wood to fibers, which gives the name fiberboard. With wet processing, the fibers are suspended in water, then laid out on a mat to dry. This releases the natural resins which bond the fibers together, instead of an artificial bonding agent, although some wet processed boards have additional bonding agents added to give them certain properties. It's generally possible to tell the difference between dry and wet processed hardboard as dry board is typically smooth on both sides. Wet board has one smooth side and one "mesh" side. The mesh finish is a result of water draining out of the mesh side after pressing. One exception is hardboard for furniture which has usually been sanded. This doesn't have a mesh finished side but there's still a noticeable difference as one side is polished and the other side has a matt finish.

wetting --- The extent to which a finishing agent flows onto a surface in order to achieve a good spread over the surface.

wetwood --- Unseasoned wood with an abnormally high moisture content that is generally the result of either infections in living trees by anaerobic bacteria or of water logging when logs are floated to a mill. The condition can occur in both softwoods and hardwoods and the wood is usually exceptionally difficult to dry without defects. Although difficult to recognize, wetwood is often characterized by a translucent, watersoaked appearance and a sour or rancid odor.

wheel and axle --- (1) One of the 6 simple machines of classical mechanics, the wheel and axle is, exactly as the name sounds, a wheel on an axle. It uses the principle of mechanical advantage both to trade distance for force and also to change the direction of a force from rotational to linear or linear to rotational. The simplest example of the use of a wheel and axle is to wrap a rope around the axle turn the wheel to lower and raise a bucket into and out of a well. If the spokes of the wheel are long and the axle has a fairly small diameter, then the force multiplier can be large, allowing a small rotational force on the spoke to cause a large linear force on the rope, although of course the amount of movement of the rotational force will be correspondingly larger than the linear movement of the rope.

wheel lock nut --- synonymous with serrated flange nut

whet --- To sharpen, as on a sharpening stone.

whetstone --- synonymous with sharpening stone

white cooperage --- A form of tight cooperage where the product created is straight sided (such as a butter churn).

white lumber --- lumber that has not been treated in any way other than having been cut from a log.

white rot --- A type of biodegrade caused by certain wood-destroying fungi that attack both cellulose and lignin in wood, producing a spongy and stringy mass that is usually whitish but which may assume various shades of yellow, tan, and light brown. Wood affected by white rot normally does not crack across the grain and will only shrink and collapse when severely degraded. Infested wood will gradually lose its strength and become spongy to the touch. Boards can become severely damaged in 6-12 months, and even faster under hot and moist conditions. It can be found in exterior columns, steps, porches, and decks, as well as in doors, windows, and door and window frames. Occasionally, it occurs in wood trim, rafters, joists, sheathing, siding, sills, joists, and subflooring. Examples:

whole tree chipper --- A machine for reducing whole trees to chips. "Whole tree" means that branches and limbs are still attached, and the machine has to have a feeding mechanism that folds the branches into the feed hopper. Compare/contrast to hammer mill, mill chipper, and tub grinder.

wicking --- In terms of woodworking, this refers to the tendency of wood to draw moisture up through its cells by capillary action in the direction of the grain.

wide belt sander --- This is a large, floor model, power sander with a belt that can range from about 18" wide to several feet wide. There are models that have belts wider than 4' so that they can sand the surface of a standard sized panel; these models are VERY expensive. This is not really a hobbyist's tool but something you would find in a commercial wood shop. These are used with rough grits to do cut down and level a surface and are also used with fine grits to do a finish sanding on a large area. Compare/contrast to other forms of the belt sander. Examples:

wide grained --- synonymous with loose grained

wide swing hinge --- A butt hinge that has one extra wide leaf and is mounted with the barrel offset from the door/frame joint so that the door moves out of line with the frame when opened, thus giving extra clearance. Often used in hospital rooms and some industrial settings, the point being that it provides unobstructed access through the entire width of the door frame. Examples:

need to add wide swing hinge pics

wide throw hinge --- synonymous with wide swing hinge

wild figure --- A somewhat subjective term, referring to irregular markings that make a piece of wood particularly interesting. I think all would agree that a simple piece of flat cut maple with very regular grain lines would never be said to have wild figure, but how about a slightly more interesting than usual piece of zebrawood? Some might say it had wild figure whereas others would not.

