The HobbitHouse Ilustrated Glossary of Woodworking terms

JOINERY TERMS

This set of terms having to do with joints and joinery is extracted from the general glossary shown here: GLOSSARY

and links that are not local to this subset will put you back in the main glossary

for images of wood itself, go here: wood id site

adhesive joint --- (1) A joint that uses an adhesive instead of nails or screws. Compare/contrast to dry joint. In normal use, this term is used as synonymous with glue joint (a more-often used term) even if the adhesive is not glue.

adhesive joint --- (2) The location at which two objects are held together with a layer of adhesive.

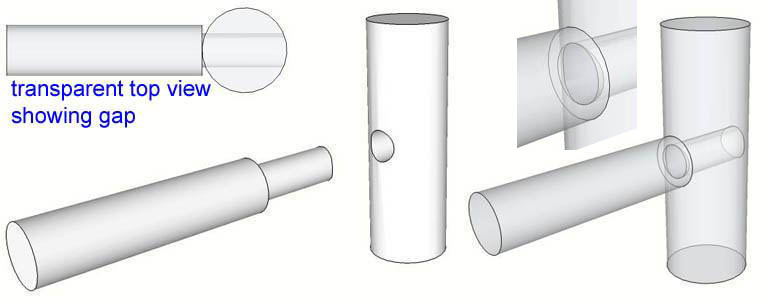

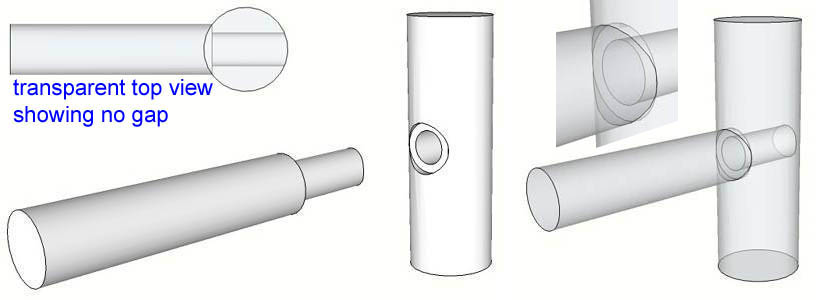

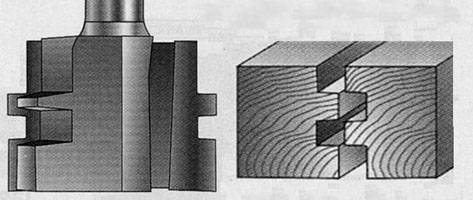

adjustable dado blade --- The dado is one of the simplest and most widely used joints in woodworking and since it cannot be made with a single pass of a normal circular saw blade, special dado cutter blades have been developed. There are two fundamental types, the adjustable dado blade which is discussed here and the stacked head dado cutter which is discussed as its own term in this glossary. The adjustable dado blade is a slightly complicated device which consists of a circular saw blade that has an adjustable angle so that it wobbles by an adjustable amount and thus cuts a dado groove of whatever width is set; sometimes there is more than one blade, but the adjustable wobble is always part of the mechanism. This is a somewhat sloppy solution because it does not produce perfectly vertical groove walls nor does it produce a perfectly flat groove bottom although neither are off by any significant amount. There is one version, shown in the far left in the composite pic below, that is actually more like a stacked head dado with chippers plus adjustable shims so that it does not suffer the disadvantages of the more common adjustable dado blades. Also called a "wobbly head" dado cutter. Examples:

anchor piece --- When two pieces of wood are joined with a screw, the screw goes through one piece, which is called the "captive piece" and into the other, which is called the "anchor piece".

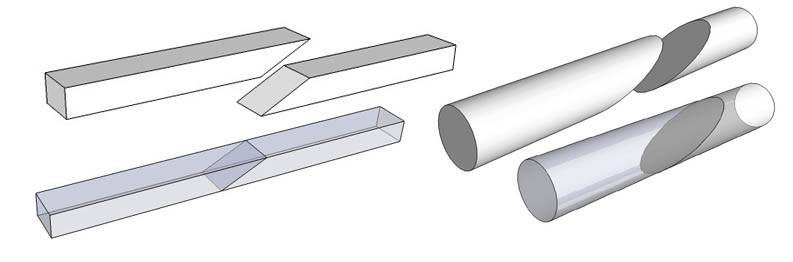

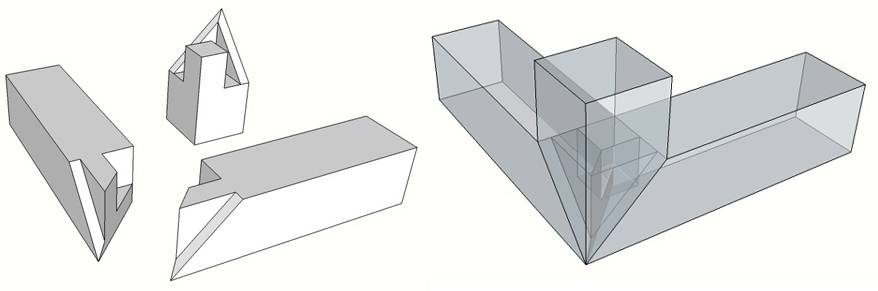

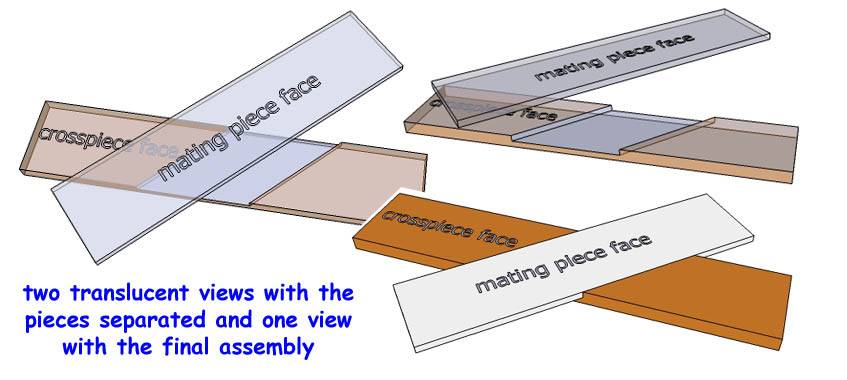

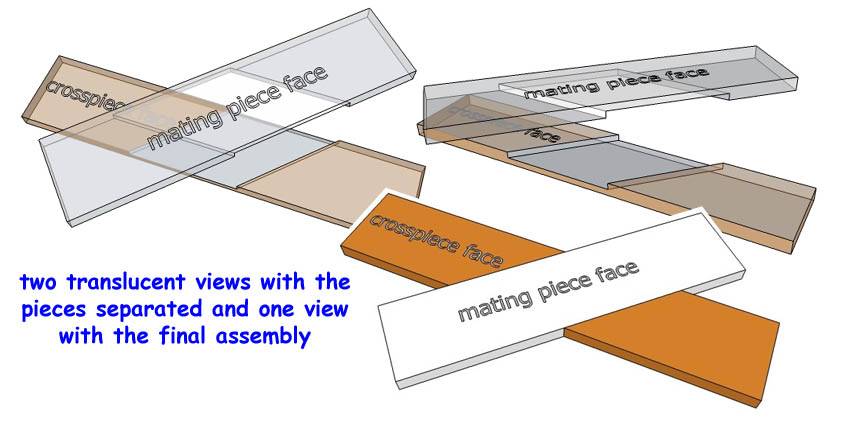

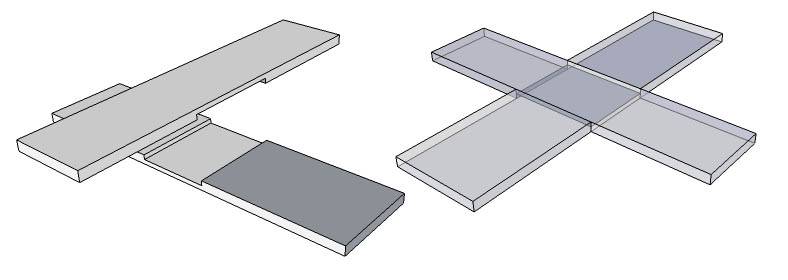

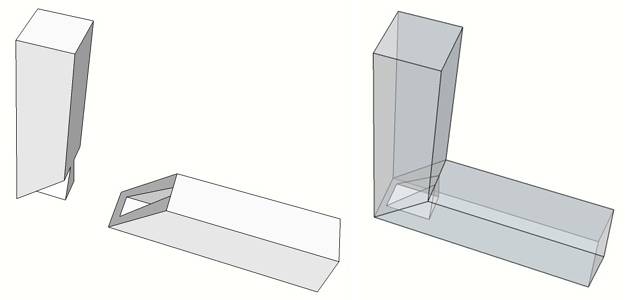

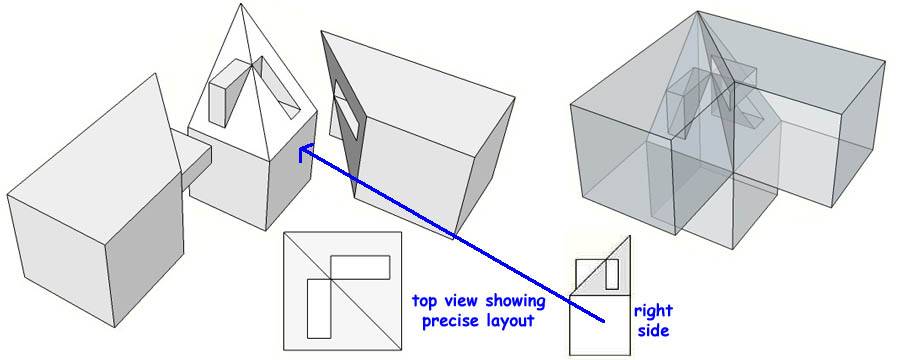

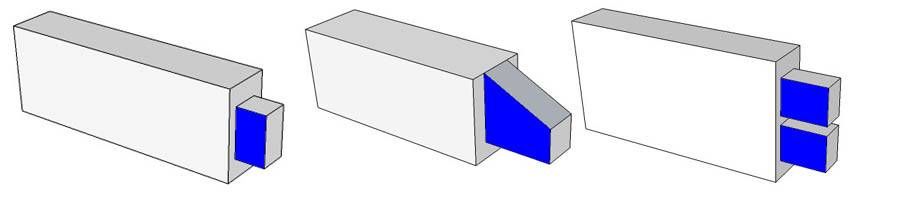

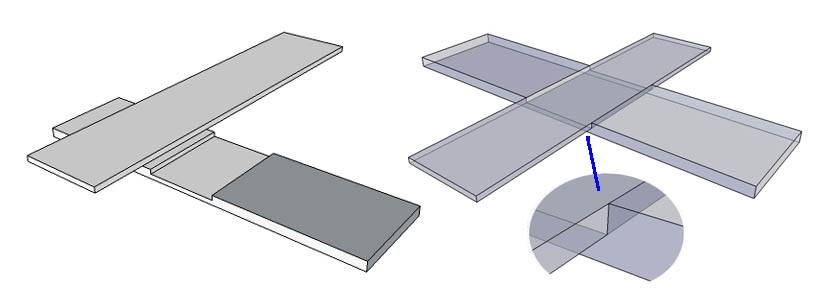

angled crossed full lap --- A full lap joint where the two planks meet at an angle other than 90 degrees and fully cross each other. Examples:

angled crossed half lap --- A half lap joint where the two planks meet at an angle other than 90 degrees and fully cross each other. Examples:

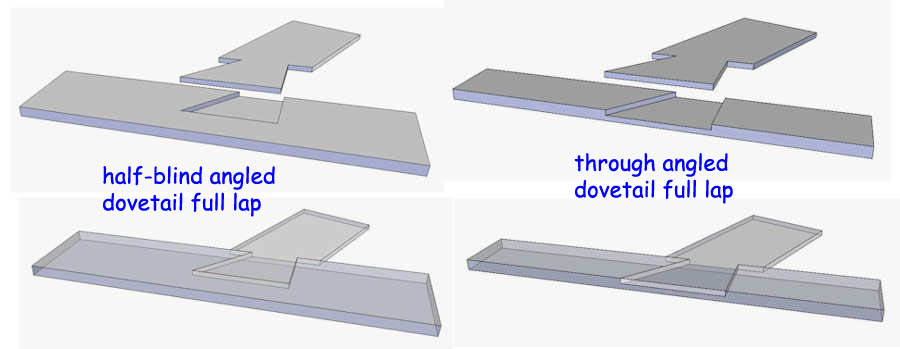

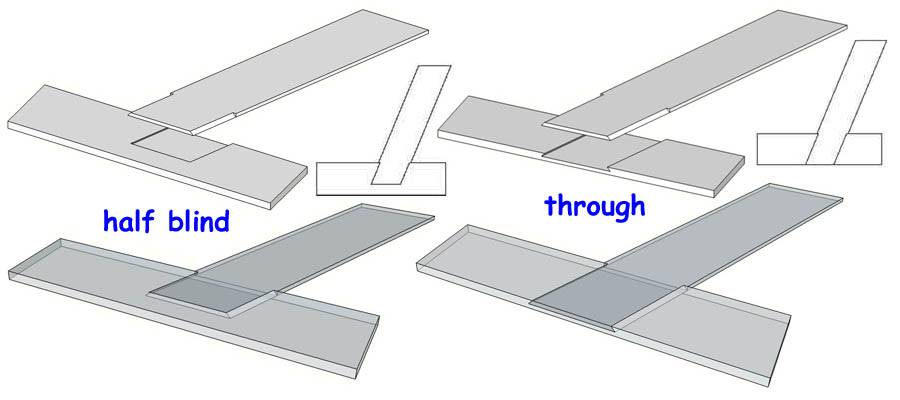

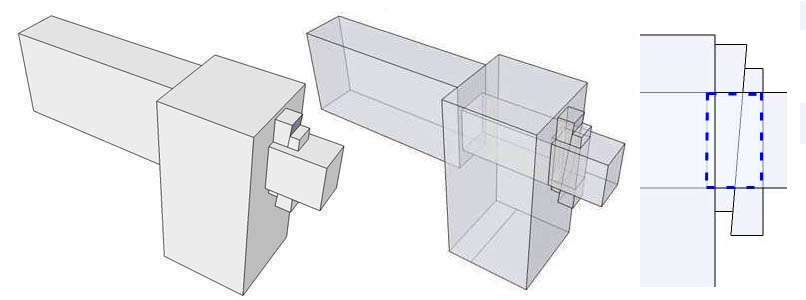

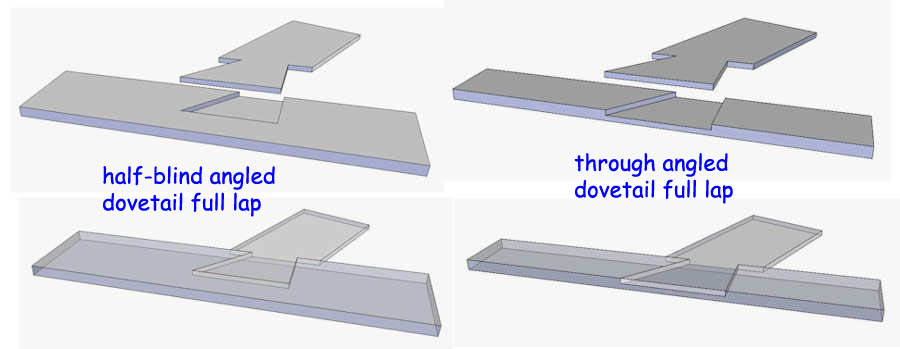

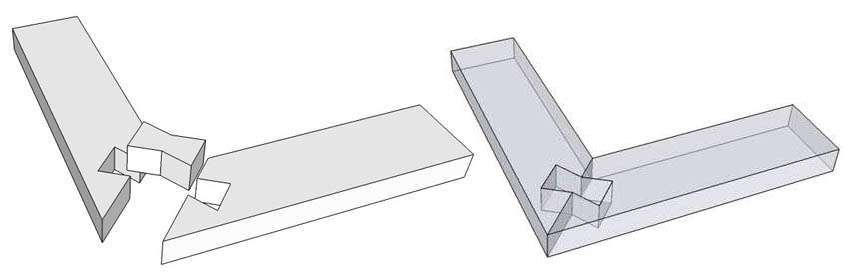

angled dovetailed full lap --- A dovetailed full lap joint where the mating piece comes into the cross piece at an angle other than 90 degrees. As shown in the examples below, the joint can be either half blind or through. Examples:

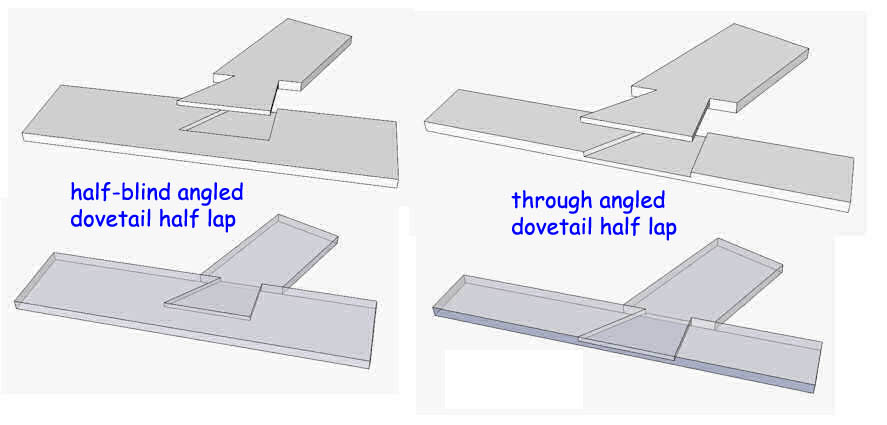

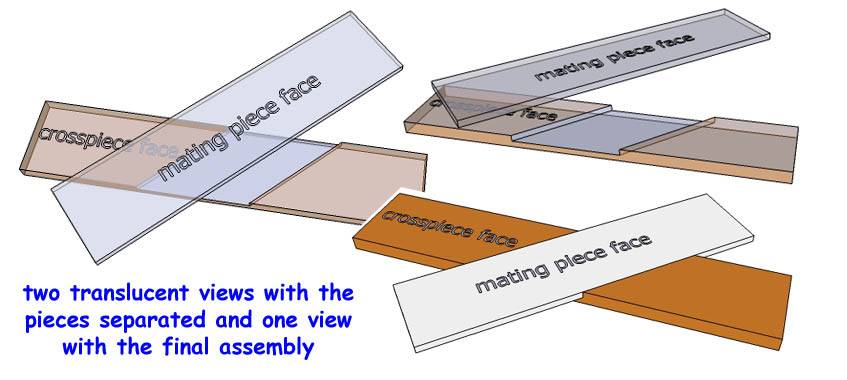

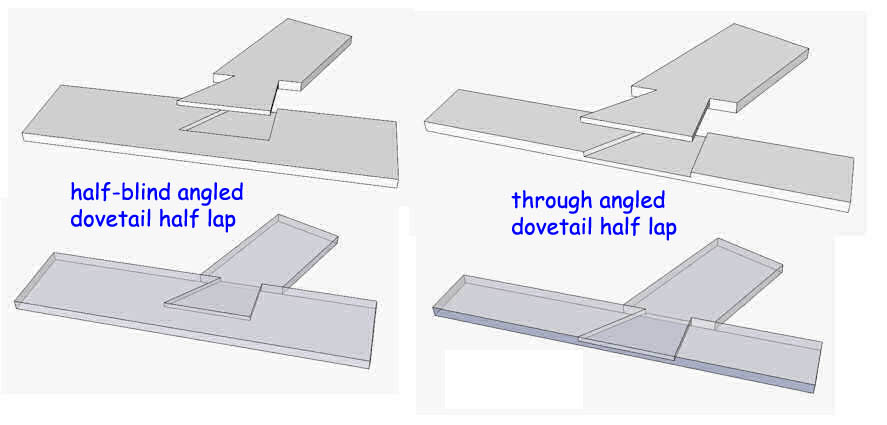

angled dovetailed half lap --- A dovetailed half lap joint where the mating piece comes into the cross piece at an angle other than 90 degrees. As shown in the examples below, the joint can be either half blind or through. Examples:

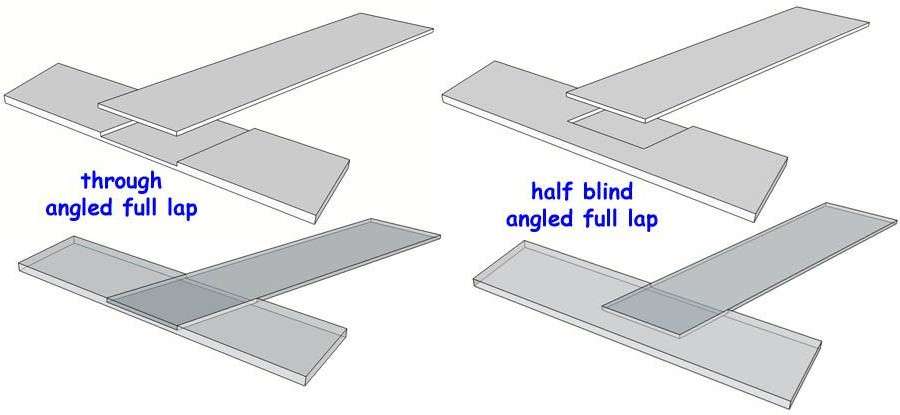

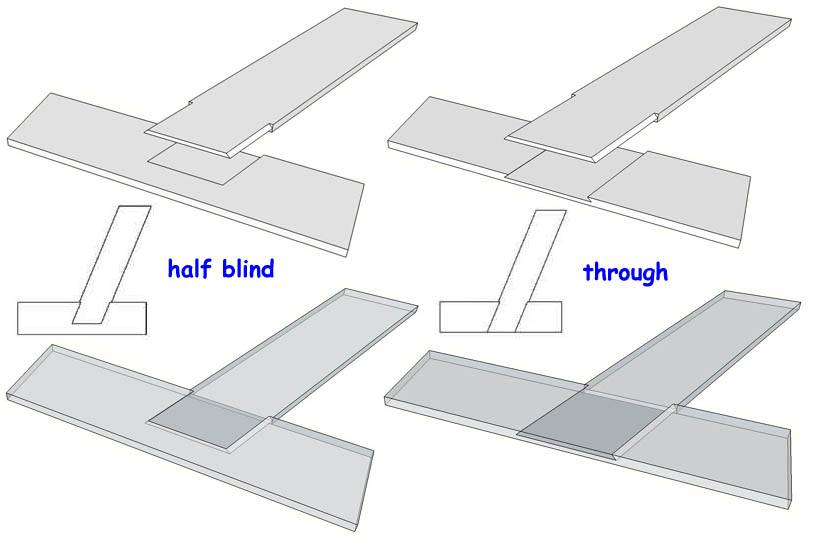

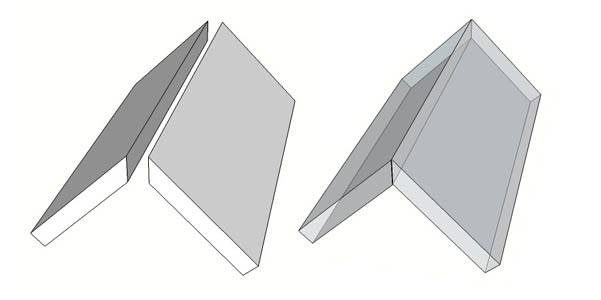

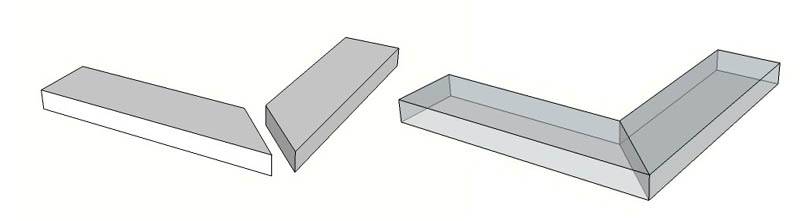

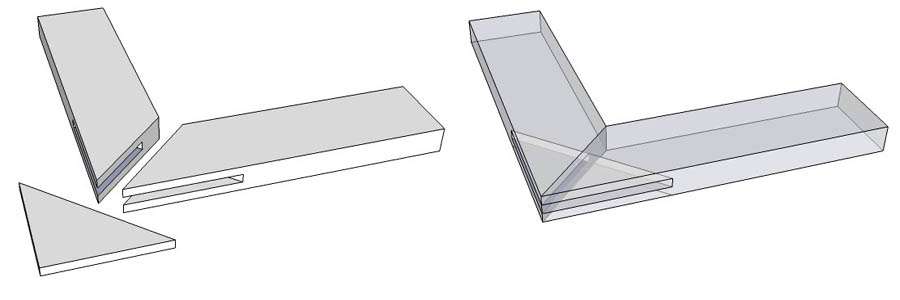

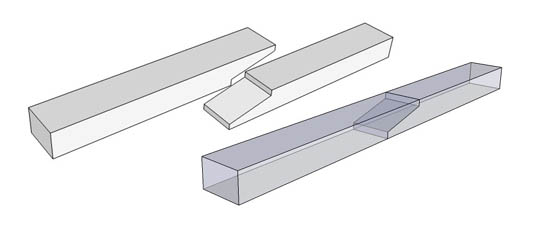

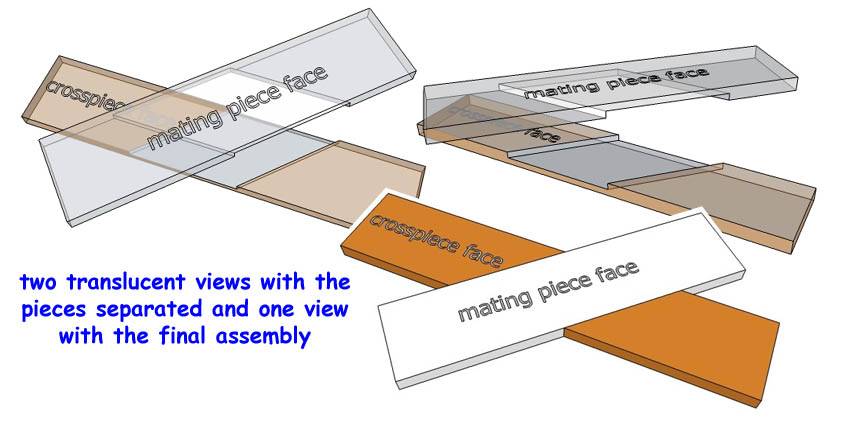

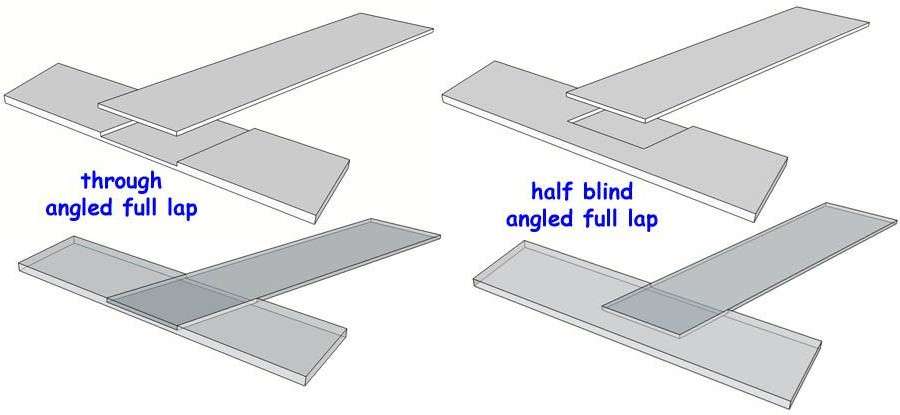

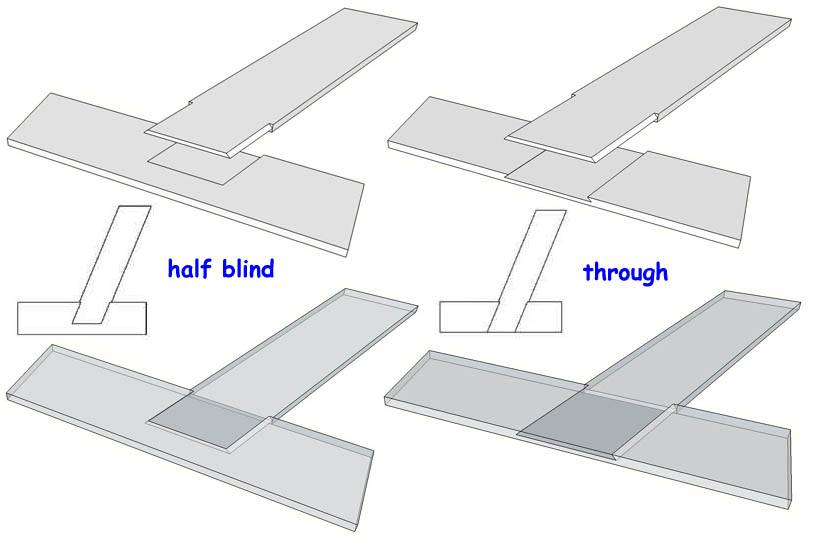

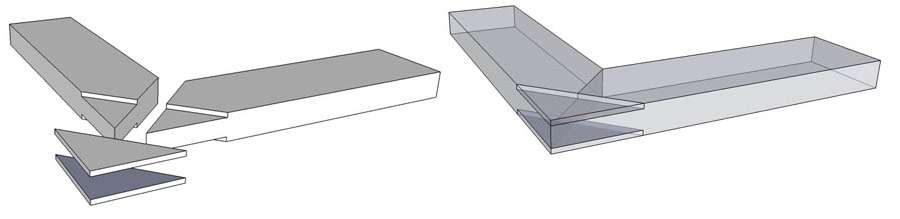

angled full lap --- A full lap joint where the pieces meet at an angle other than 90 degrees. As can be seen in the examples below, the joint can be half blind or through. Examples:

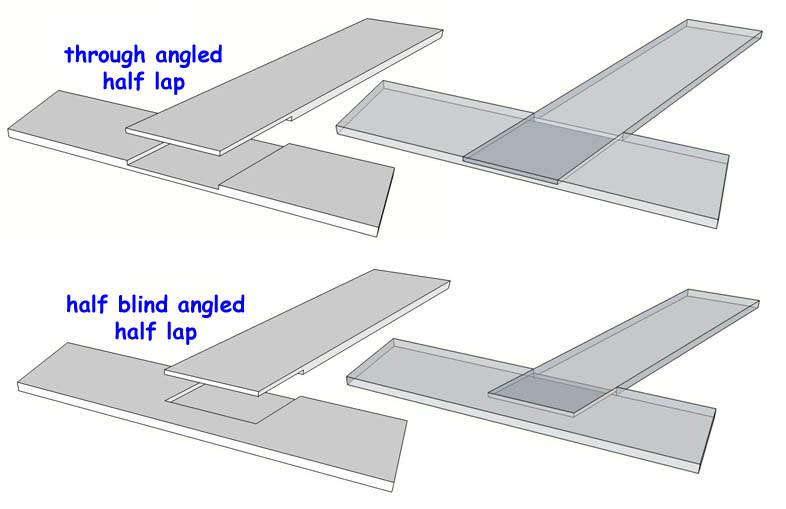

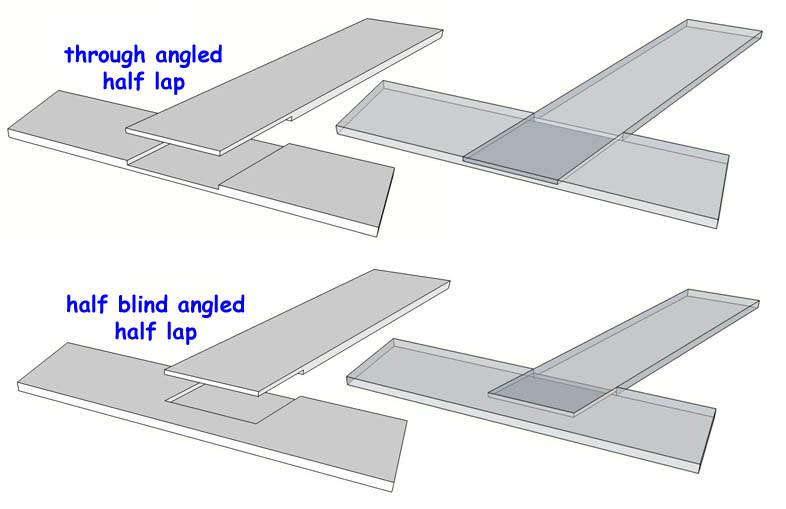

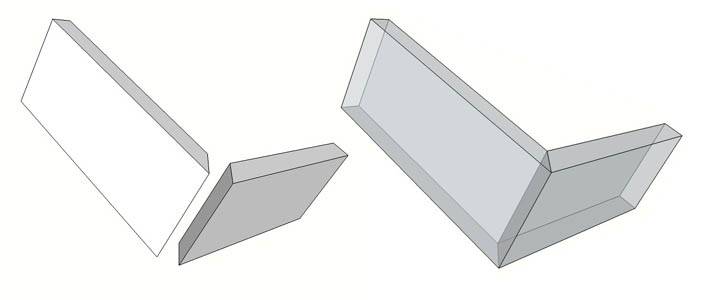

angled half lap --- A half lap joint where the pieces meet at an angle other than 90 degrees. As can be seen in the examples below, the joint can be half blind or through. Examples:

angled keyed dovetail full lap --- A keyed dovetail full lap joint where the mating planks meet each other at an angle other than 90 degrees. As can be seen in the examples below, the joint can be half blind or through. Compare/contrast to angled dovetail full lap. Examples:

angled keyed dovetail half lap --- A keyed dovetail half lap joint where the mating planks meet each other at an angle other than 90 degrees. As can be seen in the examples below, the joint can be half blind or through. Compare/contrast to angled dovetail half lap. Examples:

angled mortise and tenon --- A mortise and tenon joint that uses an angled tenon. See "angled tenon" for an illustration.

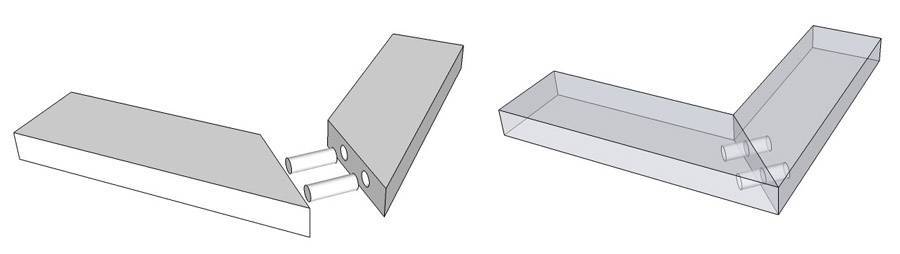

angled shoulder mortise and tenon --- A frame joint but with the two planks meeting at an obtuse angle, and a type of mortise and tenon joining the two. The joint can be done with a loose tenon as in the example below, or with a standard tenon coming off of the upper piece but complicated somewhat because of the angles involved. Such a joint could be used to make a picture frame shaped like a parallelogram, but a more likely example would be joining a banister with a newel post. Example:

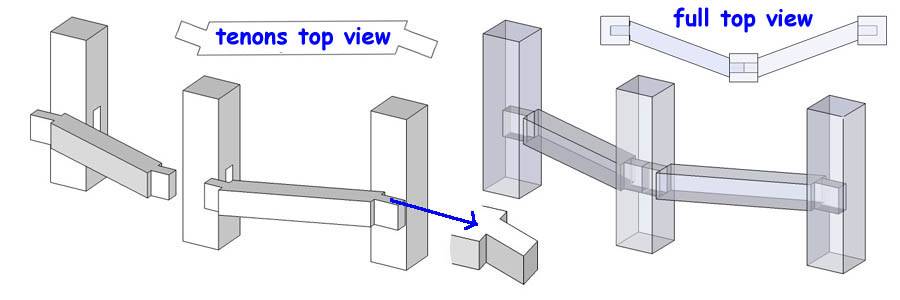

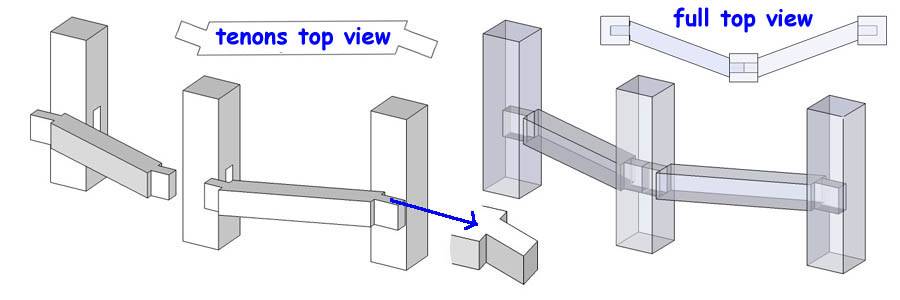

angled tenon --- A tenon that projects out from the surrounding piece at an angle other than 90 degrees. Such tenons are used in a normal mortise and I have never seen reference to a joint where the mortise is angled. Certainly, you could make such a joint but apparently it is either non-existent or so rare that it is not discussed in joinery books. See also mortise and tenon joint. In the example below, the three posts are all 3" square and the stub tenons to the outer posts are 2" long but the tenons to the middle post are each 1.5" long and meet in the middle.

barefaced --- Describes a joint that has only one shoulder, such as the single shouldered sliding dovetail joint.

beaded inset face frame door --- see face frame door

bevel --- (1)[noun] The part of a tool which is ground to form the cutting edge.

bevel --- (2)[noun] A surface that meets another at an angle other that a right angle. See also chamfer

bevel --- (3)[verb] To cut edges or ends at an angle, but not a right angle. See also chamfer.

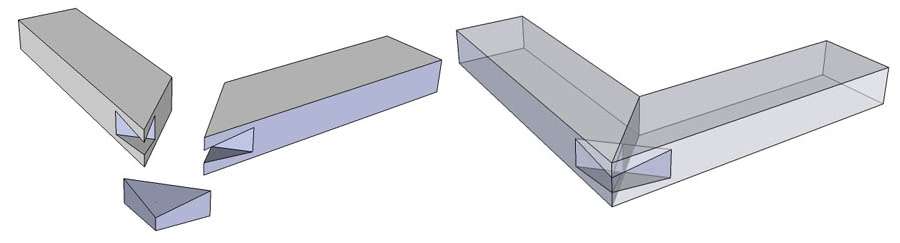

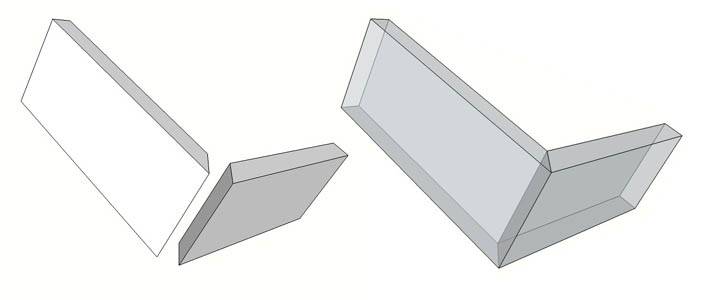

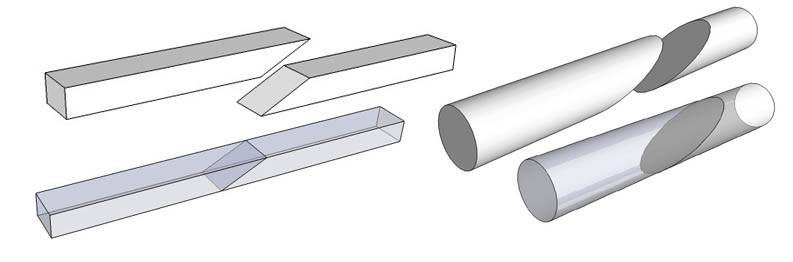

beveled lap scarf --- A lap scarf joint that has the added complication of the laps being angled like half-dovetails. I don't see that this joint really provides much extra strength over a standard lap scarf, unless the planks are constrained from moving up and down relative to each other in which case the dovetail nature of the beveled lap would have a good effect. Examples:

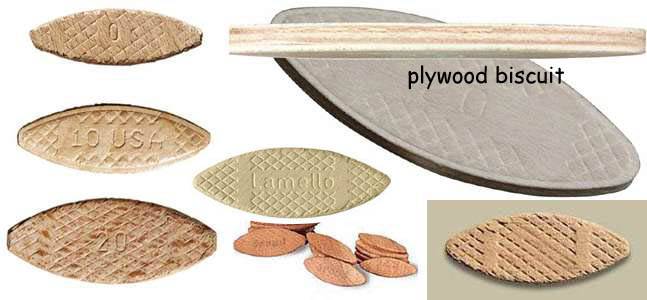

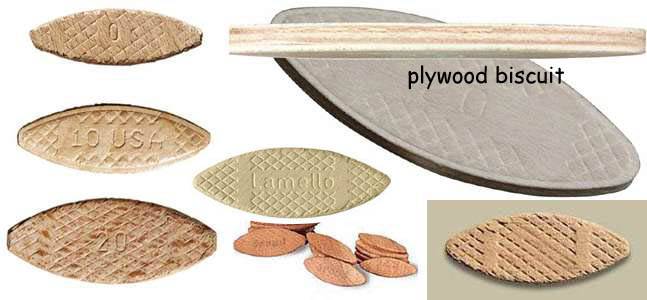

biscuit --- The flat oval wafer used in a biscuit jointer (their use is discussed there). These are usually made from pressed beech, but there are other materials available including plywood. There are three standard sizes, #0 which is 5/8" wide by 1 3/4" long, #10 which is 3/4" wide by 2 1/8" long, and #20 which is 1" wide and 2 3/8" long. The "official" sizes are expressed in metric units because the device was invented in Europe and you will occasionally see non-metric sizes that vary just slightly from those just given. Examples:

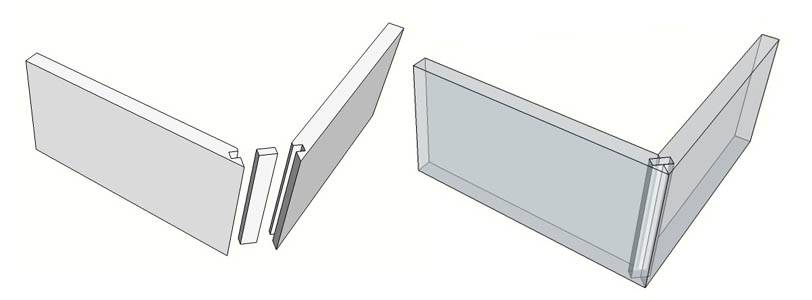

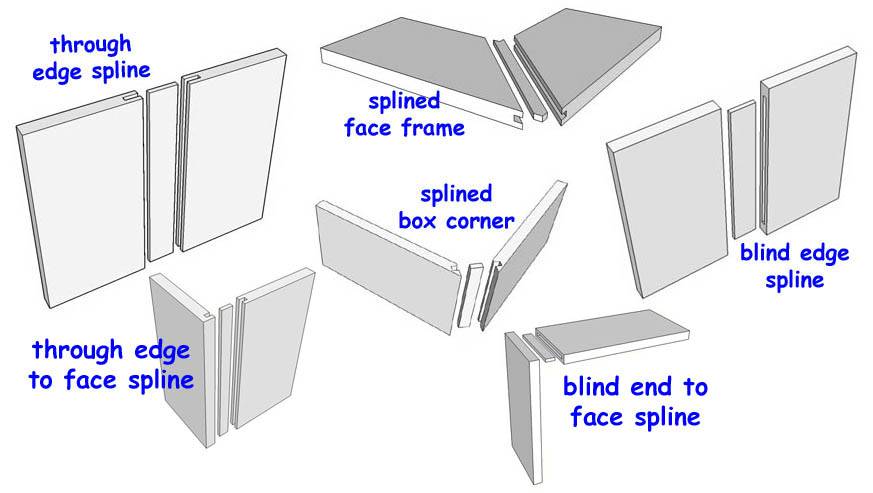

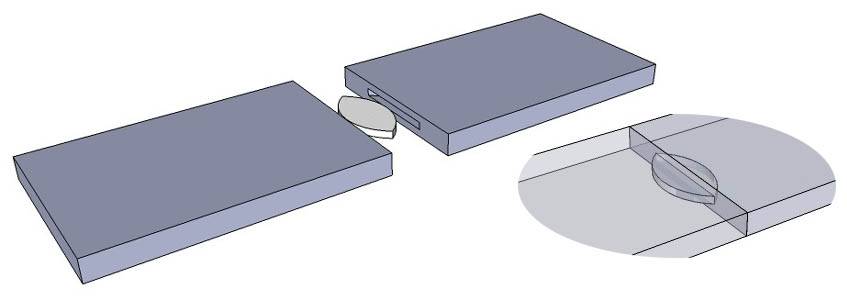

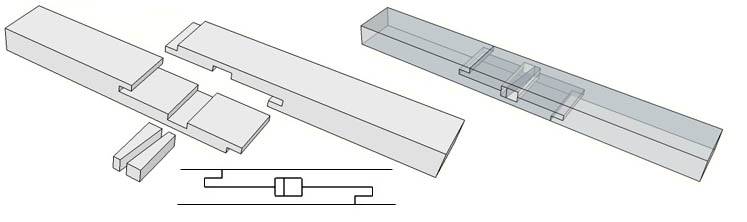

biscuit joiner --- One of the two major innovations in woodworking in the last 20 years (the other being the compound miter saw), this tool cuts oval slots in the edges or face of a board such that mating slots can be filled with glue and a flat oval wafer (called a biscuit and usually made of pressed beech, but also available in other materials including plywood). It was invented in Europe sometime around WWII but only came into widespread use in the last 20 years or less. The wafers expand slightly due to the moisture in the glue and the whole thing makes for a nice tight joint with good shear strength, much like a spline joint and because the slots never have to show at the edges of a workpiece, such joints always have the decorative advantages of blind joints. The biscuits come in three standard sizes and the tool is available in battery powered models. Examples:

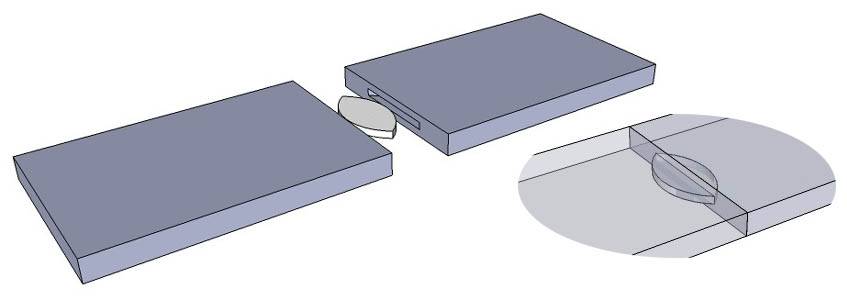

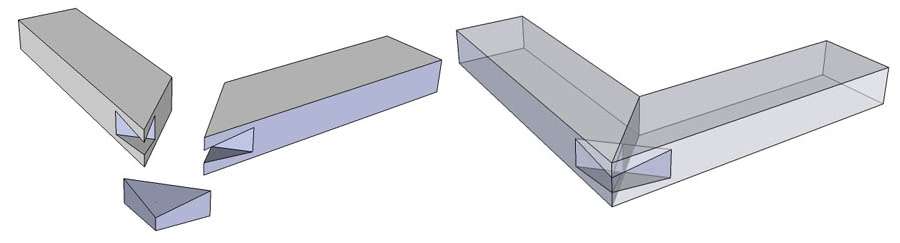

biscuit joint --- Also called a "plate joint", this is a joint made with biscuits inserted into slots cut out by a biscuit joiner. Such joints have less strength than spline joints but are easier to make. Biscuit joints have the advantage of always being blind joints. Here is a wire-frame drawing of a simulated picture frame type of construction with a single biscuit (yeah, I know, it looks a bit like two biscuits, one on top of the other but that's just an effect of Google Sketchup) inside a 45 degree mitered corner. This biscuit provides only moderate extra holding power to prevent the two sides from pulling away from each other perpendicular to the glue joint, but it provides a large amount of extra shear strength to prevent the sides from sliding past each other parallel to the glue joint.