wild grain --- synonymous with irregular grain

wimble --- A boring tool, such as a gimlet or auger.

wind bracing --- bracing members required to resist the forces on a structure resulting from wind pressure. See diaphragm, wind post, and collar tie.

winder --- A turning tread in a curved staircase. Winders vary in depth from smaller at the end that is near the center of the curve and larger at the end that is on the outside of the curve. Examples:

windfall --- synonymous with blowdown

winding --- A warped or twisted board is said to be winding or in wind. See also winding sticks.

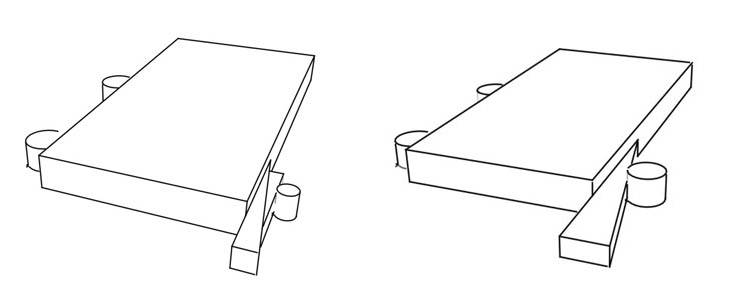

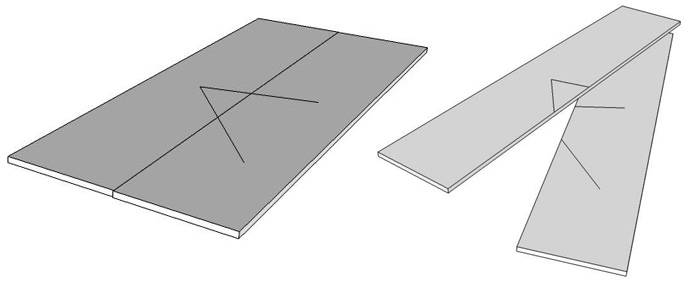

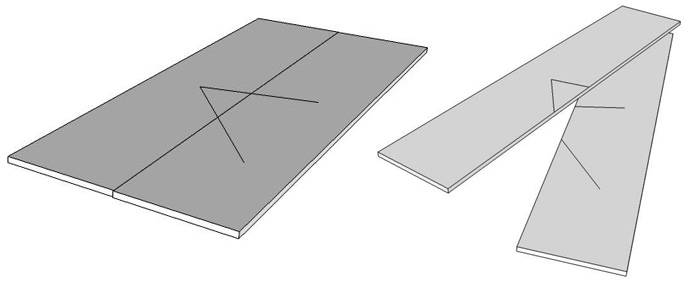

winding sticks --- It is easy to see whether or not a plank has twist when it is significant but for small variations from true, it can be hard to tell. One way to aid this determination is to take two sticks with parallel upper and lower edges and lay one across each end of the plank. You can then sight along the plank's length, over the top edges of the sticks, and their edges line up you know the plank is flat, but even small amounts of twist in the plank can be seen by the top edges of the two sticks not being parallel to each other. The same effect can be achieved by having one end of the plank pressed flat on a bench and checking to see if the other end is also flat on the bench or twisted up on one side. Also called winding strips.

winding strips --- synonymous with winding sticks

window seat --- A bench built in just inside a bay window. Window seats sometimes have hinged seats so that the area under the seat can be used for storage (it's great for kids toys, but can obviously be used for most anything). Examples:

wind post --- A structural column that stiffens a framed wall against wind loads.

windthrow --- synonymous with blowdown

winged bowl --- there are two types of bowls that are called "winged". The first is a bowl with "wings" that flow from the upper rim back downwards. Such drooping drooping wings may stop short of the bottom of the bowl or they may go down so far that the bowl is supported by the tips of the wings rather than the bottom of the cavity part of the bowl and when this is the case, the bowl is called a "lifted bowl" or "raised bowl" although I've almost never seen those names used. The second type is a bowl with a flat portion extending out from the top, or just below the top, of the bowl. This is often done with burls, where the natural edge of the burl is kept at the outer rim of the flat part. "winged bowls" are sometimes tuned in a way that allows them to be given tops, in which case they are called "winged boxes". Compare/contrast to other lathe turnings. Examples:

winged bowls type 1

winged bowls type 2

winged box --- A box with "wings" that flow from the upper rim back downwards, or sometimes straight out. Downward drooping wings may stop short of the bottom of the box or they may go down so far that the box is supported by the tips of the wings rather than the bottom of the cavity part of the box and when this is the case, the box is called a "lifted box"? or "raised box"? or something like that (I need some help here) and the "box" is often turned with an underside that is more round that would be the case on a normal "box". Compare/contrast to other lathe turnings. Examples:

wing nut --- A nut that has "wings" (upsweeping flanges) on the sides so that it can be turned with fingers instead of needing any kind of wrench or pliers. See also thumb screw and wing screw. Examples:

wing screw --- Exactly what you would have if you took a wing nut (which is much more familiar to most people) and super-glued it to the end of a threaded rod. It's a bolt (NOT a screw) that has a "wing nut like" head, although the term is sometimes used to describe items that should be called thumb screws. Examples:

WIP --- Work In Progress

wipe --- [noun] A rag of any sort used for shop cleanup

wipe --- [verb] An application technique for putting finishing agents onto wood. Wiping is often preferred over brushing because it is better at working the finishing agent into the wood and also it is less prone to air bubbles. Wiping is the only suitable application technique for wax finishes.

wiping stain --- A stain applied to bare wood with the excess being wiped off before it dries. Often used to give a desired color to wood and then covered by a more permanent finishing agent.

wire brush --- A brush with wire for the bristles (in place of hair, straw, or plastic). Used in woodworking for cleaning various metal surfaces (e.g. rusted bar clamps), cleaning off old coats of finishing agents, and also for distressing wood surfaces. There are many forms, including circular ones for use in bench grinders, drill presses, hand drills, Dremel tools, and so forth. There is a particular form used for cleaning out the grooves in files and that's the file card. They can be had with both steel and brass bristles. Examples:

wire edge --- see burr

wire nail --- A nail that starts out as a length cut from a strand of wire. This can be any of several types of nail. Common nails, box nails, and brads are all usually wire nails, including even the larger sizes, because automated construction techniques make very effective use of wire.

wire nut --- A simple but incredibly useful device that rivals the paper clip in ingenuity, this is a plastic cone with a spiral of conductive wire inside; you jam two stripped electrical wires into it and then you twist it and the wires are physically (and therefore electrically) mated with a strong bond that can be released later by just reverse-twisting the cap. It does have the drawback that a lot of vibration can loosen the connection, so there are applications where it is still better to rely on a soldering iron and/or electrical tape. Examples:

wire wool --- synonymous with steel wool

with the grain --- The direction parallel to the length of the longitudinal elements (fibers and/or vessels) of wood.

witness mark --- A mark put on objects that are destined to be joined together in a final assembly but which have to be kept separate for a while for individual work. The marks show how the pieces go back together and they can then be separated and worked on and then accurately lined up again for final assembly. Example:

wobble --- (1) In general, this refers to any undulating movement of a tool or part of a tool. For a circular saw blade, it refers to the amount of left-to-right movement that the cutting edge makes during operation. This can be due to slight warping in the blade or just because of lack of stiffness in the blade. Also called runout (although that term has another more commonly used meaning).