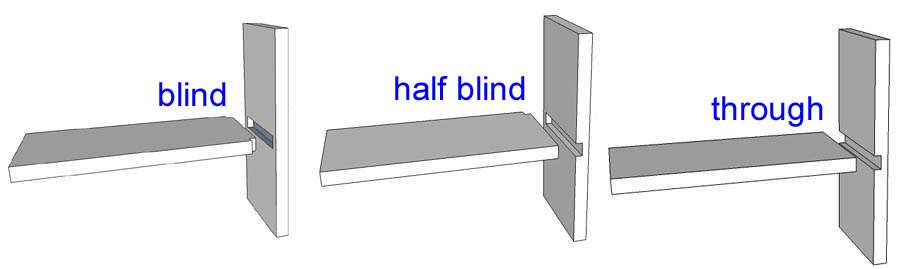

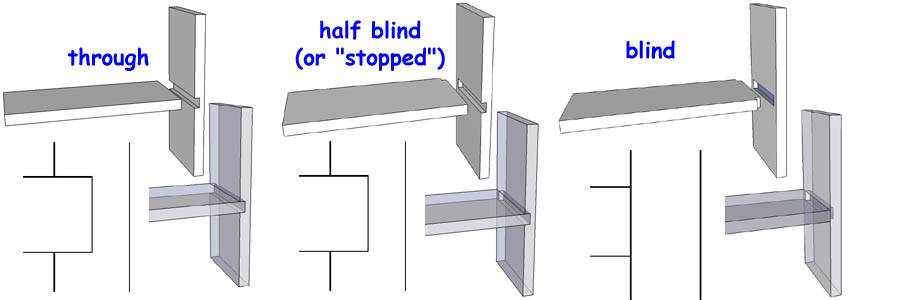

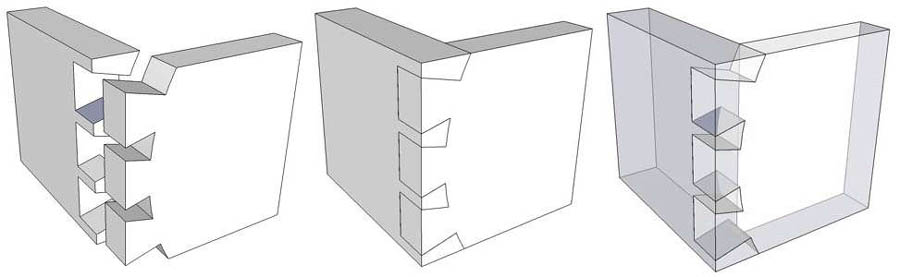

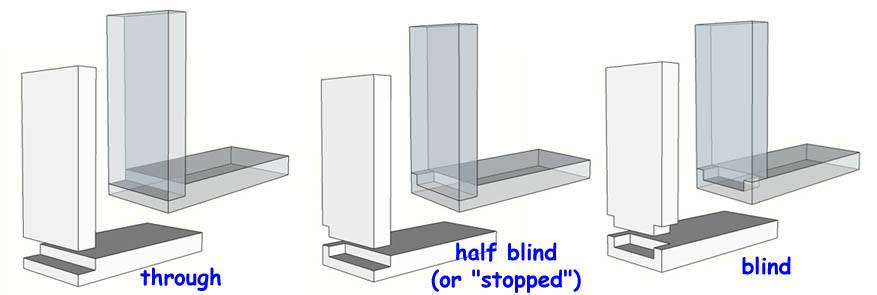

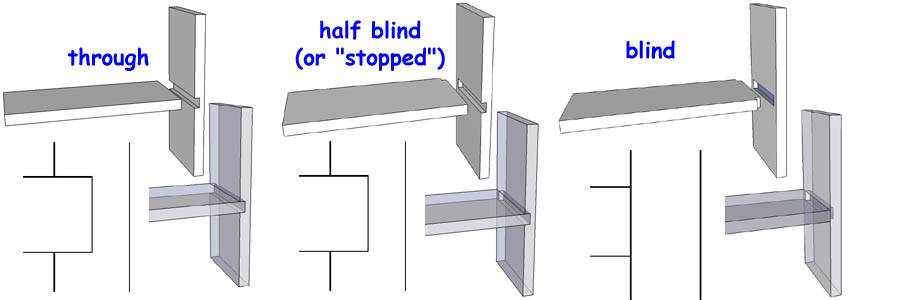

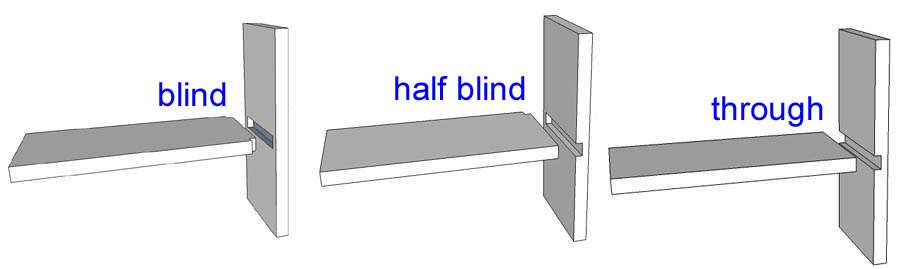

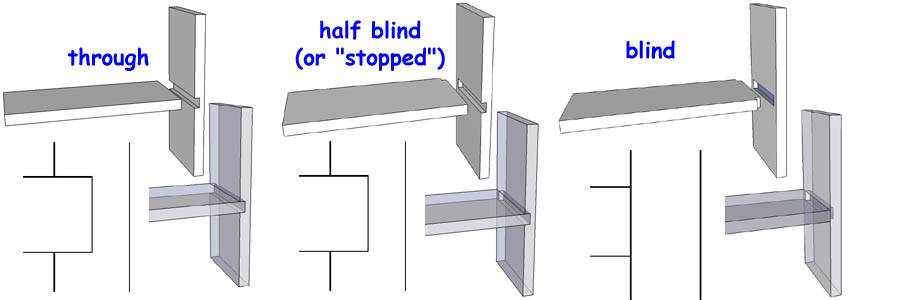

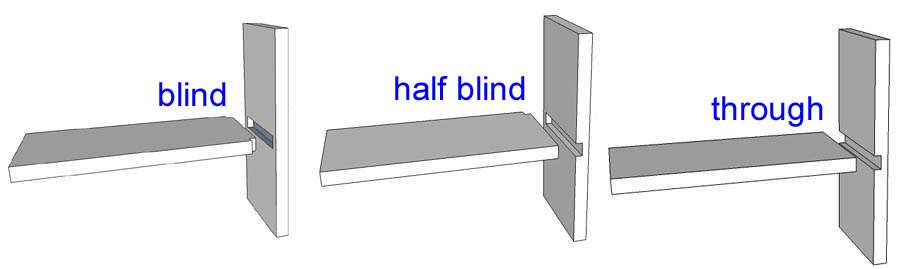

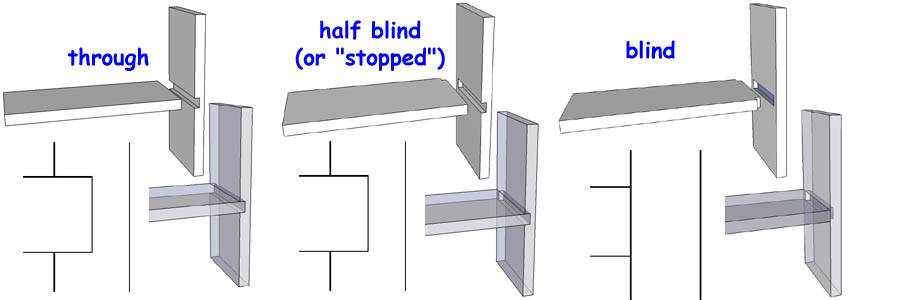

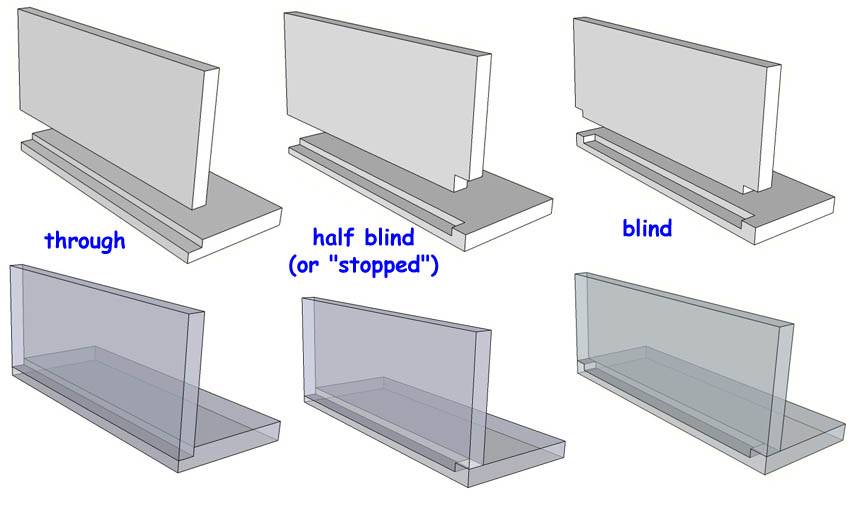

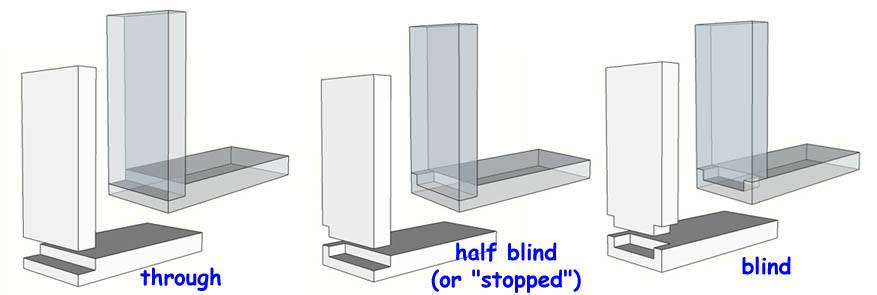

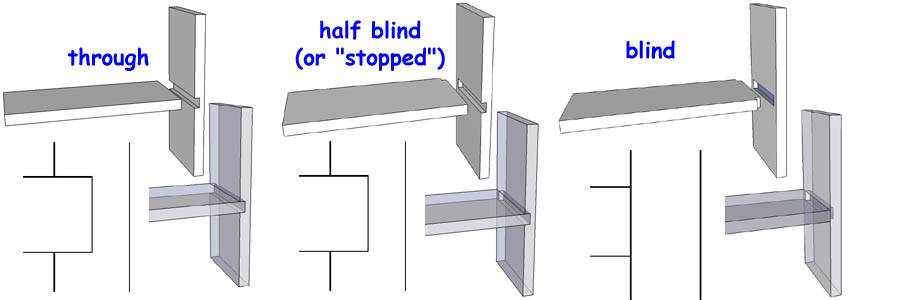

blind --- (1) As regards woodworking, this generally means "not going all the way through", so for example a finial with a mounting hole that goes half-way through the wood could be said to have a blind hole. The term "stopped" is synonymously.

blind --- (2) see blind joint

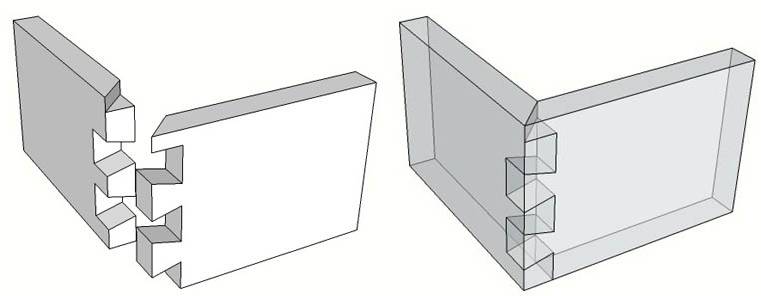

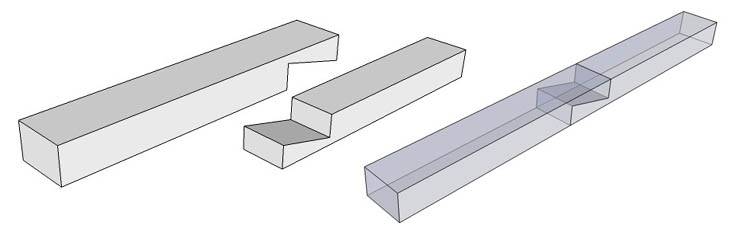

blind dado --- A dado joint (or cut) which does not go all the way from edge to edge but rather is only internal to the surface of the piece so that the edges are unbroken. If the dado cut does go through one edge but not the other, that's called a half blind dado or a stopped dado. If it goes all the way to both edges, it is a through dado. There is some confusion in nomenclature around the term blind dado in that some people use the term to mean what is actually the half blind dado. The true blind dado is rarely used, whereas the stopped dado is common and because the stopped ("half blind") dado is different from the through dado, it is often called the "blind dado" even though that is not technically correct. Also, The cut can go along the grain or across the grain, but if it goes along the grain, there is a more specific name, plough. Examples:

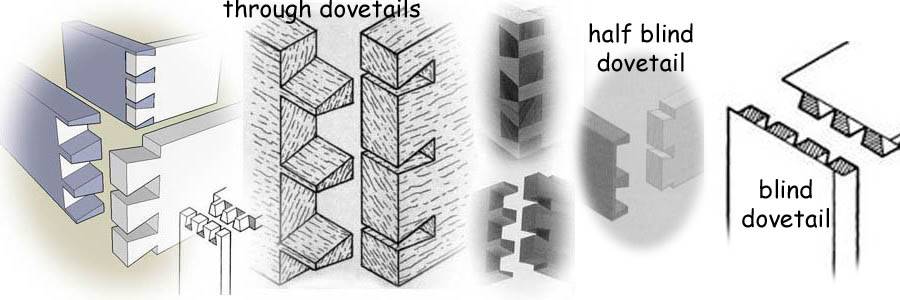

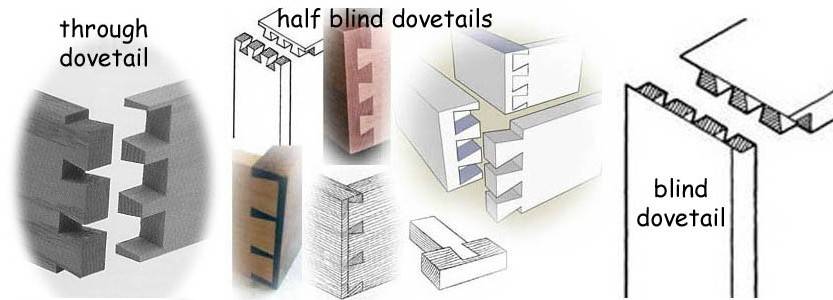

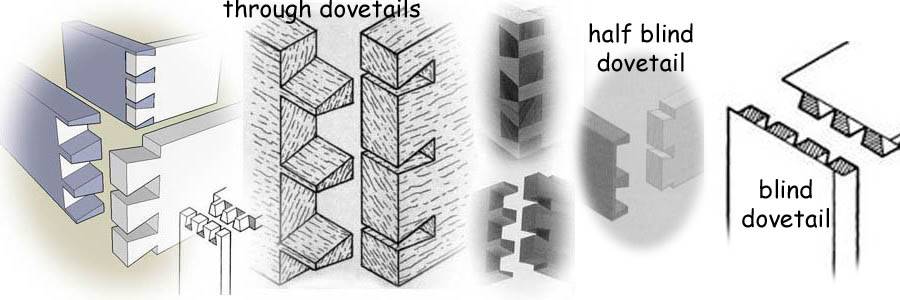

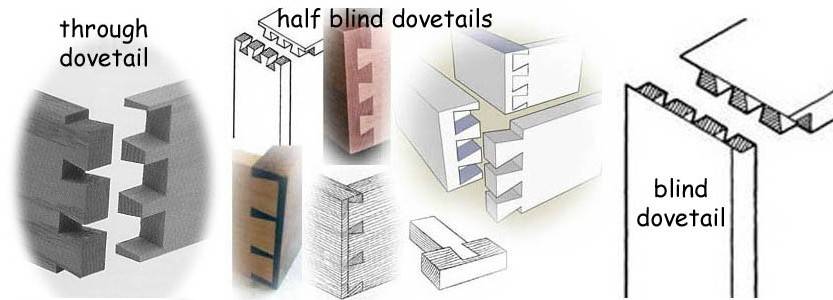

blind dovetail --- There are several ways to create a blind dovetail, including the two shown below. These are quite a chore to construct. The point is to totally hide the fact that it is a dovetail at all and just present a single clean straight joint line that makes it look like a rabbet joint but with the internal strength of a dovetail. In the examples shown, any attempt for the upper piece to pull upwards will be very strongly resisted by the dovetail. Also see mitered blind dovetail, which is even more complex. Examples.

blind edge rabbet --- see edge rabbet joint

blind end rabbet --- see end rabbet joint

blind joint --- a joint, such as a dovetail or dado, in which the intruding piece does not go all the way through the receiving piece, or in some way offsets part of the joint so that the mechanism of the joint is hidden. For example, a simple butt joint of the end of one plank across the grain at the middle of another plank could be joined with a dowel joint, a biscuit joint, or a blind dado, and you would not be able to tell the difference among them because they are all blind joints.

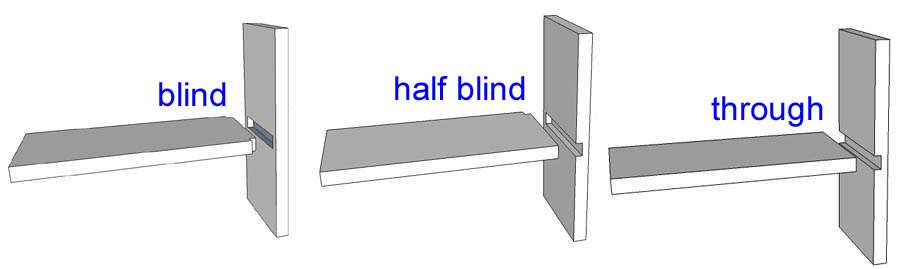

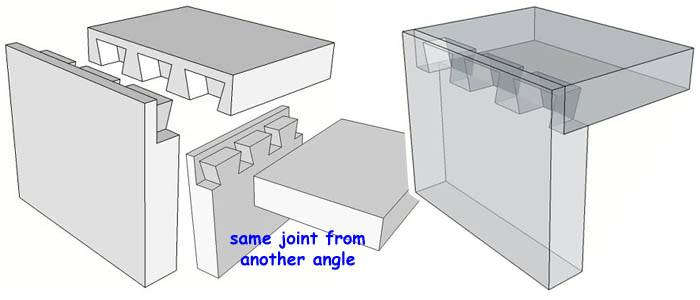

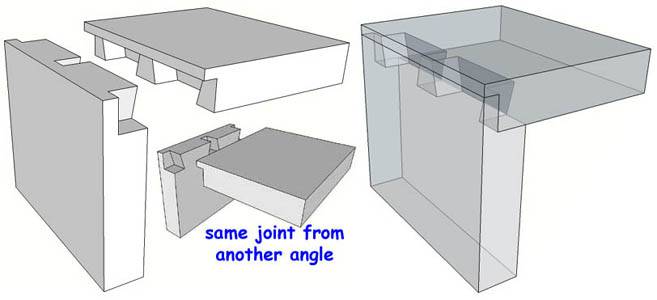

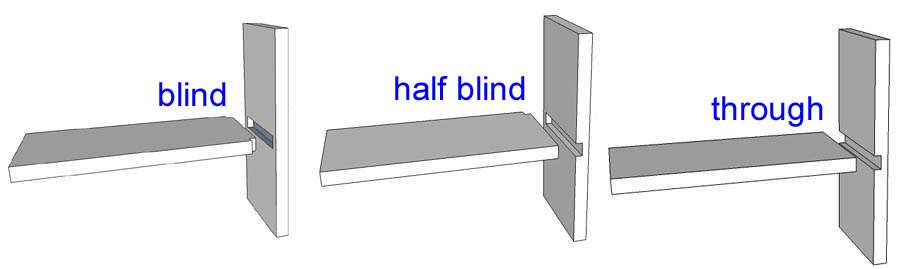

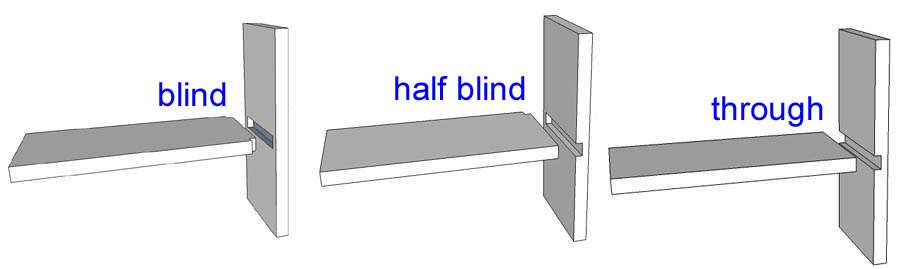

Blind joints provide the strength of a through joint, but leave unbroken edges, or an unbroken face, on the receiving piece. Blind joints are generally more difficult to produce than through joints. Compare/contrast to through joint and half blind joint. The examples below show dado joints:

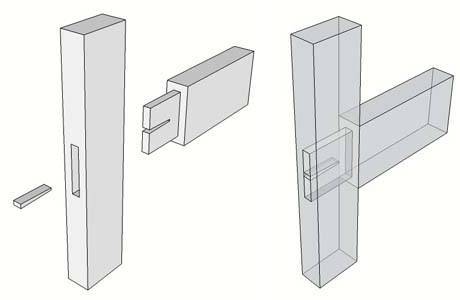

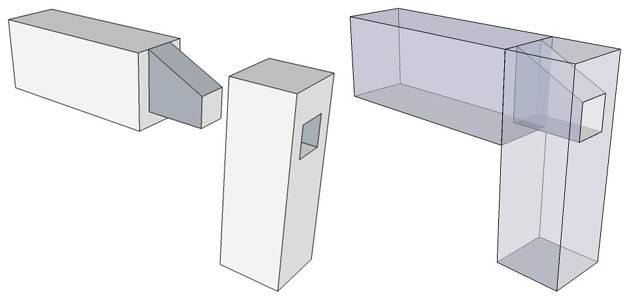

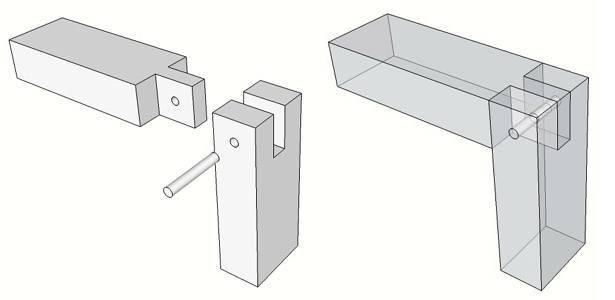

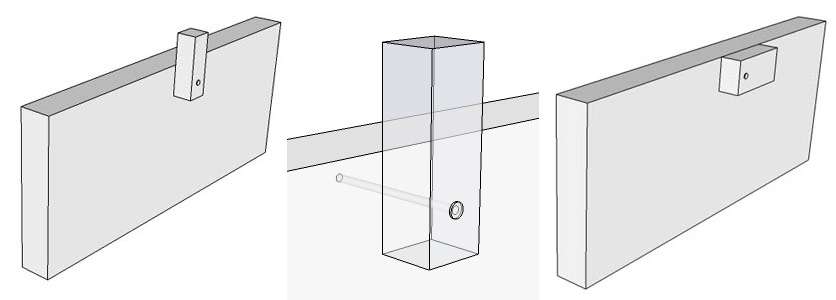

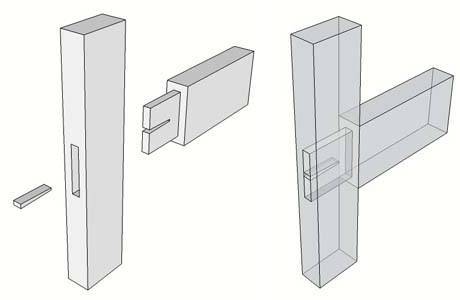

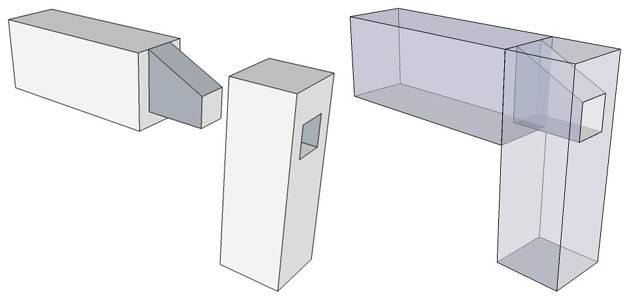

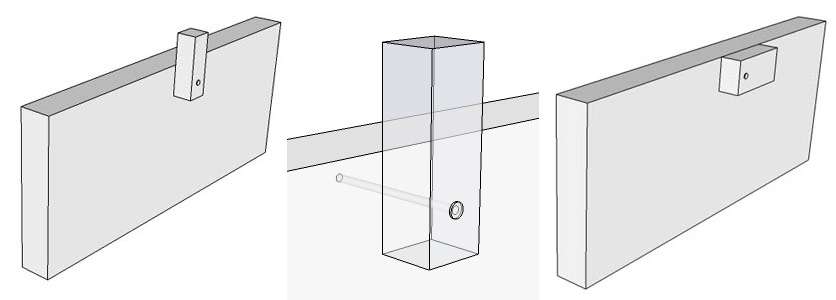

blind mortise and tenon --- A mortise and tenon joint where the mortise is not cut all the way through so that the tenon does not show on the face of the receiving piece; this is done to provide the joint strength of the mortise and tenon but to allow an unbroken surface on the receiving piece. Compare/contrast to through mortise and tenon. Some joints (e.g. dovetail and dado) have a version that is halfway between a blind joint and a through joint, and it is called a half blind joint, but the mortise and tenon does not have such a variety. The shortened tenon of a blind mortise and tenon is often called a "stub" tenon and the joint is sometimes called a stub (or stubbed or stopped) mortise and tenon. It is also called a "stopped mortise and tenon", but it is never properly called a "half blind mortise and tenon". Examples:

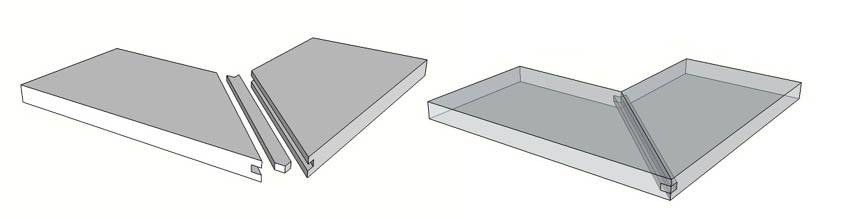

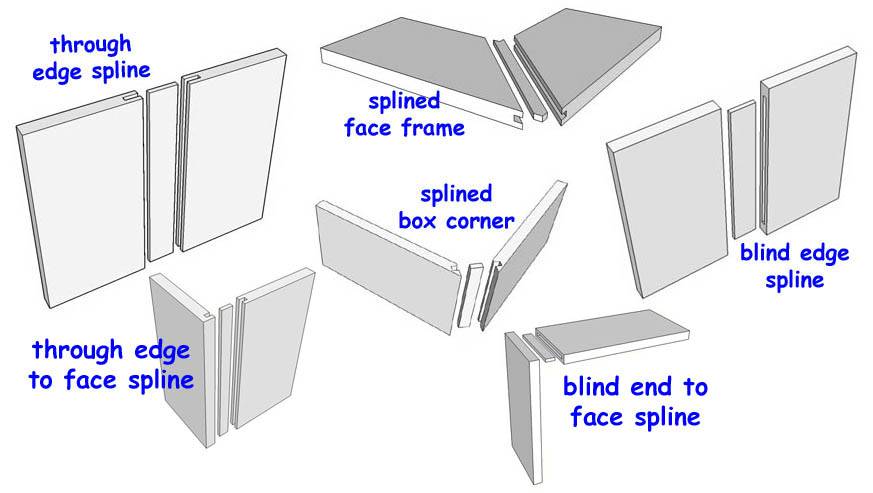

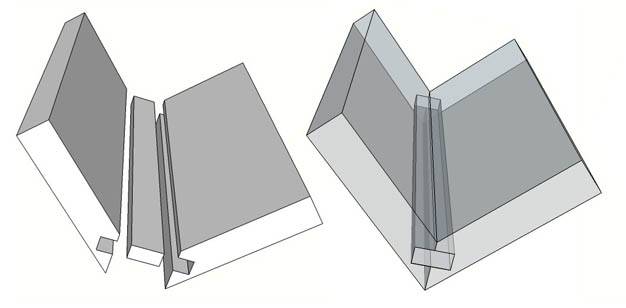

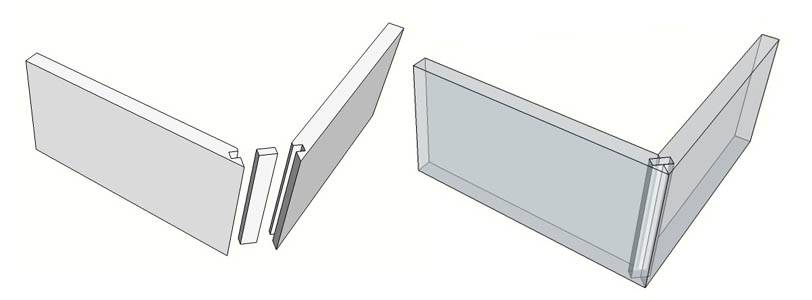

blind splined miter joint --- Any miter joint can be splined, and the spline can be done so that the joint is either blind or half blind. Here is an example of a face miter joint with a blind spline:

bowtie --- synonymous with butterfly

boxed joint --- synonymous with outlined joint and not to be confused with box joint.

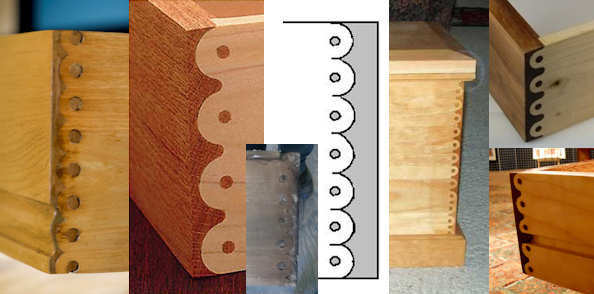

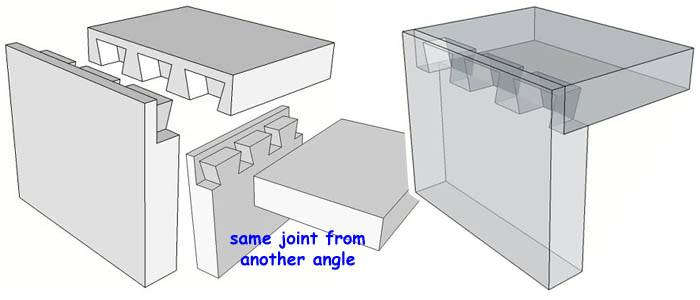

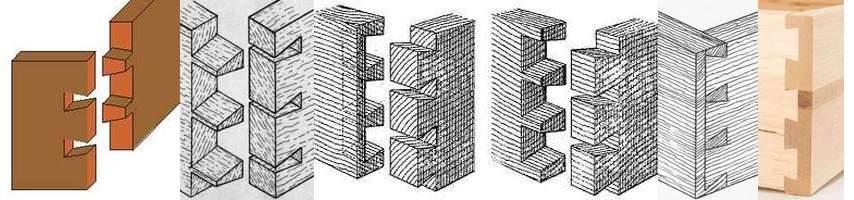

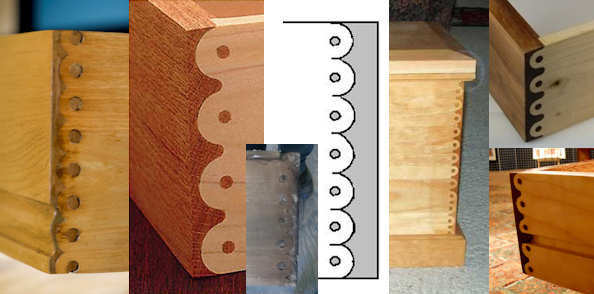

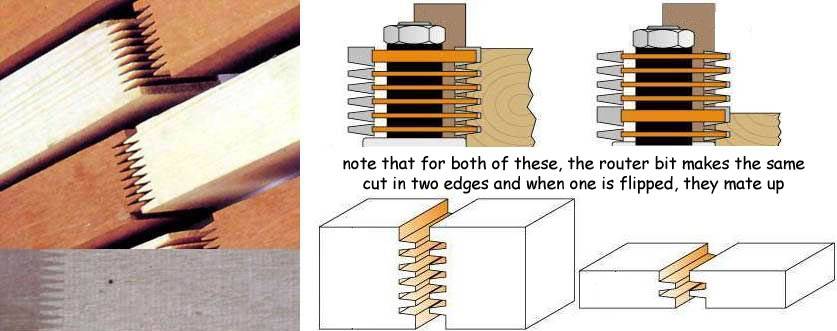

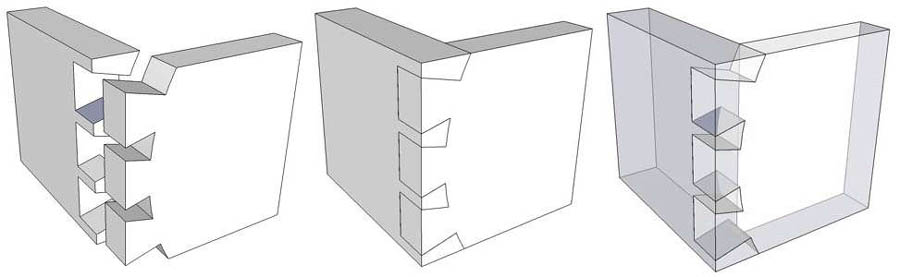

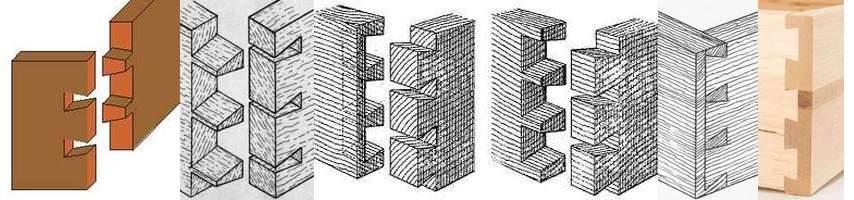

box joint --- A corner joint made up of interlocking rectangular "fingers" of wood. Has good strength due to large gluing surface area, and also has great aesthetic appeal for many people. This joint is sometimes called a "finger joint" because of the way it looks, but that term is more appropriately applied to a different joint (see fingerjoint). Examples:

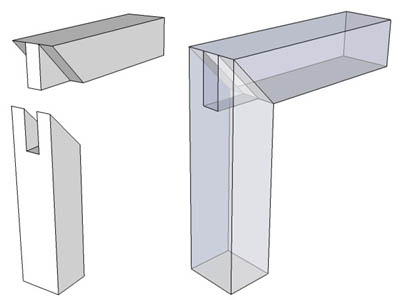

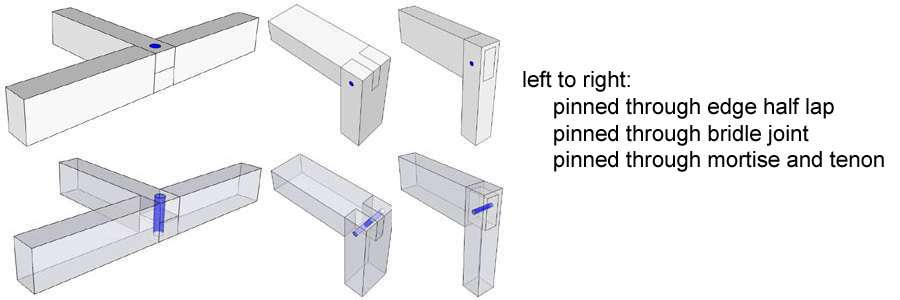

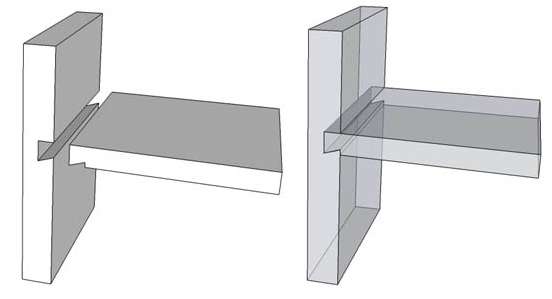

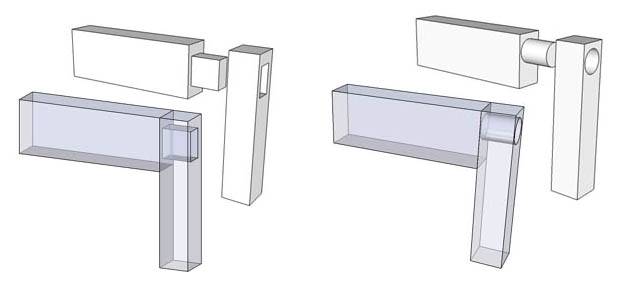

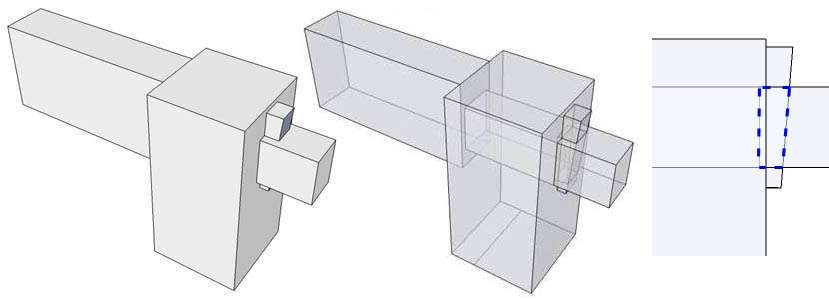

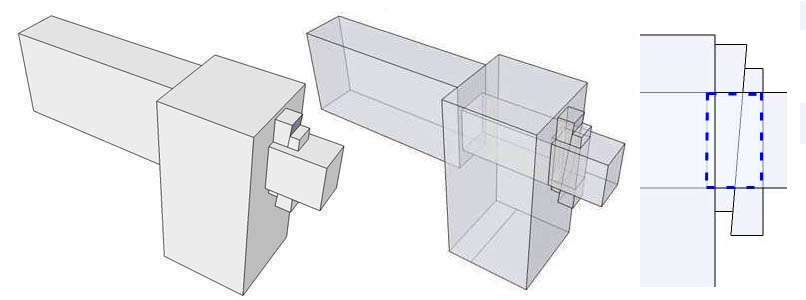

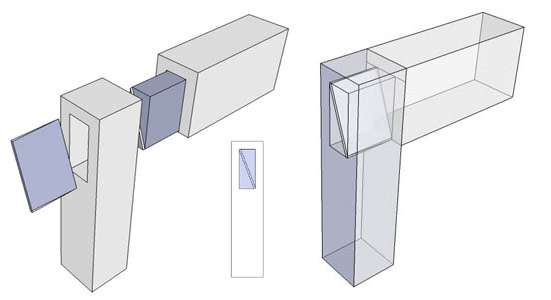

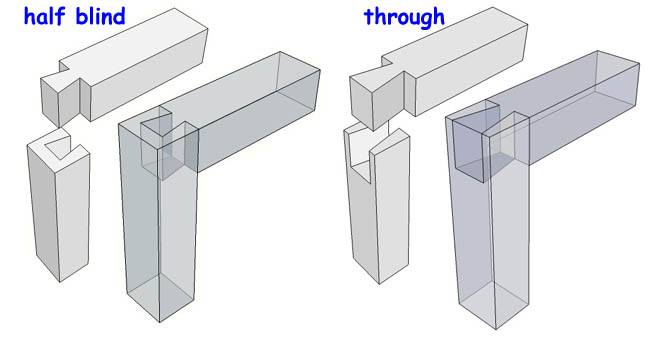

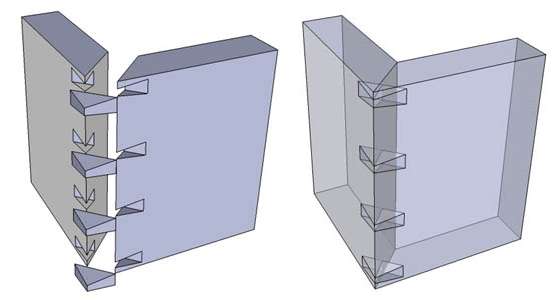

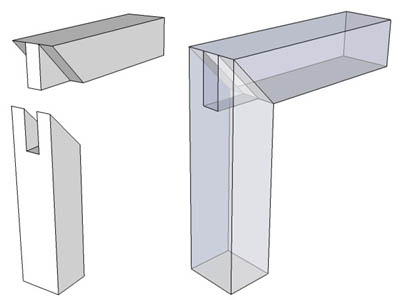

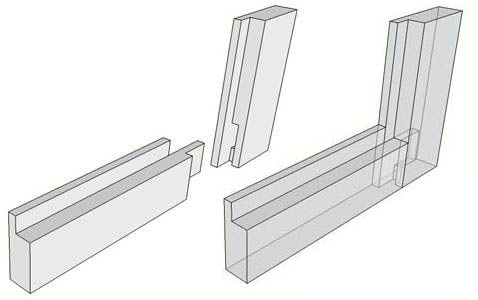

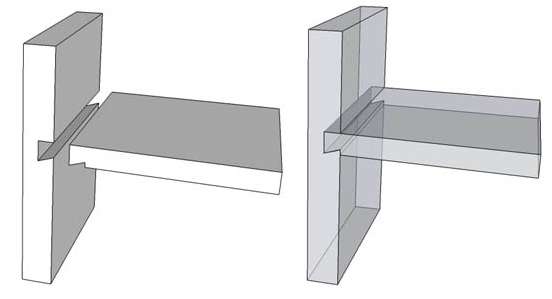

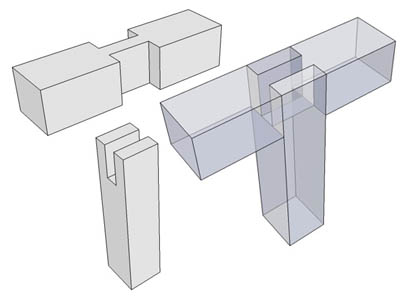

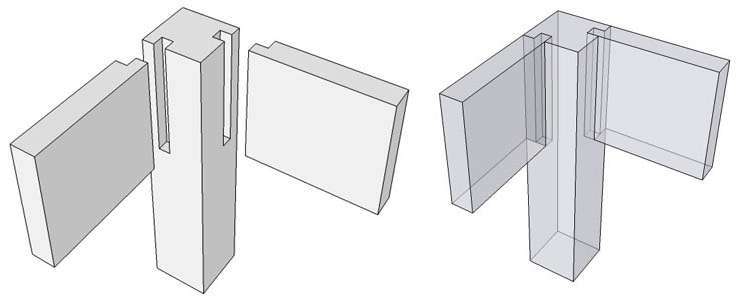

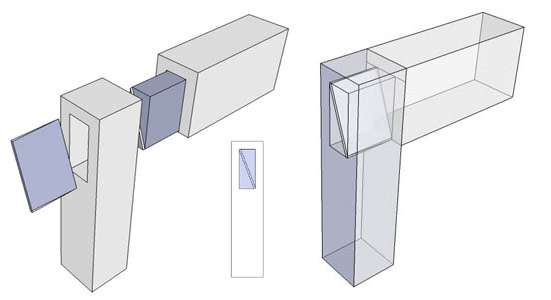

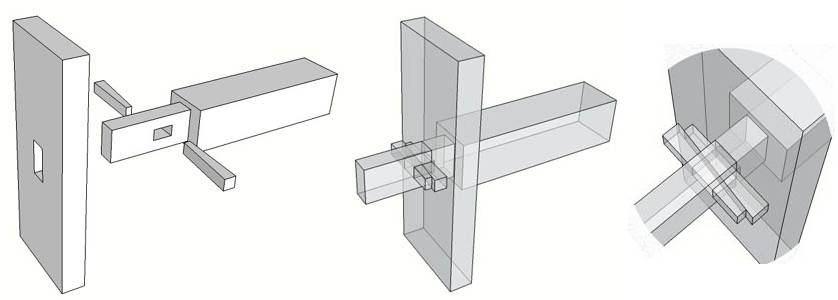

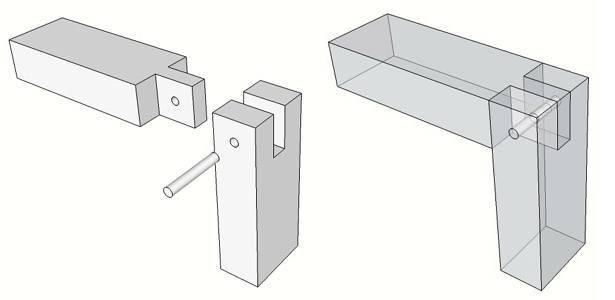

bridle joint --- A type of mortise and tenon joint in which the mortise is open at the top; that is, the mortise is slotted all the way out of the edge of the piece it's in and the top of the tenon is visible. As can be seen in the examples below, the joint can be half blind or through. A half blind bridle joint is also called a stopped bridle joint, and the joint itself is also called an "open mortise and tenon joint" and it is also sometimes called a "slip joint" because the tenon just slips into the open mortise. A pinned version can be seen at doweled through bridle joint. If the cross piece goes over the vertical bar in both directions, it's called a T bridle joint Examples:

bruzze --- This is the name of a particular type of joinery chisel that is also known as a corner chisel but that term also refers to another type of corner chisel that is illustrated with that term. The bruzze (as opposed to that other type of corner chisel) is what one normally thinks of as a joinery chisel and at the end of the normal handle and shank, it has a thick right-angle cutting end that is used to clean out corners. Examples:

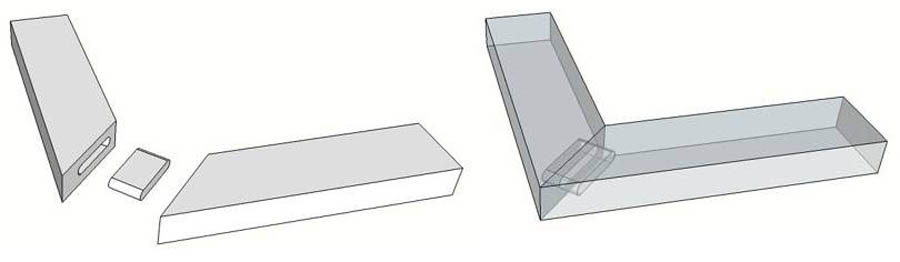

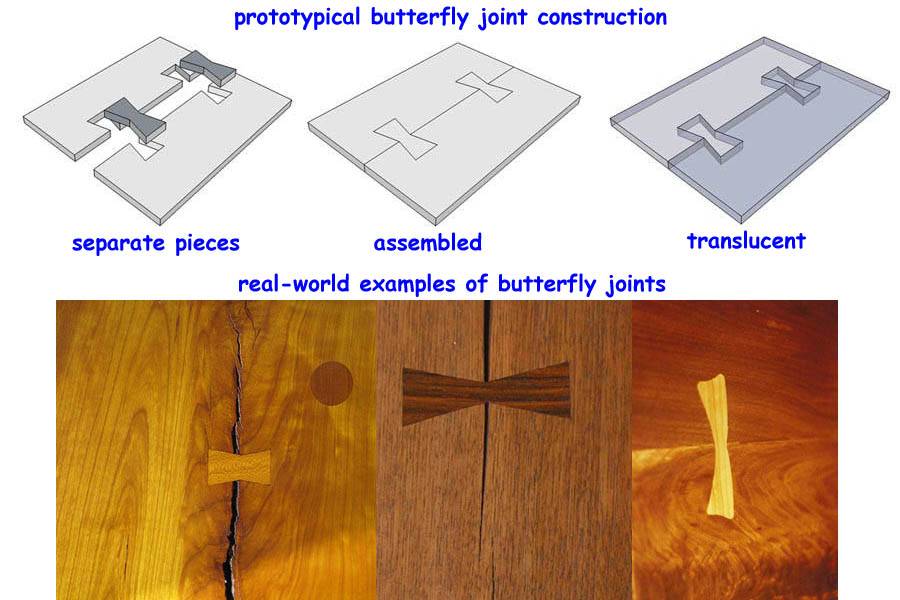

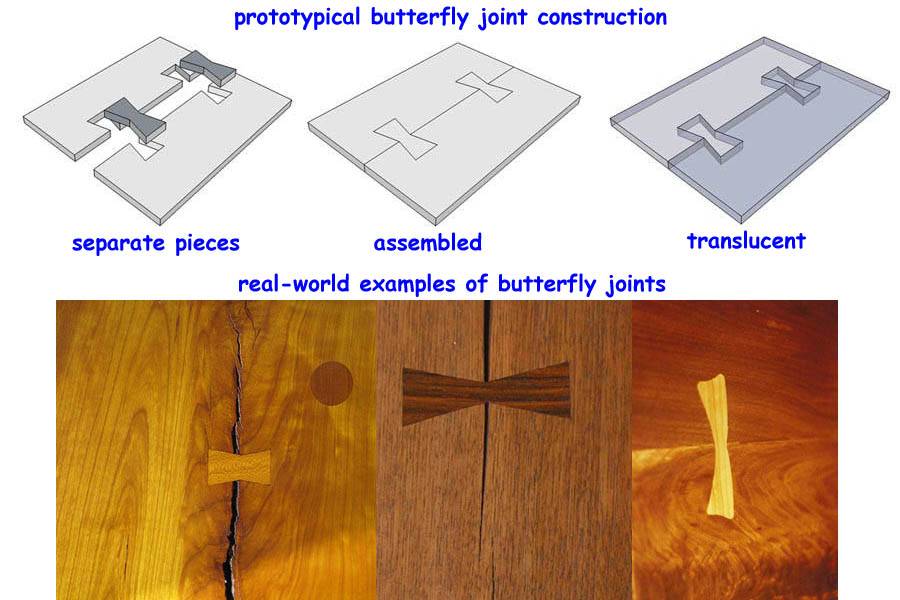

butterfly joint --- A "joint" that is most often used as an elegantly decorative way to strengthen an area that is weak or cracked, particularly when using entire planks to create a bench or a table top. It can also be used as an edge joint for undamaged planks but the highly visible nature of the joint means that aesthetics are a consideration more than would be the case with many joints. The basis of the joint is a piece of wood that is in the shape of a back-to-back pair of dovetails which together form the shape of butterfly wings, thus the name. Also called a "bowtie" because of the shape. Examples:

butterfly keyed mitered frame joint --- a face miter joint that is strengthened with a butterfly type key. Example:

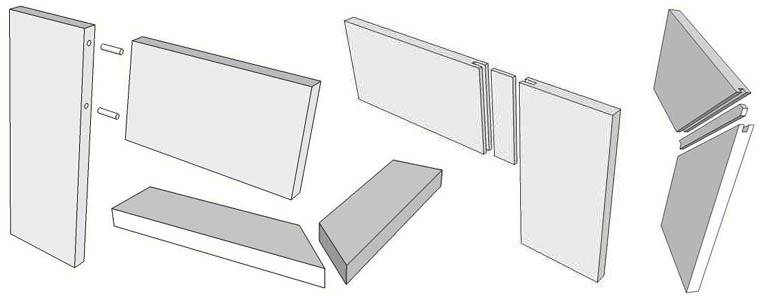

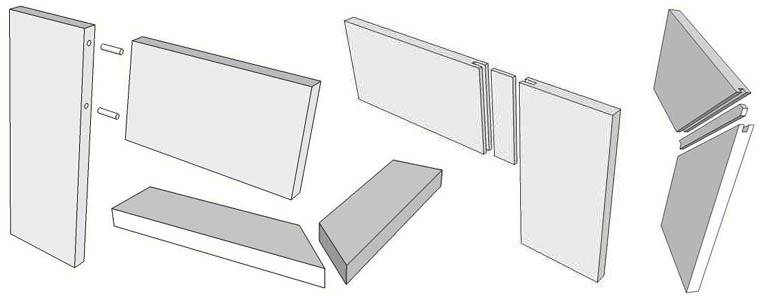

butt hinge --- The "normal" or "standard" hinge that you see most often on small eveyday objects such as cabinets, doors, jewelry boxes, etc. The butt hinge is what most readily comes to mind when most people think of hinges. See hinge parts for a discussion of the parts that make up the hinge. If the butt hinge is hefty enough to hold a house door, it will often be called a door hinge. A very long version of the butt hinge is the piano hinge. If there is a crank in one or both of the leaves it is called a cranked hinge. Butt hinges are most often mortised into both the door frame and the edge of the door, but they work fine without one or both mortises, it's just that this would leave a noticeable crack at the door edge. Examples:

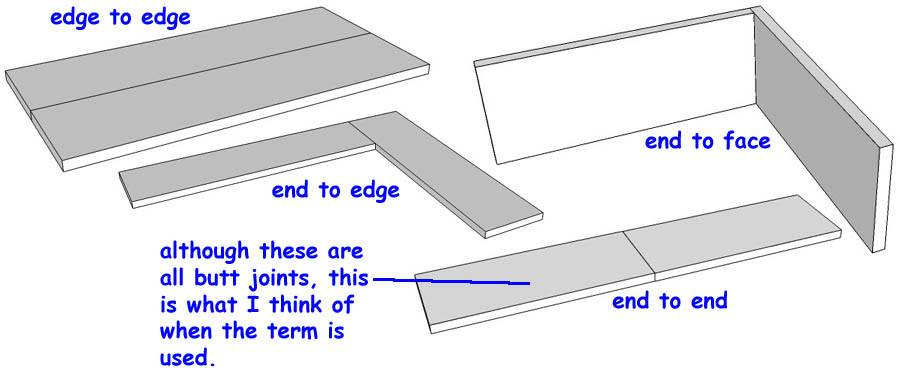

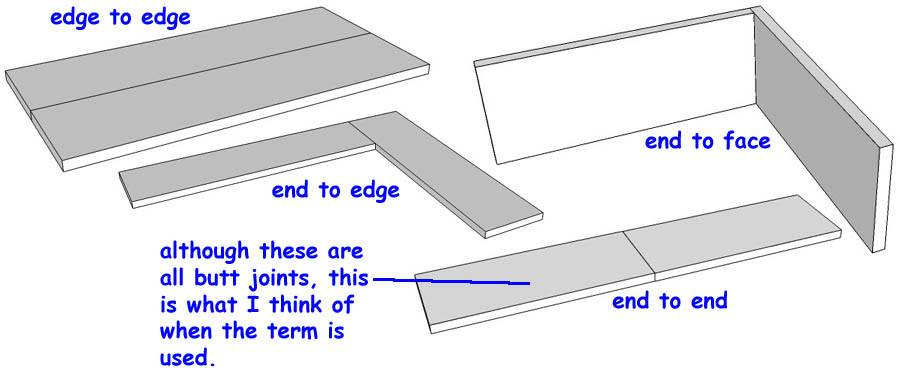

butt joint --- Most formal definitions give this as "A joint formed by abutting the squared edges of two pieces", which of course can mean any two edges, but this seems wrong to me, since the "butt" of a plank is the END, not the edge and in common usage, "butt joint" far more often agrees with my own sense that it means butting the ENDS of two planks. The phrase "to butt up against" is even more vague and can even encompass face to face "butting", so I consider this to be a vague term. Examples:

cabinet maker --- A skilled craftsman who specializes in making fine furniture including, but not limited to, cabinets. See also cabinetry. Compare/contrast to carpenter.

cabinetry --- The craft of making furniture (especially furniture of high quality including, but not limited to, cabinets) utilizing various woodworking skills including joinery. See also cabinet maker.

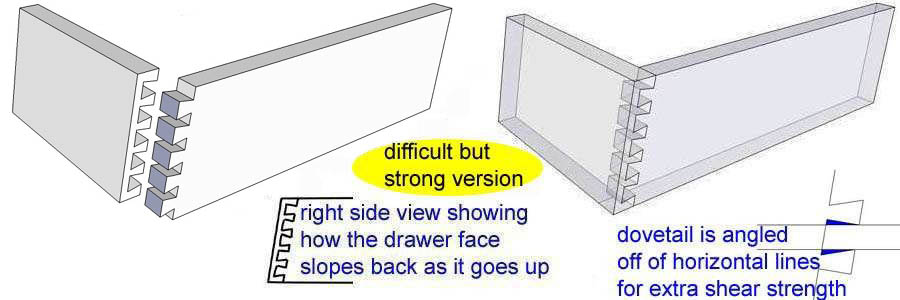

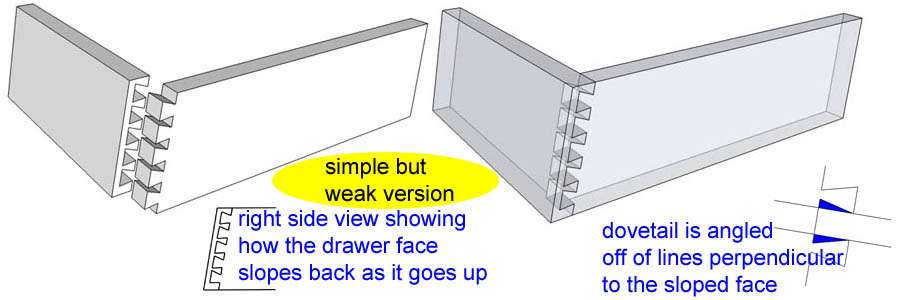

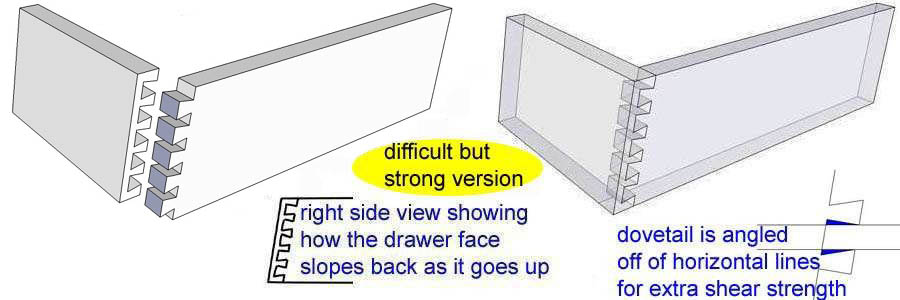

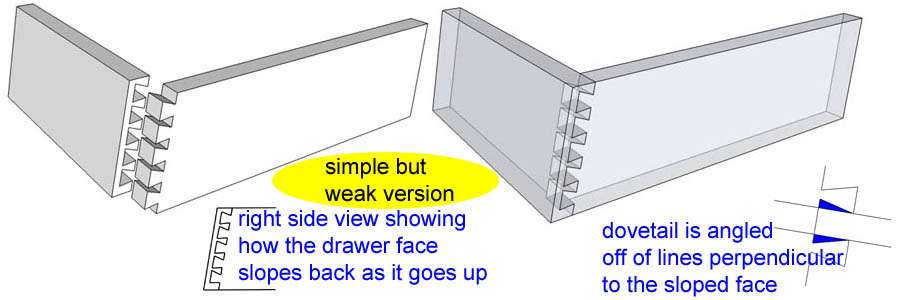

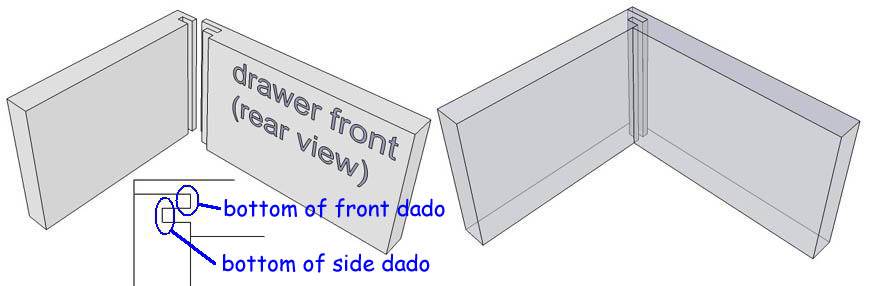

canted half blind dovetail --- When a drawer front is tilted (canted) backwards a little, as is the case in (for example) dressers that are wider at the bottom than at the top, some care needs to be taken in doing dovetails at the corners of the drawers, if dovetails are the joint of choice for the particular application. The problem is that if you make the dovetails based on the slanted edge of the drawer side, they will be easy to make with a standard jig, but they will be mechanically weaker than if you tilt them over a little. The reason for this is that in the "easy but weak" version the grain runs close, or even exactly, parallel to the lower surface of where the tail and pin meet, which means that the joinery adds no strength at that point, and the upper part of the tail/pin area presents an easy shear. Thus, the side could pull out, leaving behind the sheared off upper portion of each tail, with the lower portions of each tail having simply slid out. In the "difficult but strong" version, the upper portion of each tail could still shear off but it's not as likely because the lower portion exerts pressure that keeps the side from pulling out even if the glue fails, plus of course the lower area has joinery strength in addition to the glue. Examples:

captive piece --- When two pieces of wood are joined with a screw, the screw goes through one piece, which is called the "captive piece" and into the other, which is called the "anchor piece".

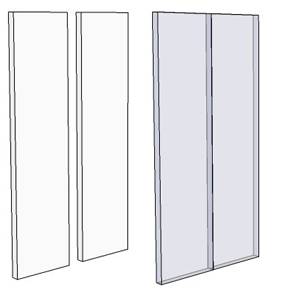

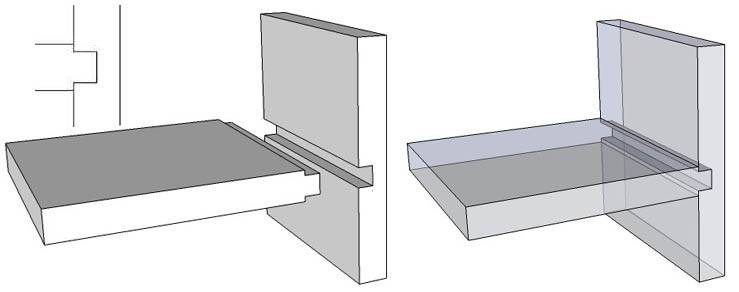

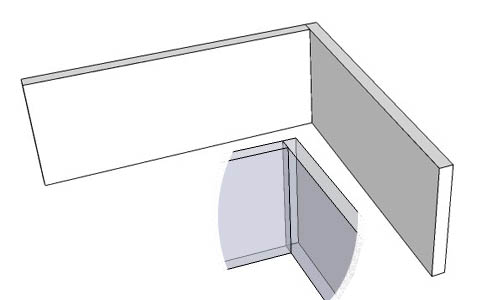

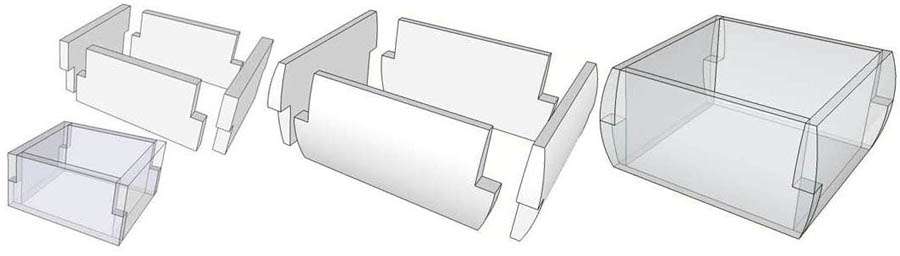

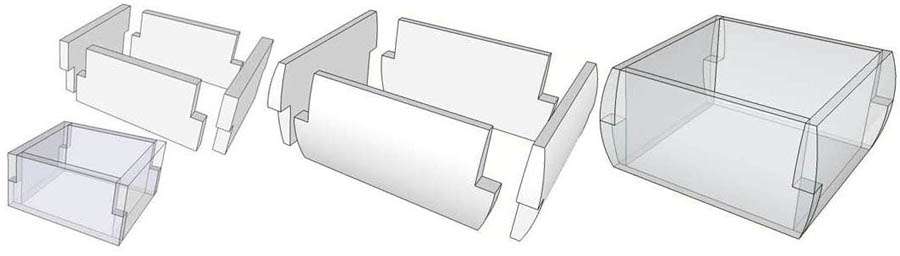

carcass --- The case or box of a piece of furniture. It is the rough framework and structure of the item into and onto which the cabinetmaker will eventually put a a top, drawers, edging and so forth. Often the front of a carcass will be covered by a face frame to hide raw plywood edges and to give extra support to doors. Carcasses include drawers, cabinets, bookcases, and so forth. The art of constructing joints for carcassses is called carcass joinery, and this is one of the two main categories of joinery, the other being frame joinery. Examples:

carcass joinery --- There are two fundamental types of joinery, carcass joinery and frame joinery. Carcass joinery is the art/science of attaching planes (of either solid wood or plywood) to form boxes. This is used for such diverse items as drawers, cabinets, bookcases, etc. Most joint types can be used for both frames and cases, but the types that are associated mostly with cases include dovetail joints, dado joints, rabbet joints, and box joints. Also called "case" joinery.

carcass joint --- A carcass joint is any joint used in the construction of a carcass (as opposed to a frame). See carcass joinery.

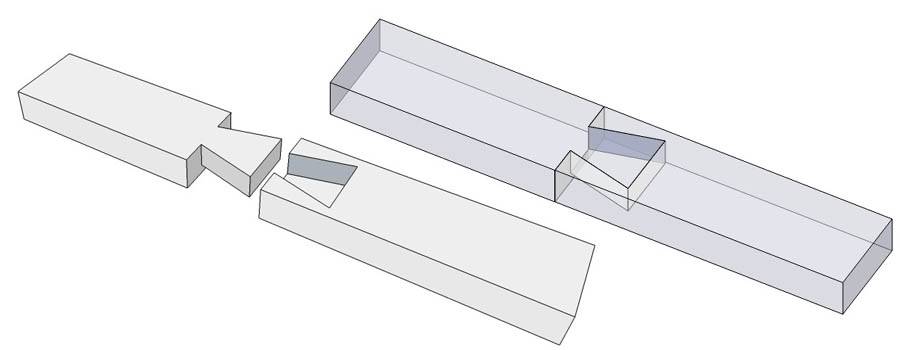

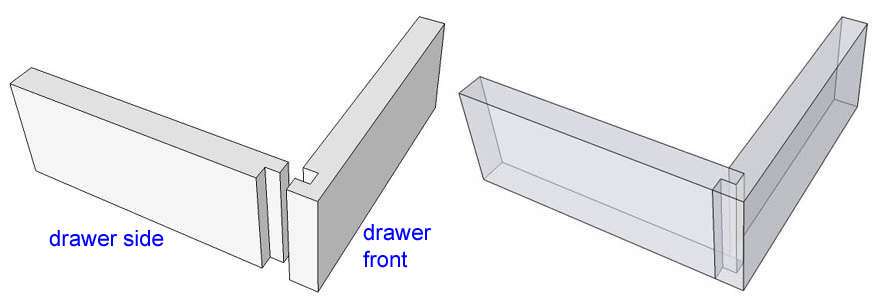

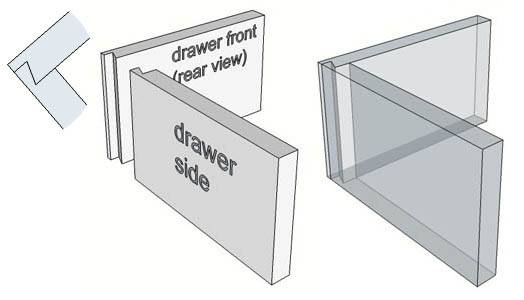

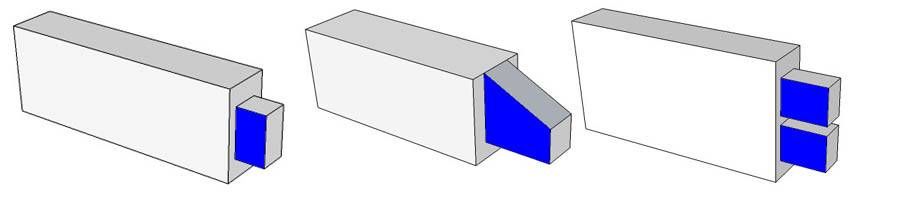

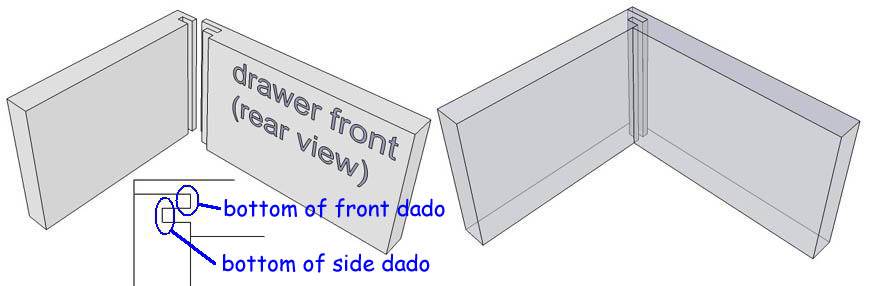

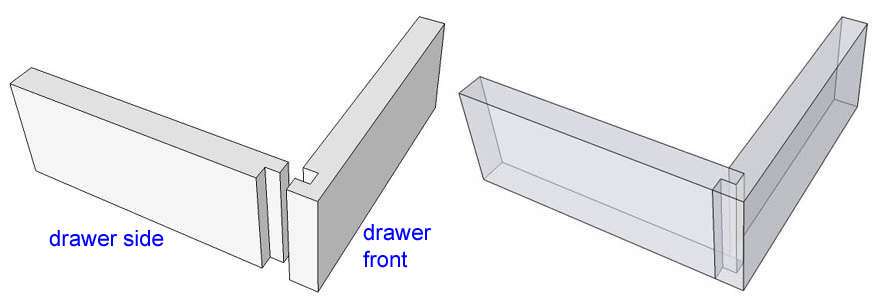

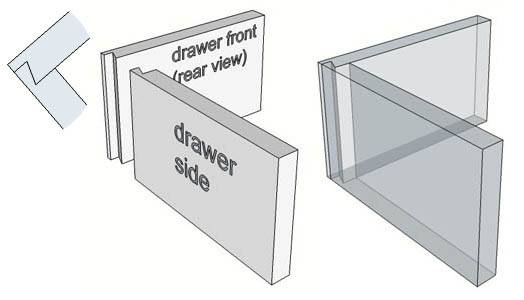

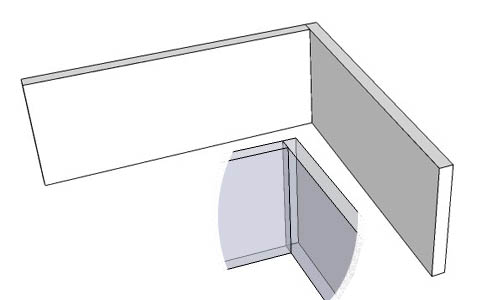

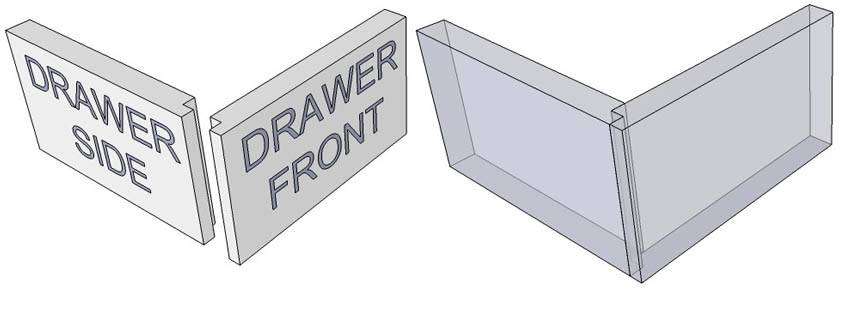

case joint --- In general, "case joint" is synonymous with carcass joint but there is one carcass joint that is sometimes specifically called the case joint and that is the simplest type of joint for a drawer front/side; the joint just butts the end of one plank (the drawer side) up against the face of the mating plank (the drawer front). The joint can be just glued, or it could be reinforced with biscuits or dowels. With no reinforcement it is a very weak joint. Compare/contrast to drawer locking joint and end miter joint. The case joint is also called an "end to face butt joint". Examples:

cheek --- The vertical side of a tenon. (see also vise cheeks) Example:

cogged --- There is a particular kind of scarf joint that is sometimes called a cogged scarf joint and I list it as such in this glossary, but I am not confident in the term. In researching "cogged", I found vague definitions, some of them contradictory, and no illustrations, and I am not confident that I know what it really means. Here are some of the entries I found, to at least give you a flavor of the term:

- cog --- the tongue in one timber, fitting into a corresponding slot in another.