wobbly head dado cutter --- synonymous with adjustable dado blade

wolf tree --- A logging term meaning a large older tree with a spreading crown and little or no timber value, but often great value for wildlife.

wood banding --- see banding definition 2

wood burn --- The darkening of wood surface due to severe heat caused by a rotating cutter such as a circular saw blade or a router bit. This is the sign of either improper technique or a dull cutting edge.

wood carving --- One of the oldest of human art forms, carving figures in wood goes back to pre-history, although samples have not withstood time as well as cave paintings and stone sculpture. It includes both full object carving, representational or otherwise, and also the decoration of larger wooden objects such as religious alters and furniture by using gouges and chisels to shape the wood surface.

wood filler --- see filler and wood putty

wood flour --- Extremely fine wood chips with a consistency roughly that of sand although chips can range in size up to about that of a grain of rice. High quality wood flour is made from hardwoods for chip size consistency but low grade wood flour is sometimes made from softwoods. Wood flour is commonly used as a filler in thermosetting resins such as Bakelite and also in Linoleum. It is also used in other compositematerial products.

wood foundation --- see permanent wood foundation

woodland --- see forest

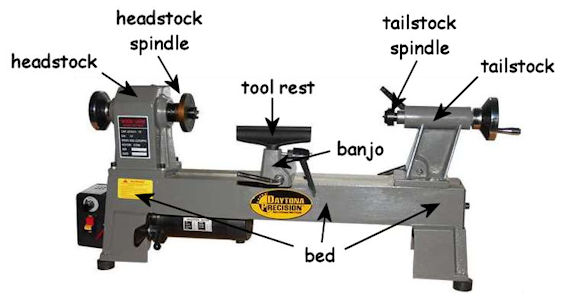

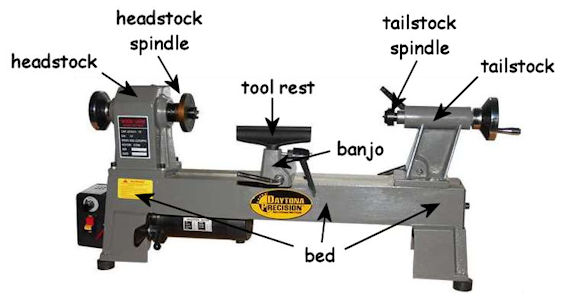

wood lathe --- A machine for shaping wood by rotating it rapidly along its axis while using very hard, sharp-edged gouges, chisels, or scrapers to shape the rotating surface. In woodworking, lathes are used to create table legs, spindles, bowls and so forth, and then there are huge lathes that are used to slice certain types of veneer including rotary cut veneer and thick softwood veneer for plywood. The illustration below shows some of the major parts of a typical wood-turning lathe. The distance from the headstock to the tailstock determines how long a piece can be mounted and turned to create a spindle-shaped object, and the distance from the centerline of the headsotck/tailstock down to the nearest point on the bed determines the radius of the largest object that can be turned in face plate turning. Since it gives a bigger number, and vendors always like bigger numbers, the diameter of such an object is normally quoted, rather than the radius, and this is called the swing of the lathe. In other words, a spec sheet for a wood lathe won't directly tell you the distance from the head/tail centers down to the bed but rather will tell you how much twice that amount is. Wood lathes have a rotatable tool rest that sits on top of a sliding banjo and the combination of moveability thus provided allows the lathe tool to be position anywhere that is needed such that the cutting edge does not hang too far over the tool rest (if the tool hangs too far over the tool rest, then the leverage is very poor and a strong catch can either break or bend the tool, or grab it out of the operator's hand). Example, with parts labeled:

wood on wood --- synonymous with two ply veneer

wood preservation --- see preservative

wood putty --- [aka wood filler and plastic wood] A substance, usually doughy or clay-like, used to fill imperfections, nail holes, screw holes, and sometimes just the open pores, of wood prior to putting on the first coat of finishing agent, so as to allow the wood to achieve a smooth finish and not show any kind of dents or depressions.

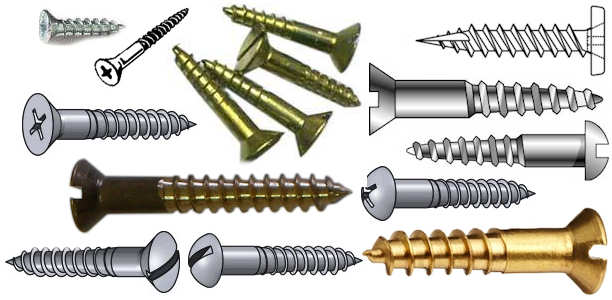

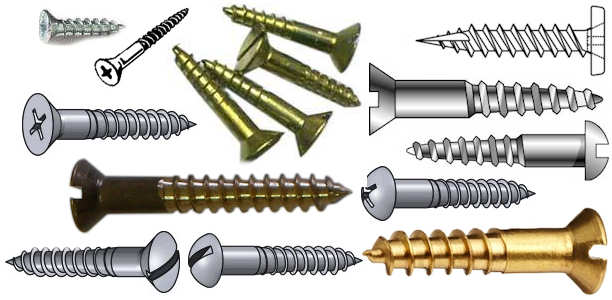

wood screw --- A screw designed for wood or a similar material, with a pointed, tapered shank, relatively coarse threads, and sometimes an unthreaded portion just under the head. Wood screws are designed to fasten objects to wood or to fasten two pieces of wood together. The pointed shaft is often driven directly into wood, but depending on the hardness of the wood, a pilot hole may be required. There are a huge number of different head styles and drive types and other characteristics of fasteners that may have other specific names but are also what is meant by the term "wood screw", including many that do NOT have a tapered shank but rather have a straight, threaded, shank with a pointed end. Materials include steel, brass, and aluminum. See also bolts vs screws. Compare/contrast to machine screw. Examples:

wood sealer --- see sealer

wood stabilizer --- Any one of various chemical compounds that have one of two functions: (1) To treat rotten wood so that it will not go any further in the decay process and (2) to fill green wood with a chemical that will reduce the effects of drying so that the wood can be used immediately. Turners can turn green wood bowls with the use of the 2nd type. With the first type, it is usually necessary to also use a filler in addition to the stabilizer because while the stabilizer keeps the wood from rotting any further, it does not fill in any voids already created by the rot and depending on the particular type of stabilizer, it may or may not harden the wood in addition to stabilizing it.

wood tar --- see tar

wood turning --- The process of using a wood lathe to create an object which is symmetrical around a vertical axis. There are two basic types of wood turning, face turning and spindle turning.

woodworking bench vise --- A vise that is permanently mounted under a workbench beneath the level of the top of the bench. These are usually put at one end of a workbench and they are often supplemented by some sort of holding mechanism at the other end of the bench so that a plank can be put in the vise jaws and supported along its length by the support at the other end of the table. Also, because they sit below the level of the bench top, they usually have a small pull-up tab, called a vise dog, that allows them to clamp against workpieces that are flat on the top of the bench. They use a lead screw mechanism and most also have a quick release mechanism (based on a split nut) on the lead screw. Compare/contrast to the machinists bench vise. Examples:

wooly --- as regards woodworking, this is the same as fuzzy.

workability --- The ease with which a wood can be worked by hand or machine tools of any kind. Although somewhat vague and ambiguous, this is a standard "measure" that is always given along with any serious discussion of the properties of a wood species.

worked lumber --- lumber that has been surfaced and may also have been matched, shiplapped or patterned.

working life --- synonymous with working time

working time --- (1) The length of time after an adhesive is spread before it becomes unworkable or loses its ability to create a bond and (2) The length of time a finishing agent remains usable after the original package is opened or a catalyst or other curing agent is added. Also called "working life" and "open time". Working time varies depending on temperature, the type of adhesive or finishing agent, relative humidity, and other factors. Often used when referring to two-part epoxy and polyester glues. A similar term is pot life but pot life carries a definite connotation of things having been mixed, whereas working time can refer to an opened can of paint where no mixing of ingredients (just stirring) has taken place.Use the following times as rough guidelines for adhesives:

- aliphatic resin (yellow) -- 5-10 min.