- cogging --- A carpentry joint formed by two crossed structural timbers, each of which is notched at the place where they cross.

- joists and binders are connected by cogged joints

- mortise and tenon is a type of cogged joint

- The joint between rafter and chord is realized by a cogged joint

- " ... cogged joints, hereinafter generally referred to as notching ... "

- cog --- A tenon projecting from a wooden beam designed to fit into an opening in another beam to form a joint.

- cogging --- To join with tenons

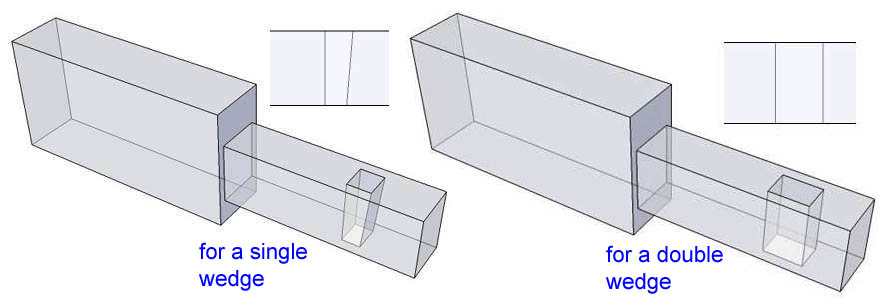

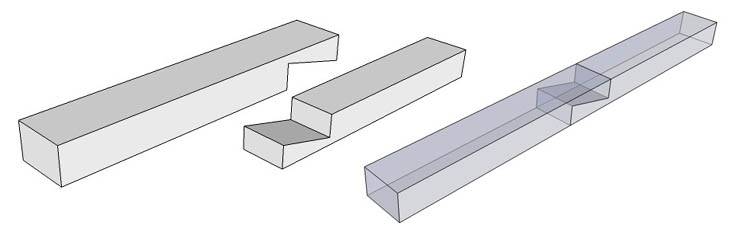

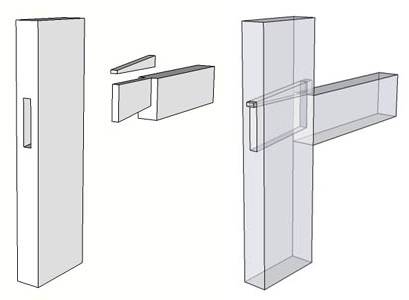

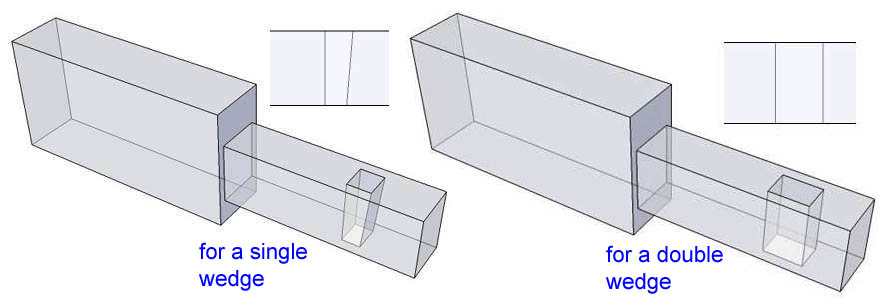

cogged scarf joint --- The term cogged is one that I have been unsuccessful in pinning down exactly, and the joint that I show here is one that I am not sure the term really applies to, but it's the term used with the joint where I found it, so I present it here. It is, at least in the example I found (and illustrated below) a double wedge (the term folding wedges is also used) put in the middle of a joint that is a slightly complex tabled scarf joint. For a knockdown joint the wedges can be left protruding slightly so that they can easily be tapped to remove them and disassemble the joint (which of course would not be glued). For a permanent joint, glue the wedges before tapping them into place, along with gluing the rest of the joint. This looks to me to be a very strong joint, but overly complex for most uses. Example:

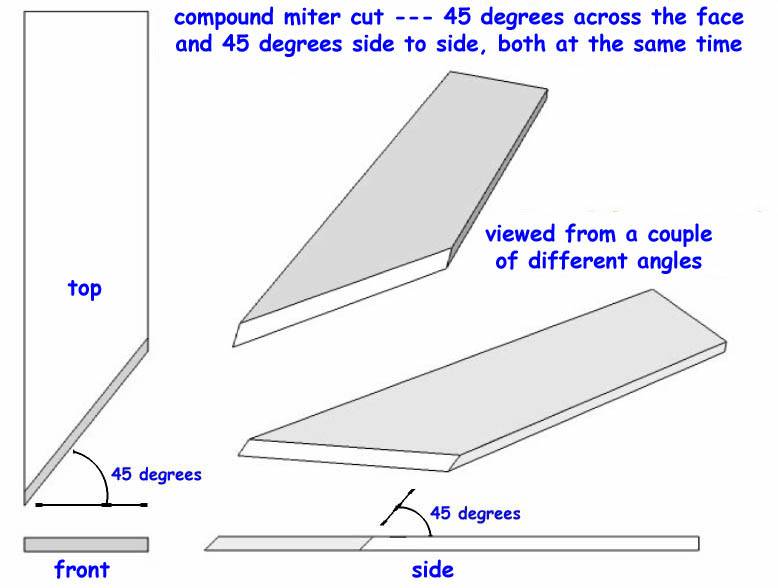

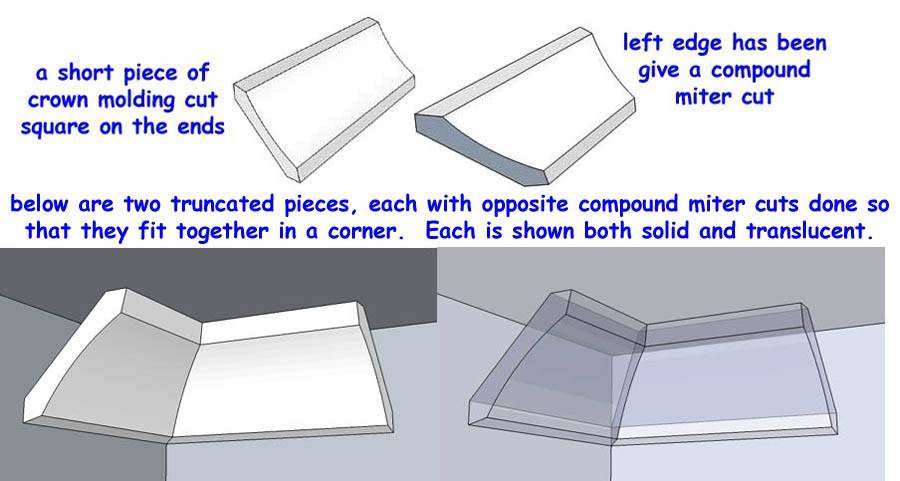

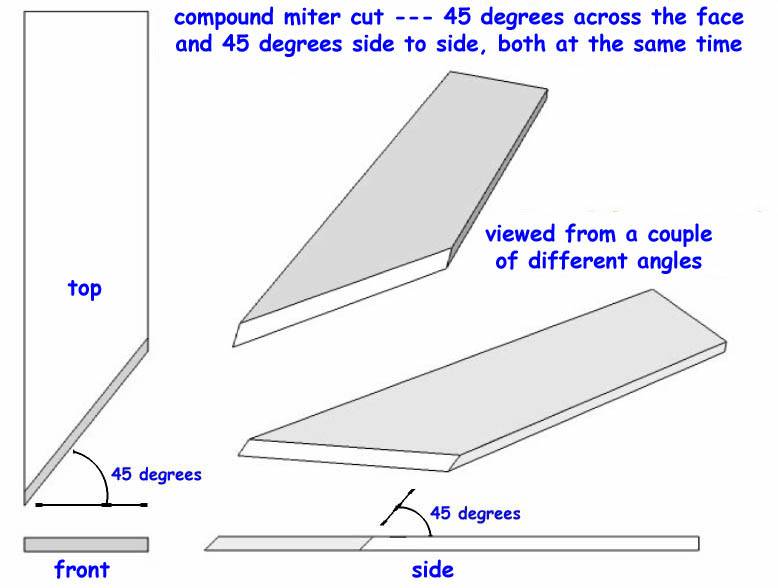

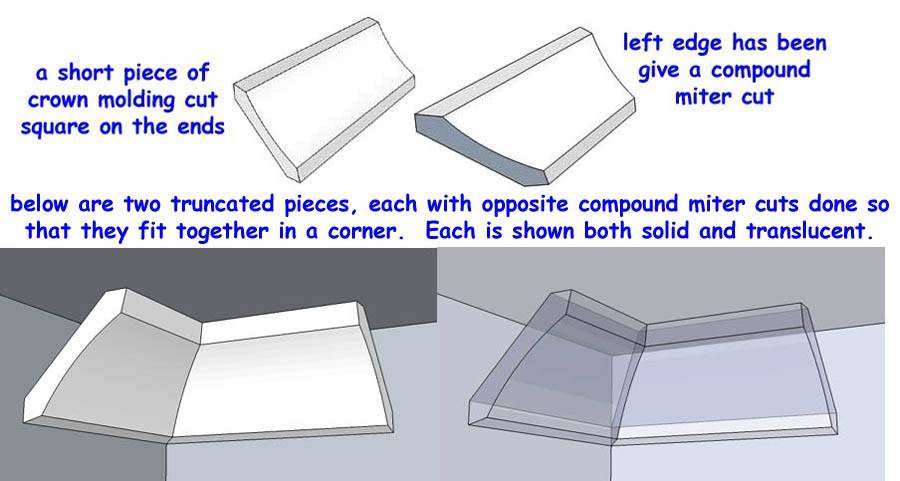

compound miter cut --- A miter cut which is at an angle to both the edge and face of a board at the same time. The most common use of compound miters is with crown molding, but there are many other uses as well. Here is an example of a compound miter. In this particular example, the board has been crosscut at 45 degrees to the length and also cut at 45 degrees to the face:

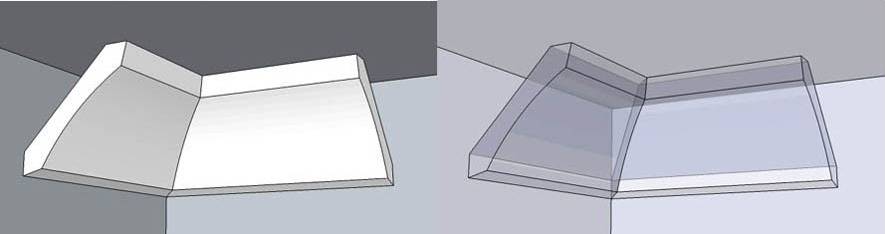

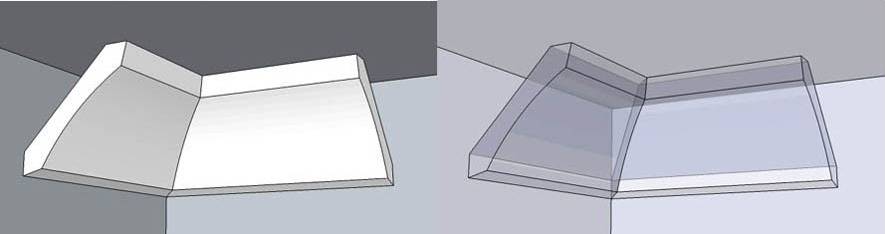

compound miter joint --- Any joint that makes use of a compound miter cut. The most common uses of this cut are in crown molding and in the construction of "boxes" that have more than 4 sides and are tapered (very common in planters, for example). Here's an example of a compound miter joint shown in two truncated pieces of crown molding that joint at the corner of a room:

compound miter saw --- One of the two major innovations in large woodworking tools in the last 20 years (the other being the biscuit joiner), this variation on the older cut-off saw is a highly versatile and very accurate tool for making angled crosscuts in wood up to a modest sized width, and there is a variation called the sliding compound miter saw that will go to wider lengths. This is a circular saw with the blade in a swivel mounting that is brought down onto the wood and the swivel can be angled in two planes; think of putting your hand out in front of you with the palm vertical and the fingers pointing away from you. You can move your fingertips right and left with the palm still vertical and/or you can angle your palm to the vertical. That's what the compound miter saw can do. It is available in both AC powered and battery powered versions. Examples:

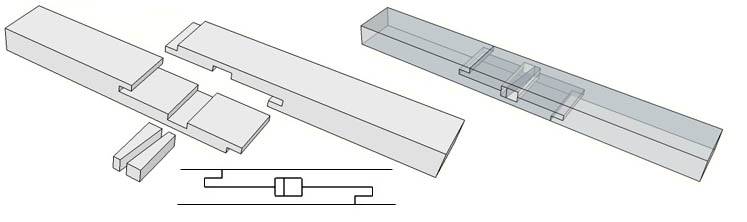

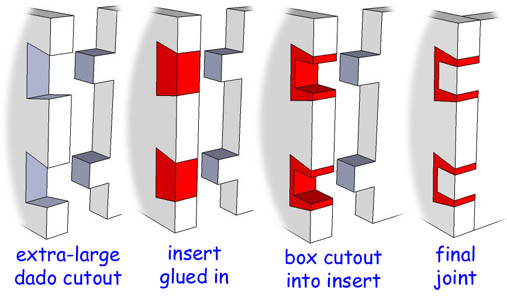

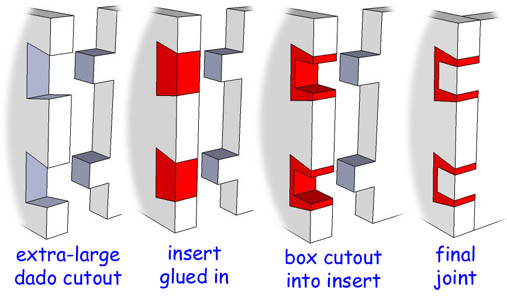

conversion joint --- An outlined joint that converts a dado joint to/from a boxed joint. This is never done for structural reasons, only for decoration. It is done by putting an extra wide and extra deep box or dado joint at the end of a plank, then glueing into that a contrasting wood pin that does NOT yet attach to anything else, then cutting into the insert the other kind of joint into which a pin from the other plank that forms the joint fits. Example (dado to box):

coopered edge joint --- An edge miter joint that is made with a compound miter cut. Such joints are used to make barrels (thus the reference to cooperage in the name) but are also used to make planters or any other box-like construction that requires a changing width over the length.

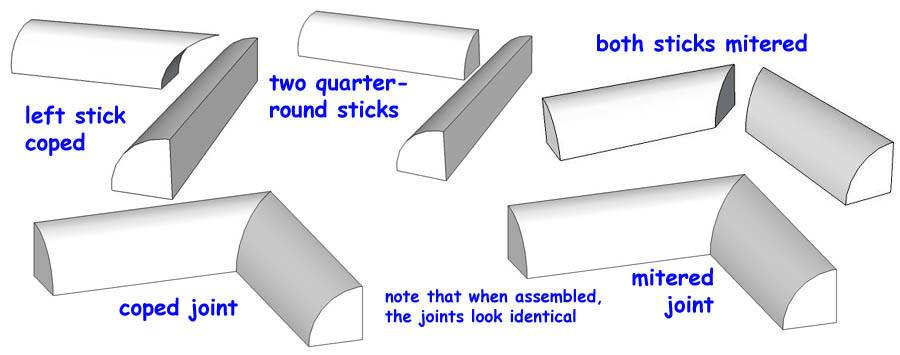

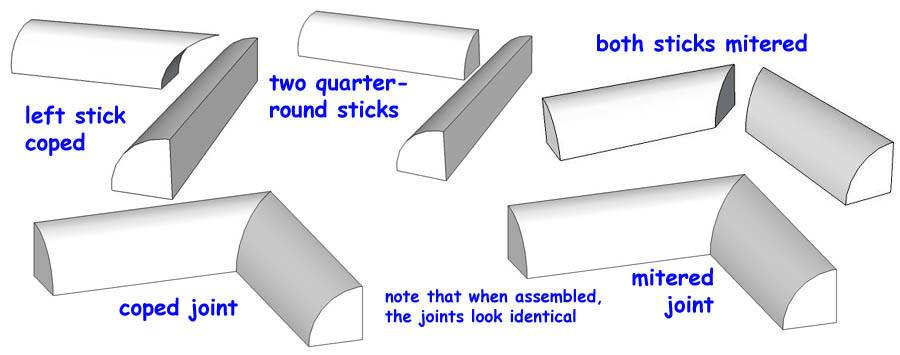

coped --- Cut with a coping saw. This normally implies a curved cut. See also coped joint

coped joint --- Molding pieces that need to meet in a corner are normally cut with a miter cut (or a compound mitercut if needed), but there is an alternate method called the coped joint. In this technique, one of the pieces to be jointed is just cut at 90 degrees and the other is cut with a coping saw in a curve that matches the outline of the other piece and then the coped piece is just butted up against the other. One advantage of the coped joint over a mitered joint is that when movement in service causes contraction in the molding wood, a mitered joint makes the separation obvious but the overlapping edges of a coped joint do a much better job of hiding the separation. The illustration below shows both a coped joint and a mitered joint for quarter-round molding. Note that once assembled, the joints are indistinguishable.

coping saw --- A hand saw used to cut intricate curves and cutouts. It has a very thin blade, usually about a foot long, and usually about a 6 inch throat. It is widely used to cut dovetails and it is also used to make what are called (no surprise here) "coping"

cuts in molding to create coped joints as opposed to miter joints. In a coping cut, the end of one piece of molding is cut to fit the shape of the surface of another piece of molding so that they go together differently than with a miter joint, in which the ends of both pieces of molding would be given a miter cut. There is another, very similar, saw that is designed for even more intricate work than the coping saw and that is the fret saw. Examples:

corner chisel --- A heavy joinery chisel that has a right-angle end and is used for cleaning out corner areas. There are really two forms of this. One (the one illustrated here) is a small chisel end embedded in a metal block and it is struck with a hammer or mallet. The chisel part is captive but moveable and usually has a spring that keeps it in place except while it is struck with the mallet. The other is a more normal joinery chisel with a long shank and a wooden handle; it is also struck with a mallet. The "normal chisel" type is called a bruzze and is illustrated with that term. Examples:

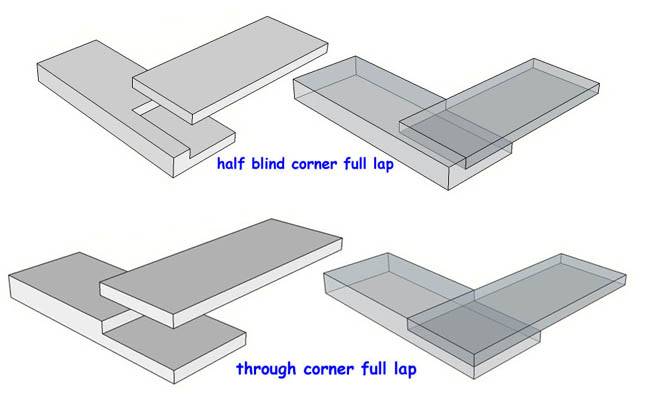

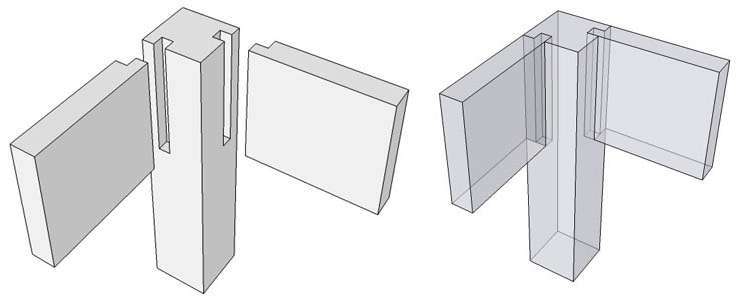

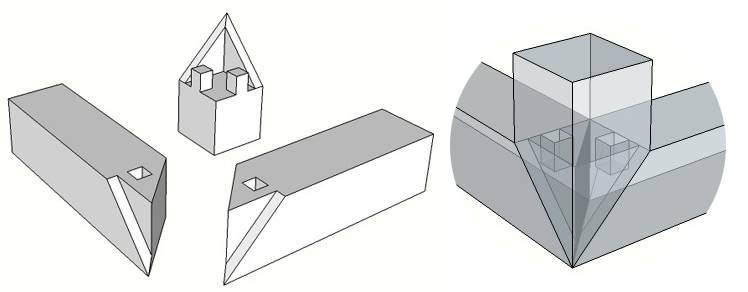

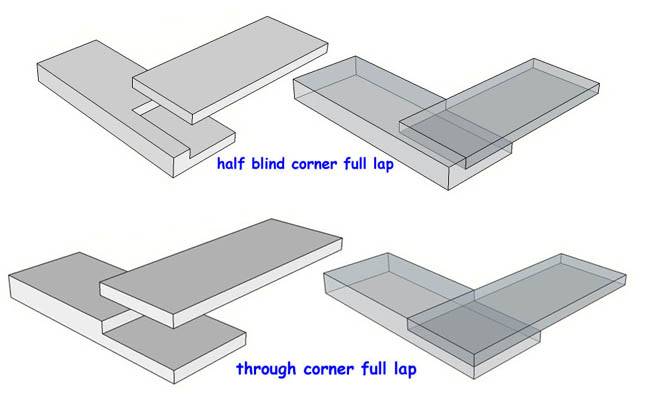

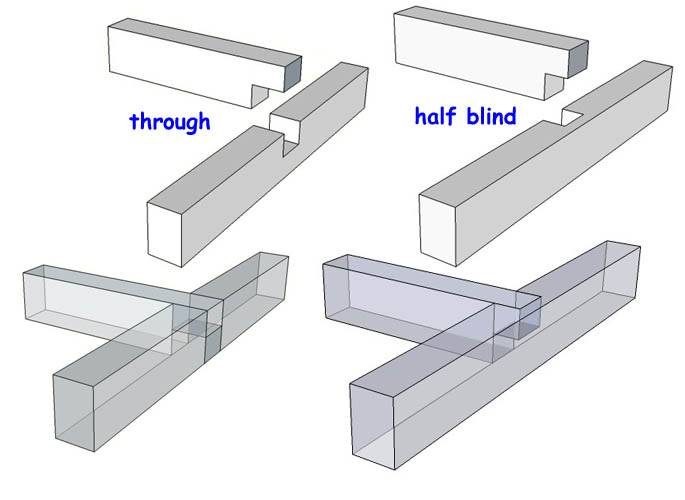

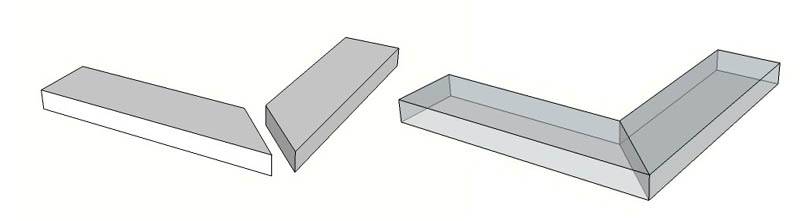

corner full lap --- A full lap joint where the two planks meet at right angles at their ends, rather than one mating into the middle of the other. As can be seen in the examples below, the joint can be half blind or through. Examples:

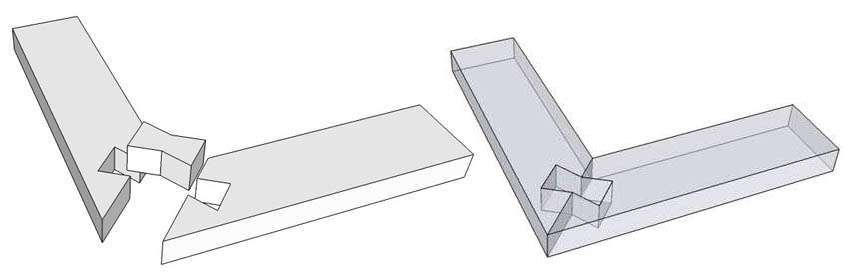

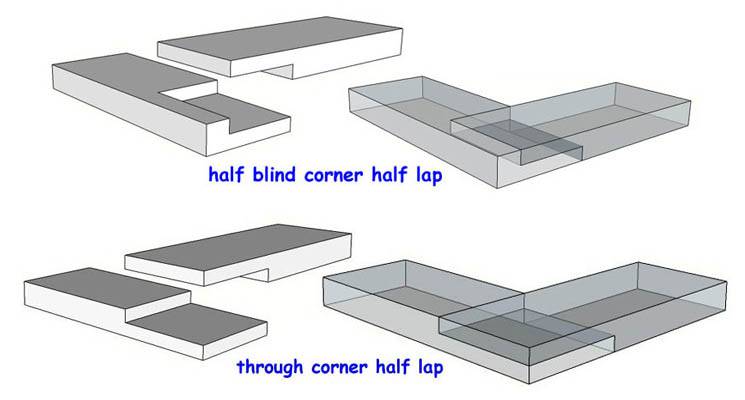

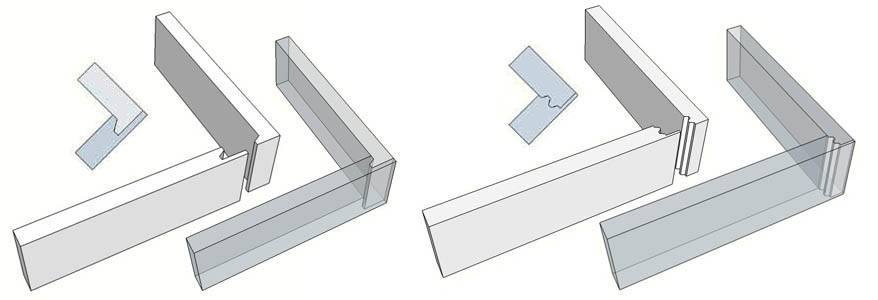

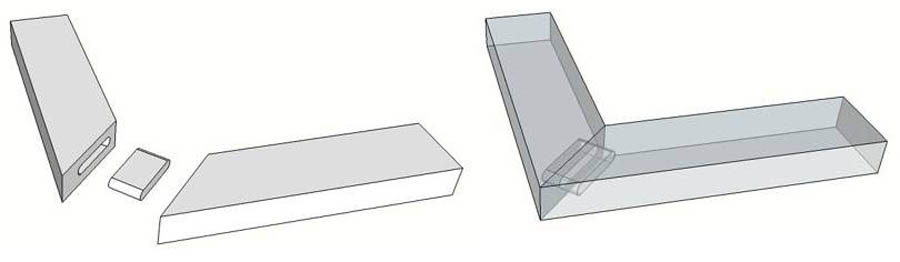

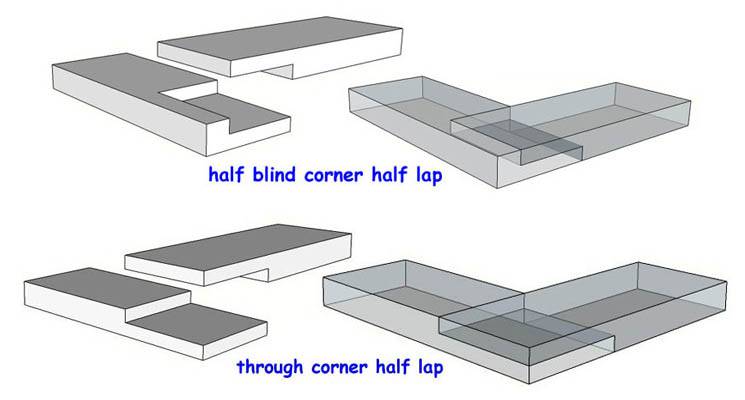

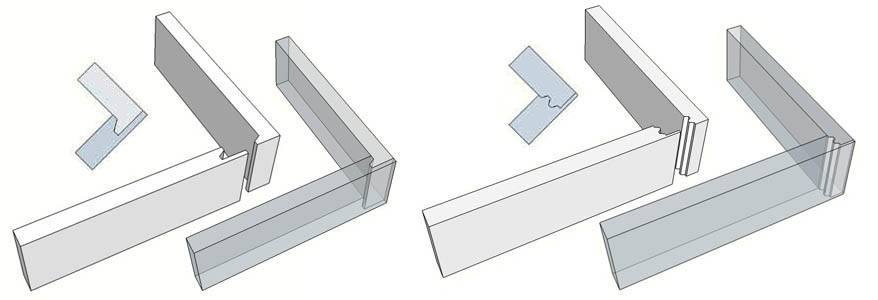

corner half lap --- A half lap joint in which the two planks meet at right angles at their ends rather than one mating into the middle of the other. As can be seen in the examples below, the joint can be half blind or through. Examples:

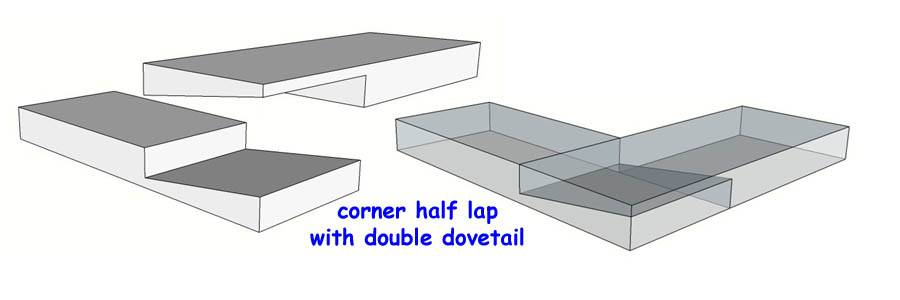

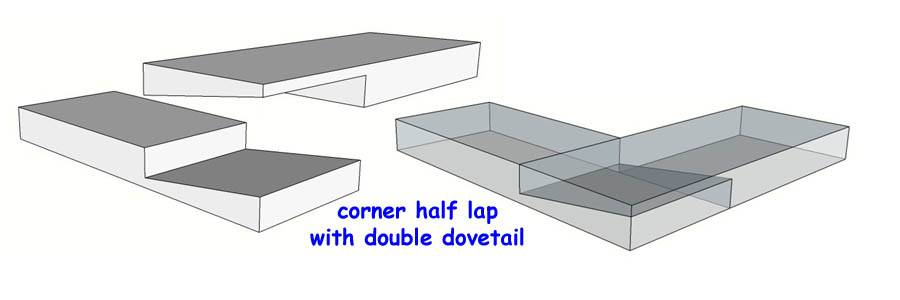

corner half lap with double dovetail --- A corner half lap joint in which the two planks meet at right angles at their ends but where the two laps are both cut at an angle to make them each a half dovetail. This is another one that is best explained by example, so here you go:

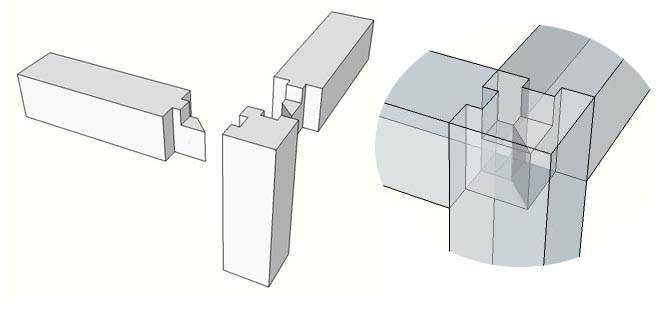

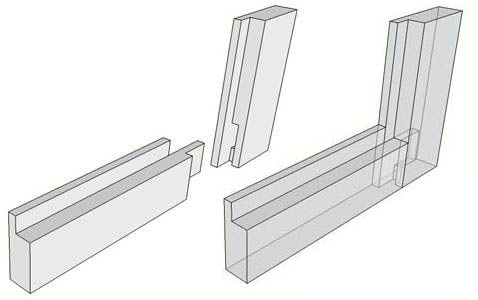

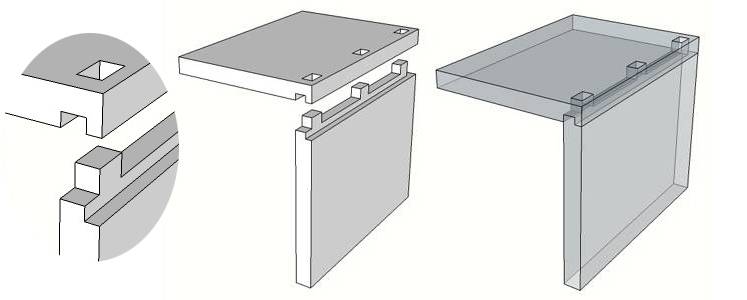

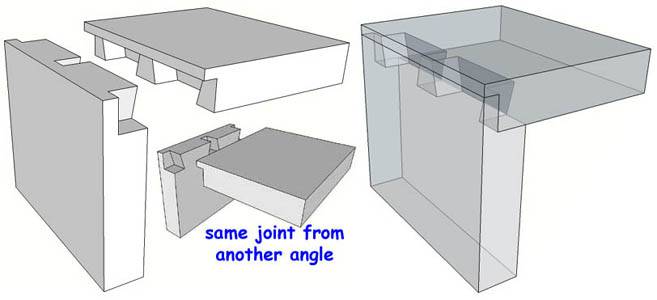

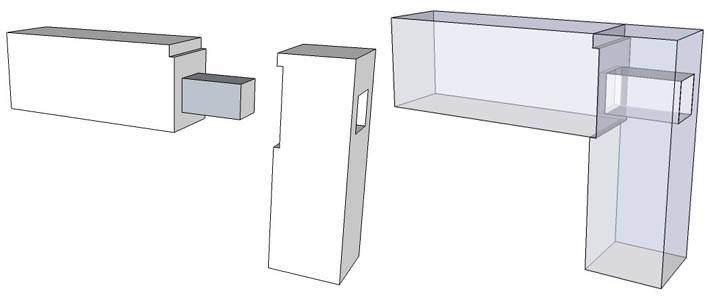

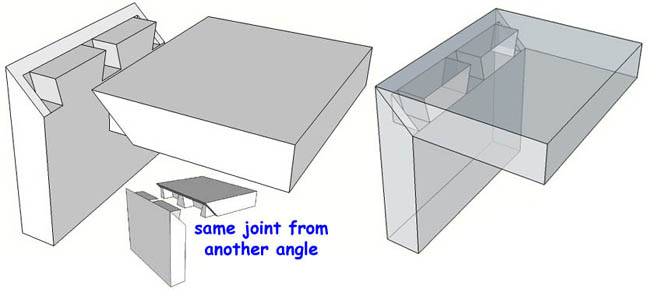

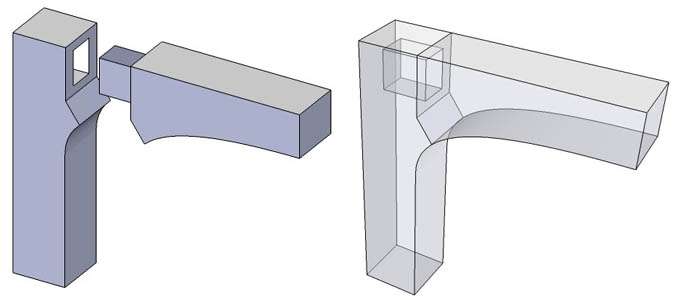

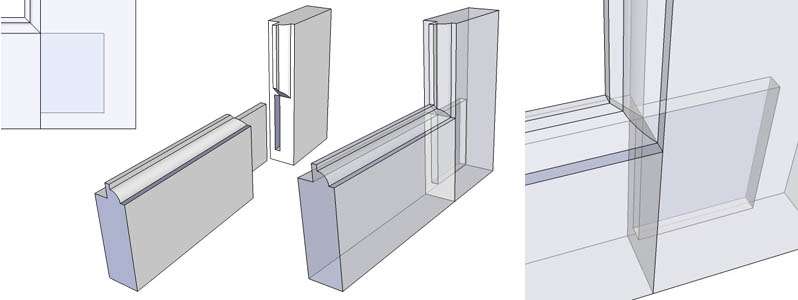

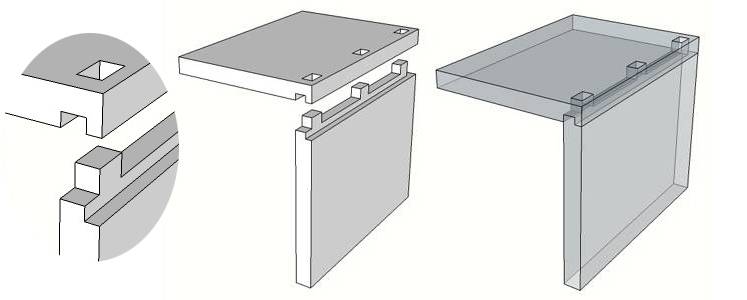

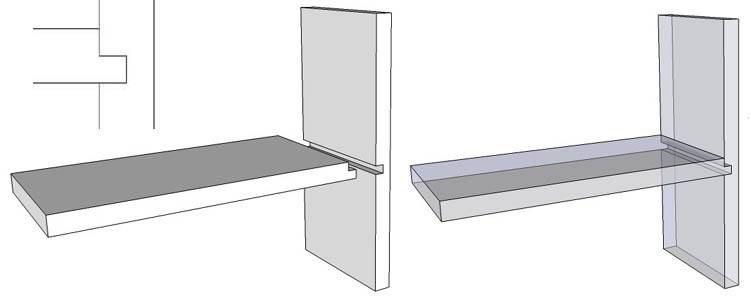

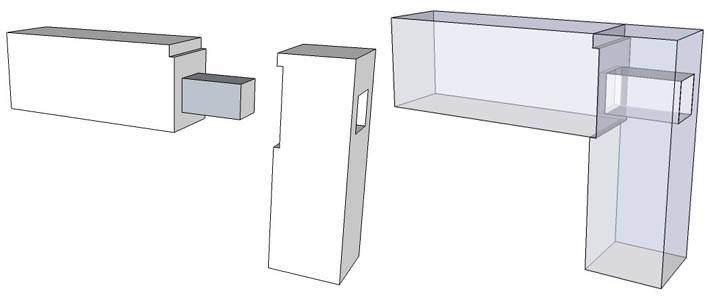

corner tongue and groove --- A joint that can't figure out whether it is a blind mortise and tenon joint, a stopped tongue and groove joint, or a shouldered dado joint and which decided that it was none of the above and damned well needed its own name, by gum! It's very useful for joining table rails to the legs. Best shown by examples, so see below. Not shown is that this kind of joint is normally supported by a corner brace.

crossed edge full lap --- A crossed full lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. Example:

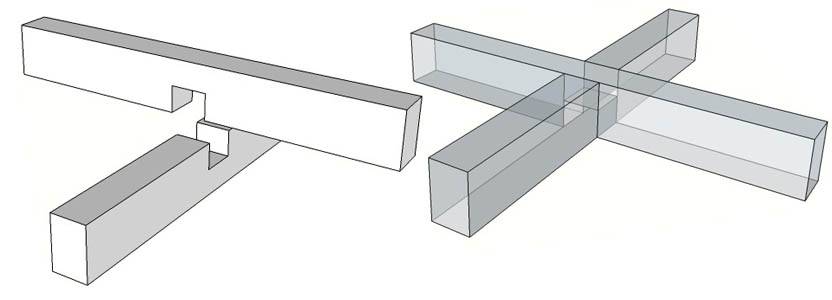

crossed edge half lap --- A crossed half lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. Examples:

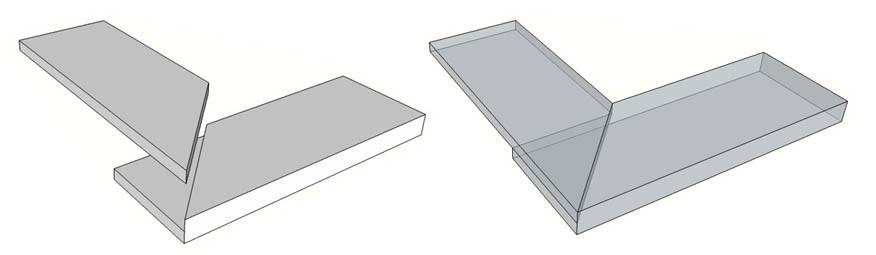

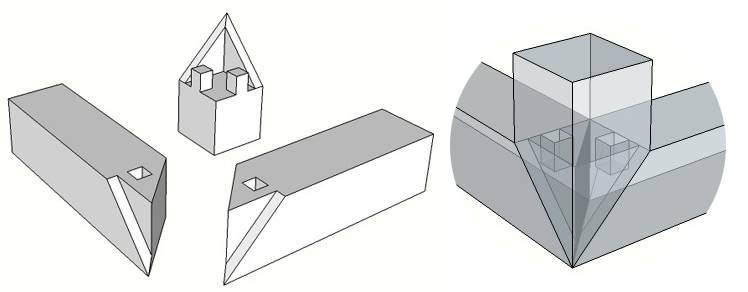

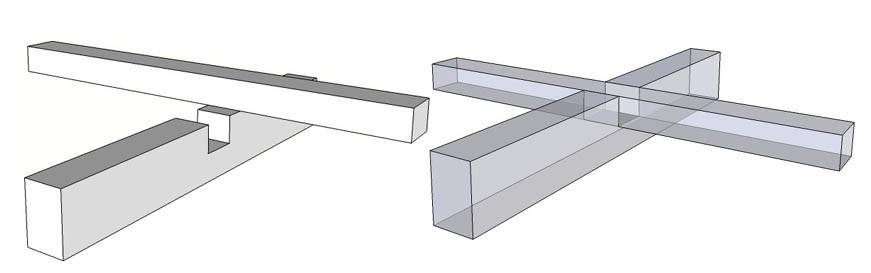

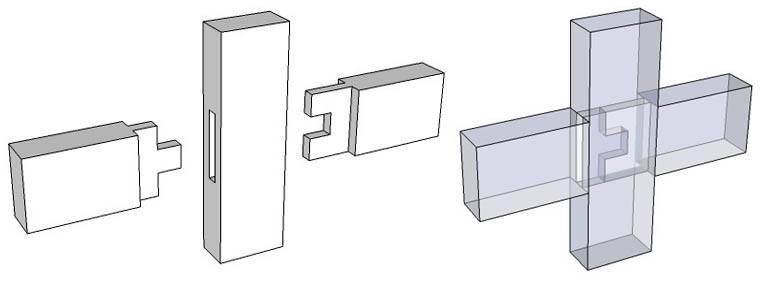

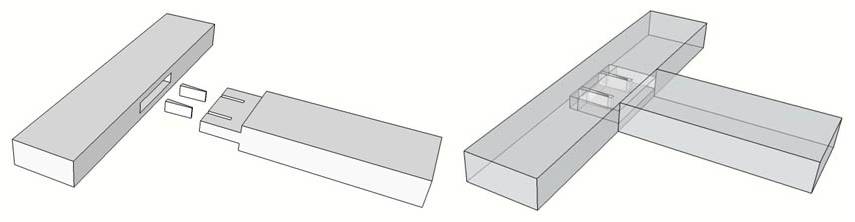

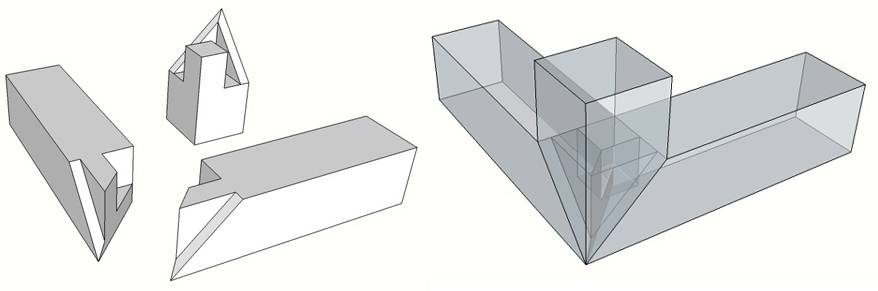

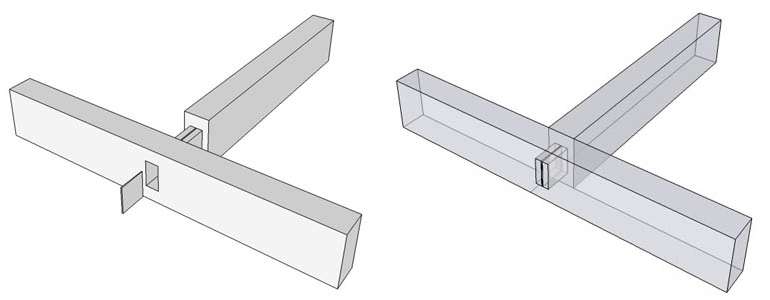

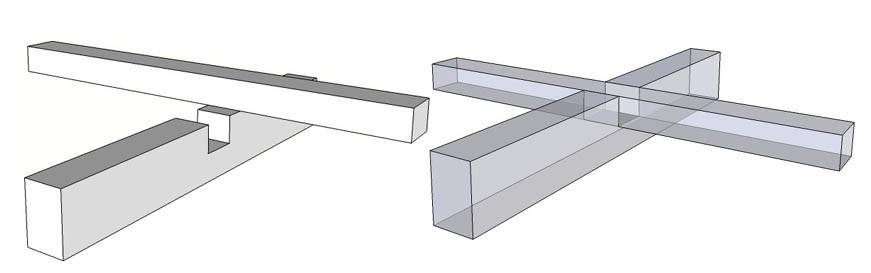

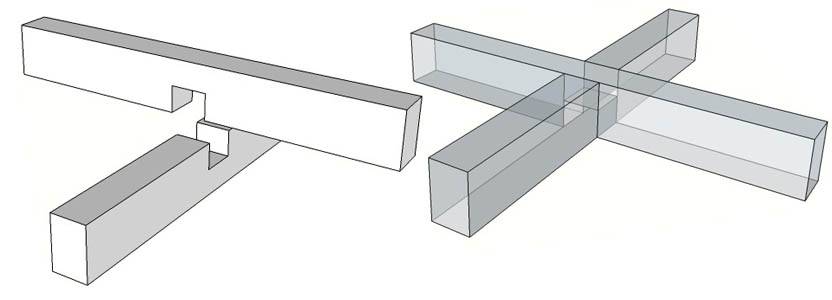

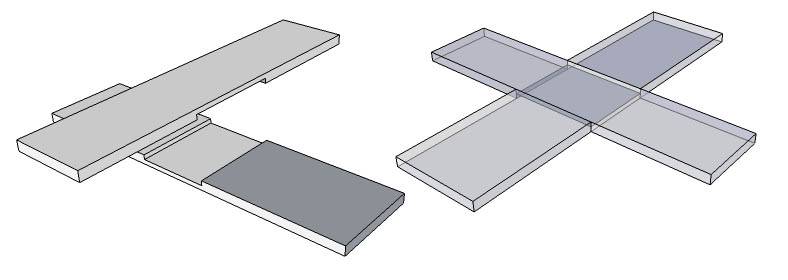

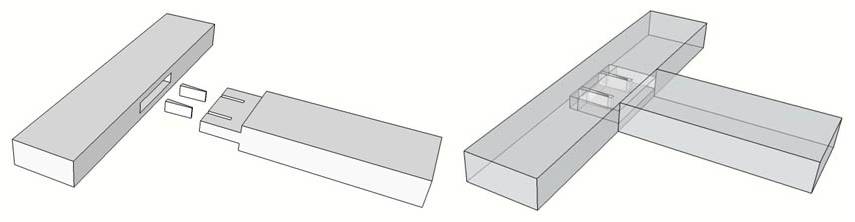

crossed full lap --- A full lap joint where the two planks fully cross each other and are perpendicular to each other. If they cross at an angle other than 90 degrees, then the joint is called an angled full lap. Examples:

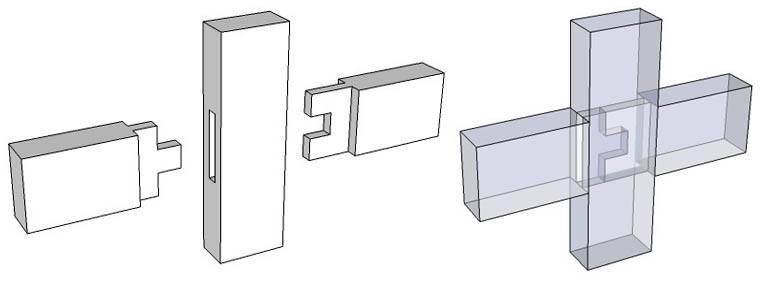

crossed half lap --- A half lap joint where the two planks fully cross each other and are perpendicular to each other. If they cross at an angle other than 90 degrees, then the joint is called an angled half lap. Examples:

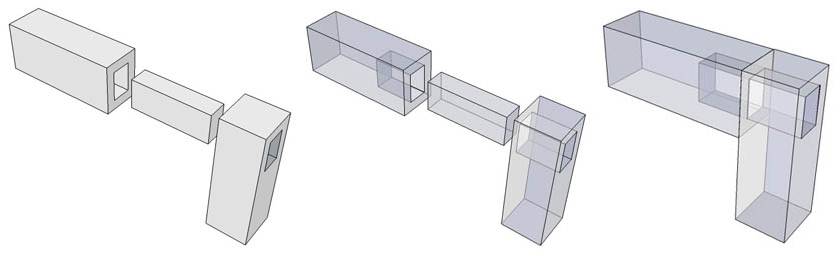

crossed lap joint --- Any lap joint in which two planks (or sticks) fully cross one another. It can be a full lap joint or a half lap joint and it can be a perpendicular crossing or at an angle. Here are some standard crossed lap joints:

crown molding --- Molding that is designed to go over the joint between the walls and the ceiling of a room. Some definitions say that crown molding is any molding along a wall as long as (1) it is at or above eye level and (2) it is the highest molding in the room. Thus chair-rail molding would never be crown molding but a higher decorative strip around the wall would be crown molding if there was no molding above it. Weird, but that's the way I read it. In normal use, I've never seen crown molding used to refer to anything other than the molding placed at the wall/ceiling juncture. Crown molding that goes in the wall/ceiling joint has to be cut with a compound miter cut at the corners. Here are examples of crown molding in various states:

curved dovetail --- This is a primarily decorative variation on the standard through dovetail joint. It is not quite as strong as the standard joint, and it is much more difficult to construct, but the curved dovetail look is quite striking and that's the point. There are "single" and "double" versions. The "single" version (shown below) has a curve from which the tails extend. The "double" version (not illustrated in this glossary) is also curved on the surface from which the pins extend and is an even weaker joint that the single-curved version, but also is correspondingly more striking in appearance. Example:

dado --- (1) the lower section of an interior wall, generally from about waist high (or at the point of a chair rail if there is one) down to the baseboard. The material used to cover this area, if different than the upper part of the wall, is called wainscoting.

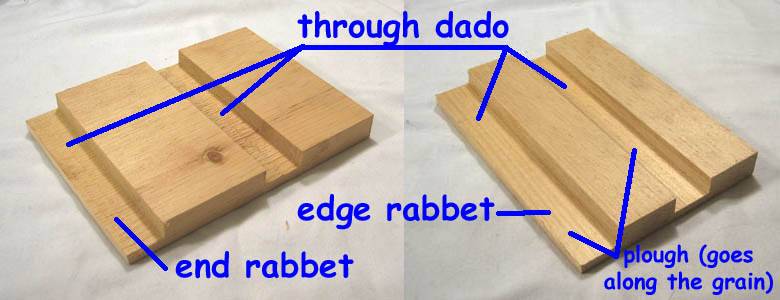

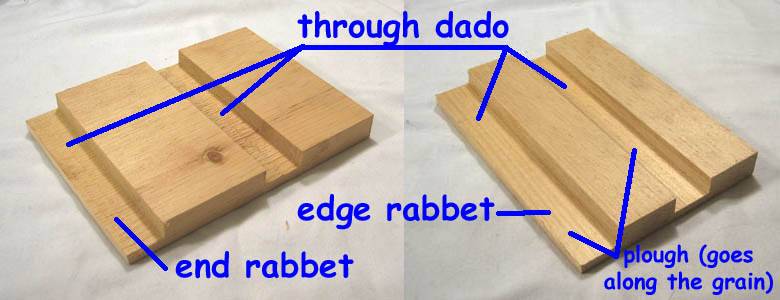

dado --- (2) A rectangular slot cut across the face of a plank, perpendicular to the grain, so that an end or edge of another plank can be inserted to form a load-bearing joint. If the cut is made at the end of a plank, the cut is called a rabbet (or more specifically an "end rabbet" If such a cut is made with (parallel to) the grain it is called a plough cut and if it is made parallel to the grain at the edge of a board, it is called a rabbet (or more specifically an "edge rabbet"). Joints made with dado cuts are classified depending on whether the dado cut goes into both edges (through dado), only one edge (half blind dado), or neither edge (blind dado). For illustrations, see JOINERY GROOVES and those three terms for which the URLs were just given.

Because dado cuts are so commonly done in cabinetry and carpentry, and because they cannot be made with a single pass of a normal saw blade, special blades, called dado cutters have been created and are readily available for the woodworker. These come in two forms, the adjustable dado blade and the stacked head dado cutter. Dado cuts are also commonly made with routers.

dadocutter --- see stacked head dado cutter and adjustable dado blade

dado joint --- A joint made using a dado cut. There are numerous styles, including the following which are illustrated in this glossary. For further explication of joinery grooves, see JOINERY GROOVES.

diagonally wedged mortise and tenon --- A mortise and tenon joint in which the tenon has a wedge that runs diagonally from one corner to the other, thus providing pressure in both directions at once. Personally, I do not see any structural advantage to this joint that would justify the extra complexity of construction, so I have to believe that when it is done, it is done for cosmetic rather than structural reasons. Example:

divided mortise and tenon --- A mortise and tenon joint technique for use when the tenons from two rails both have to go into the same mortise. Rather than just butt them against each other in the middle, the joint is given extra strength and extra glue surface by notching one and putting a projection (sort of a tenon on the tenon) on the other. Example:

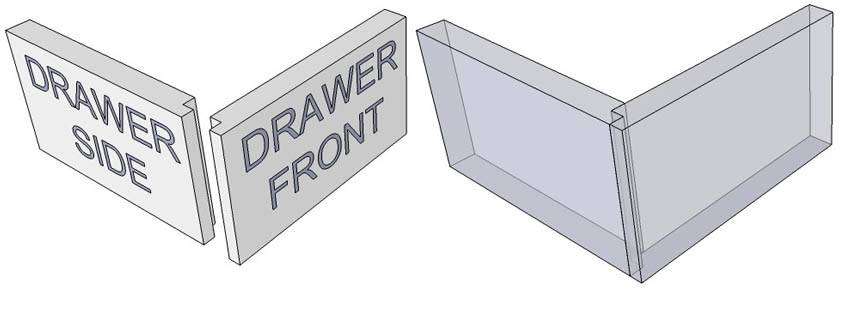

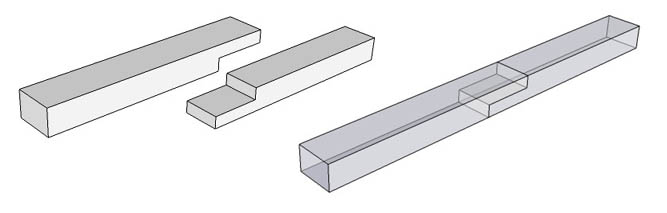

double dado --- A joint that is very similar to the drawer locking joint and which in fact is often used for that purpose. It is a slightly more complicated version of the locking rabbet. In joining the ends of two planks, a dodo is cut in each; best explained by an example, so here you go:

double dovetail half lap --- synonymous with corner half lap with double dovetail

double rabbet joint --- A joint where two edges are both rabbeted and then the two are joined. With no other support this is a very weak joint, only slightly better than an unsupported butt joint. Example:

double shouldered sliding dovetail --- synonymous with sliding dovetail; the only reason for using this particular term would be to specifically distinguish the joint from a single shouldered sliding dovetail

double wedged mortise and tenon --- Although you would, logically, think that this term would refer to a construct exactly like the single wedged mortise and tenon joint but with two wedges instead of one, it actually is used to refer to a tusked mortise and tenon with two wedges instead of one. Note that with two wedges, the outer surface of the wedge cutout is NOT angled as it is in the normal tusked mortise and tenon, but the inner surface is recessed so the wedges exert a pulling force on the piece that accepts them. This joint normally does not use glue; it is a knockdown joint. Example:

dovetail --- (1)[noun] see tail

dovetail --- (2)[noun] see dovetail joint

dovetail --- (3)[verb] To tightly merge two pieces of something together (literally, it means two pieces of wood cut and fitted in a dovetail pattern, but the word has taken on a broader use).

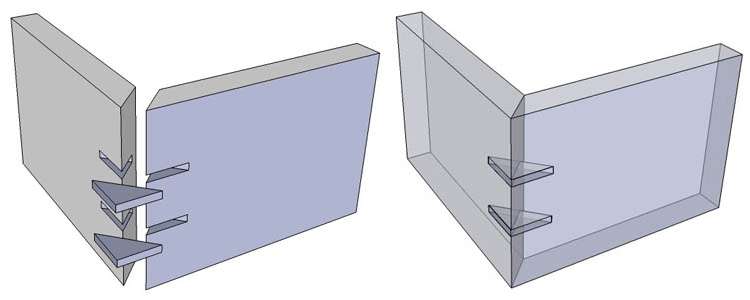

dovetail bridle joint --- A bridle joint with a dovetail prong replacing the more standard rectangular prong. As with the standard bridle joint, and as shown in the examples below, the joint can be half blind or through. Examples:

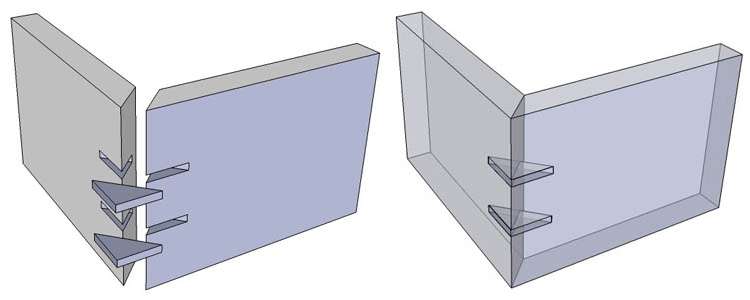

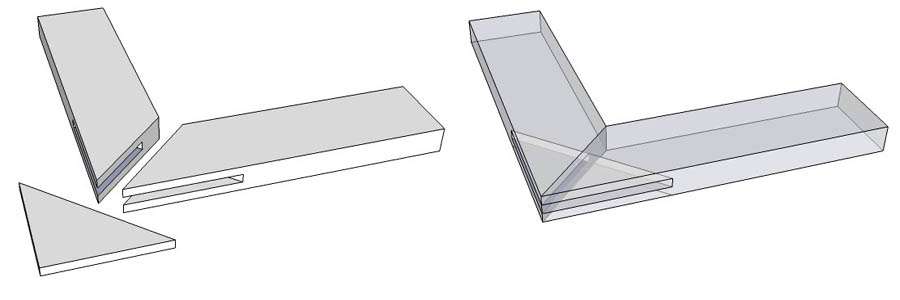

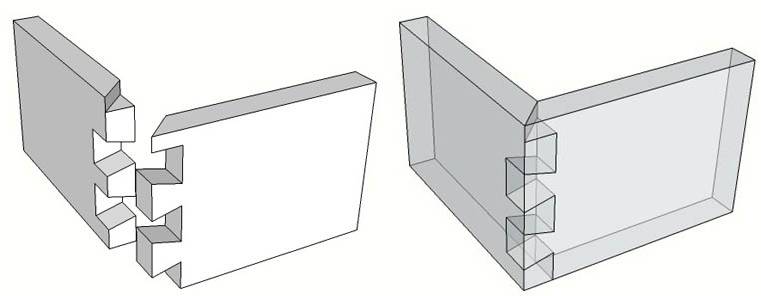

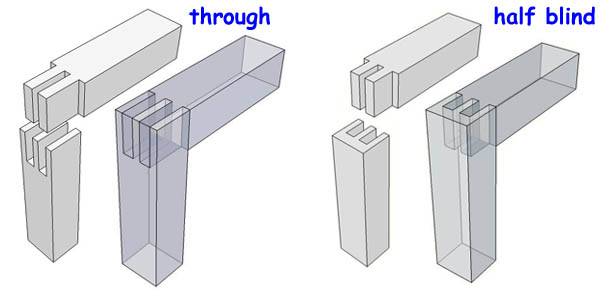

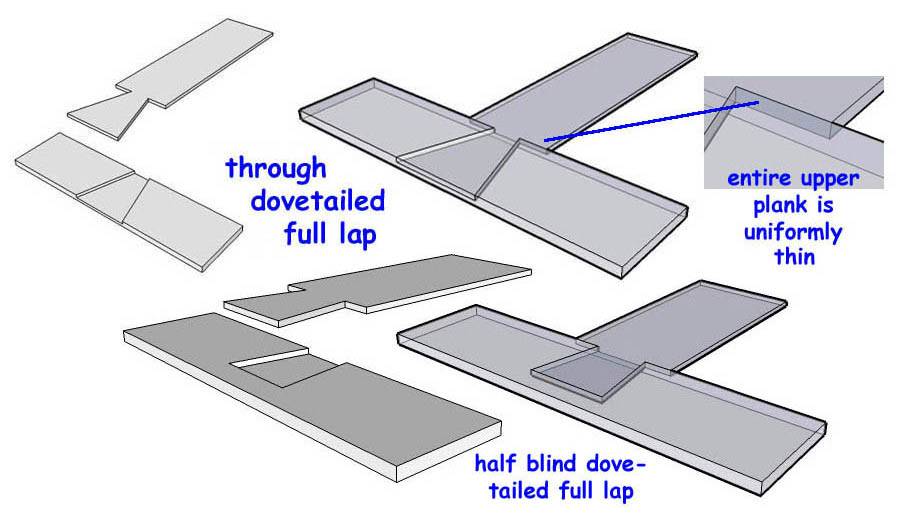

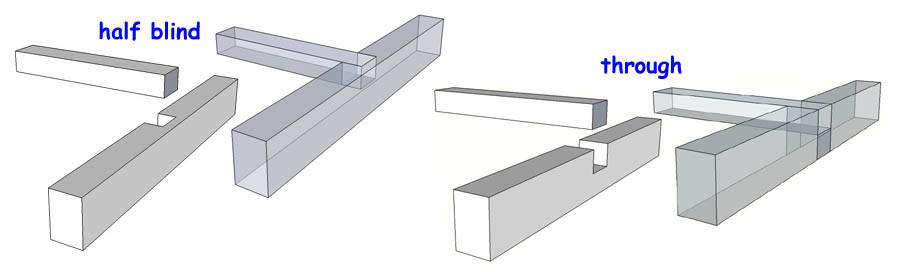

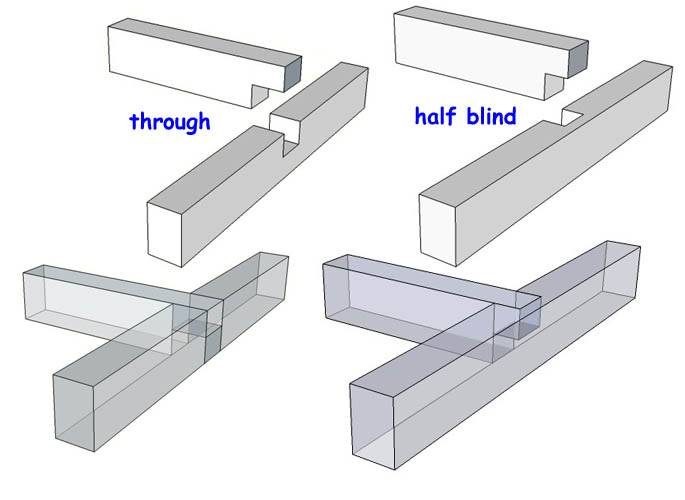

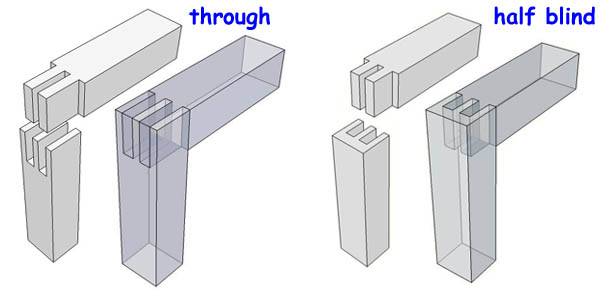

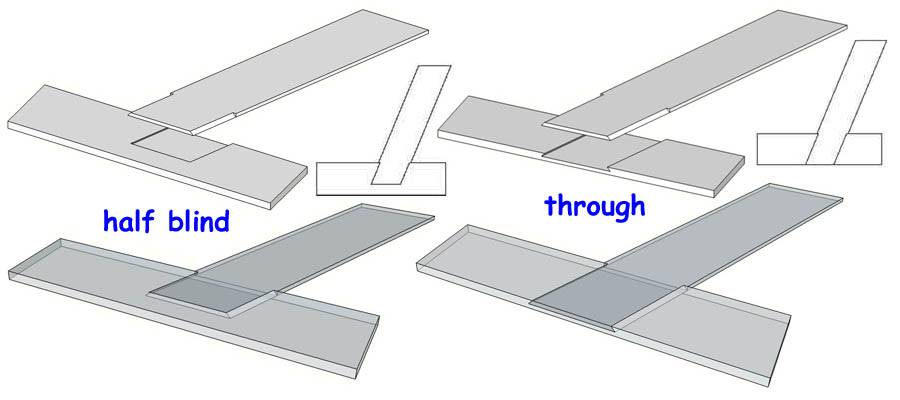

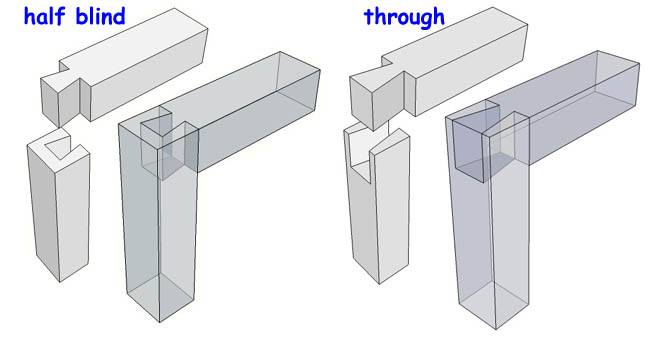

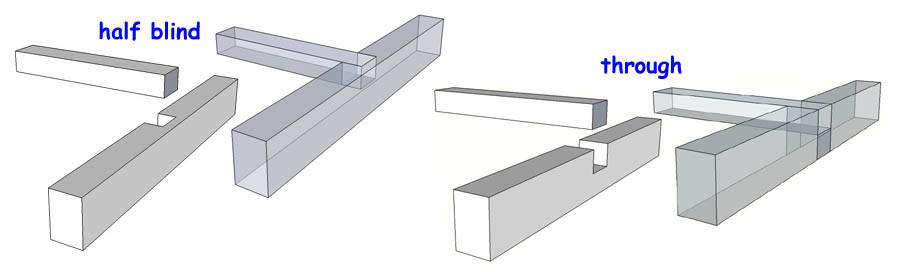

dovetailed full lap --- A full lap joint where the cross piece has a cutout for a dovetail and the mating piece has its end shaped in a single dovetail. As shown in the examples below, the joint can be through or half blind. Compare/contrast to keyed dovetail full lap. Examples:

dovetailed half lap --- A half lap joint where the cross piece has a cutout for a dovetail and the mating piece has its end shaped in a single dovetail. As shown in the examples below, the joint can be through or half blind. Compare/contrast to keyed dovetail half lap. Examples:

dovetail jig --- Although dovetail joints are a rite of passage for cabinet makers, they are very time consuming when done by hand, so commercial jigs have long been available to ease the effort. These are generally highly adjustable and are used with dovetail router bits. Examples:

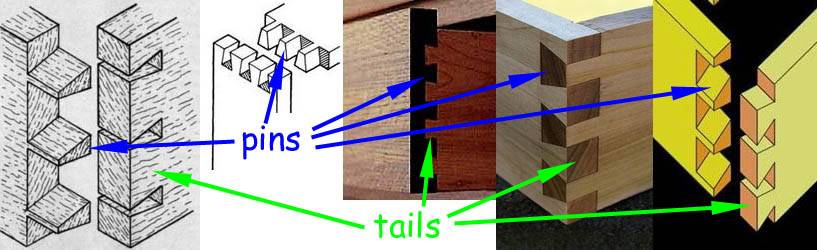

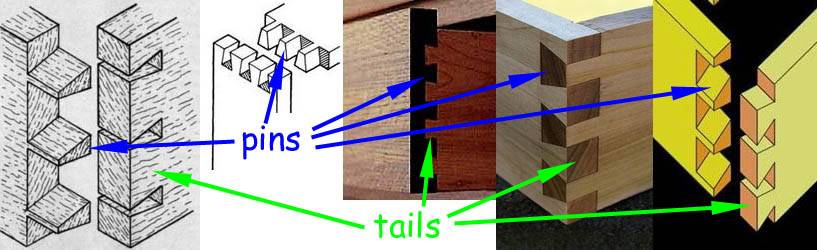

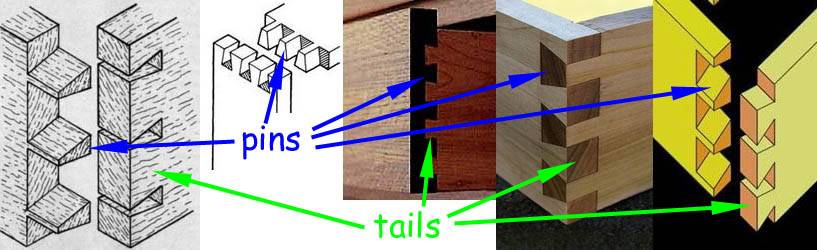

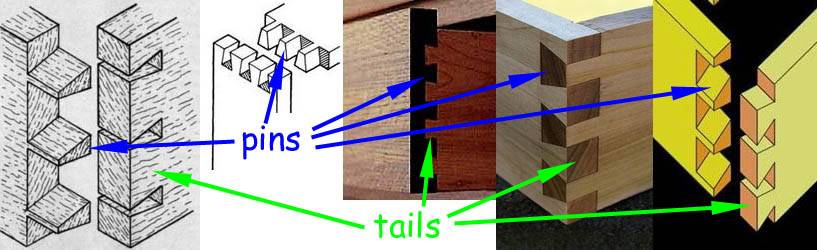