- polyvinyl acetate (white) -- 10-15 min.

- water-resistant (yellow) -- 5-10 min.

- polyurethane -- 20 min.

- epoxy -- 5 min.-12 hrs. (varies greatly by type)

- liquid hide glue -- 10 min.

workpiece --- The object being cut, clamped, sawed, drilled, routed, turned, gouged, sanded, painted, or otherwise screwed around with; the thing being worked on.

worm drive saw --- A hand-held circular saw but with geared motor behind blade instead of directly on the blade arbor. The conversion of the motor motion to the blade is done via a worm gear, thus the name. Worm drive saws turn more slowly but more powerfully, making them a preferred choice for professionals because (1) they provide more clearance around the blade in front (thus making it easier to see where the blade is relative to the cut line) and (2) they more easily go through difficult material. The "normal" circular saw is the choice of most hobbiests because of the lighter weight and high-speed blade.

worm hole --- A hole in wood caused by the burrowing action of wood-infesting worms and insects and their larvae. See wormy for further discussion.

worm tracks --- synonymous with insect engravings

wormy --- Having worm tracks or holes. This is a form of defect or character (depending on how you look at it) in wood where there are numerous spots and/or channels throughout the wood where it has been eaten away by various boring agents including insects, insect larvae, and worms. Sometimes the eaten away area is filled in so that there are no voids but just discolored areas. Usually such areas are punky. This is usually in the form of elongated worm-shaped areas, but may also occur as spots (much like pecky) depending on the cut of the wood and other factors. NOTE: worm holes are quite common in wood and the presence of a few worm holes does not generally trigger the designation "wormy" which, as I said at the beginning of this paragraph, is usually reserved for wood with NUMEROUS worm holes. HOWEVER, not all wood vendors agree with or follow what I just said, so you may find "wormy" wood that doesn't have many worm holes. In most trees, wormholes are far more likely in the sapwood than in the heartwood. At least one form of worm hole (and the surrounding discoloration), called ambrosia is considered a favorable characteristic and is highly favored by bowl turners. Below is composite pic showing wormy chestnut veneer, spruce with heavy worm tunnels, and the end grain of an ash plank showing both holes and tracks, plus the punky material that is sometimes left in wormholes. To see more examples of wormy wood, click here: wormy wood pics.

woven valley --- A method of installing shingles in a valley by laying one shingle over the other up the center of the valley. Compare/contrast to closed cut valley and open valley.

wrap around hinge --- A type of hinge that either partially or fully wraps around both the edge of a frame and the matching door. The two types are shown in this glossary at:

wrench --- A tool used to provide a mechanical advantage in applying torque to turn bolts, nuts, pipes and other objects by either grabbing them or by mating against flat surfaces on their rims. There are a great many types of wrenches for various, sometimes highly specialized, uses. In woodworking, the most common types are the crescent wrench and the box wrench. Wrenches differ from pliers in that pliers are primarily for increasing compression leverage (that is, squeezing in) whereas wrenches are for increasing rotational leverage and may not do any squeezing at all. Pliers can sometimes be used to do the job of a wrench but wrenches generally will never do the job of pliers. Types of wrenches most likely to be seen by woodworkers include:

- adjustable wrench --- same as crescent wrench

- Allen wrench --- a hex-drive device

- box wrench --- a ring with internal indentations for gripping a nut

- combination wrench --- has a crescent or ring on one end and a box wrench on the other end

- crescent wrench --- has a pair of prongs with one of them adjustable

- monkey wrench --- can mean a crescent wrench but most often means a pipe wrench

- open ended wrench --- has two parallel prongs that fit around a nut or bolt

- pipe wrench --- heavy duty adjustable wrench

- plumber's wrench --- same as pipe wrench

- ratchet wrench --- same as socket wrench, box wrench, or combination wrench, when they have a ratchet mechanism. action

- ring wrench --- same as box wrench

- socket wrench --- interchangeable head form of box wrench

- torque wrench --- measures and/or limits the amount of torque applied to nut

- NOTE: there are many other forms of specialized wrenchs (e.g. spark plug wrench, impact wrench, etc) not used for woodworking and so not listed here.

WTC --- Whole Tree Chips [or Cchipper] --- see whole tree chipper.

X-acto knife --- This is a razor blade-like piece of steel in a handle, very handy for fine work and in use for general craft work since before World War II. The blades come in various sizes and shapes including flat, angled, curved, etc. Prior to digital image manipulation, such knives were widely used in doing cut-and-paste work for composite images. The image below shows is the "standard" blade. The knurled section twists to unlock the collet and allow easy blade changes.

xylem --- The cellular tissue inside a tree's bark, including both heartwood and sapwood; in other words, xylem is a scientific name for what we normally just call "wood".

yacht varnish --- An exterior-grade varnish especially suitable for salt-water climates.

yard --- (1) A place where wood products are stored and/or made available for sale. More commonly called a "lumber yard" if it's a place where wood is for sale.

yard --- (2) A measure of concrete that is one cubic yard (27 cubic feet).

yarding --- The movement of logs from the place they are felled to a landing area for stacking or storage and from which they will be transported to wherever they go next (typically a sawmill).

yard lumber --- A somewhat archaic and little used term designating lumber of all sizes and patterns that is intended for general building purposes. It is generally understood that yard lumber has no special or limiting characteristics other than that it is suitable for general construction. Usually softwood. Compare/contrast to factory and shop lumber and structural lumber.

yardstick --- A three-foot (one yard) long ruler, normally made of wood.

yield --- The proportion of a log converted into lumber. The rest of the log is rarely wasted, but since lumber is by far the most valuable product of a tree, that's what gets counted as the yield. The amount will depend on the type of cut (through and through cuts produce the greatest yield and true quartersawn cuts produce by far the least). Other factors are the thickness of lumber being cut, the skill of the sawyer, the type of saw (the size of the kerf), and whether or not it is dimension lumber.

young wood --- synonymous with juvenile wood

Zahn cup --- A widely used brand of viscosity cup used to measure the flow rate of finishing agents. It is a metal cup with a hole in the bottom and one measures the time required for a given volume of liquid to flow out through the hole. Examples:

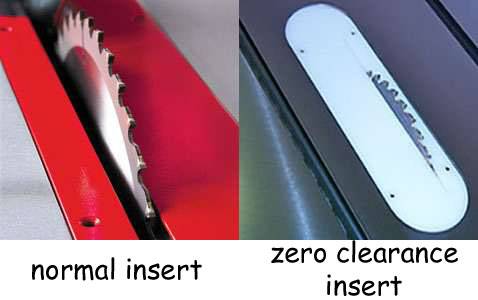

zero clearance hinge --- Although technically this term is properly applied to any hinge that allows unobstructed access for pullout shelves or drawers once a cabinet door is opened to 90 degrees or more, it is usually applied to a specific style of hinge that is also called a European hinge. The point is just to make sure that the door will not protrude into the area of the cabinet opening when open so that any drawer or shelf that is being pulled out through the opening will not be obstructed by the back edge of the door. With the proper mounting in the right kind of door setup, a butt hinge could serve this function, as could a wrap around hinge and others, most particularly the 270 degree hinge. Another, less used, name for these is "zero protrusion hinge". The examples shown here are all of the European hinge type: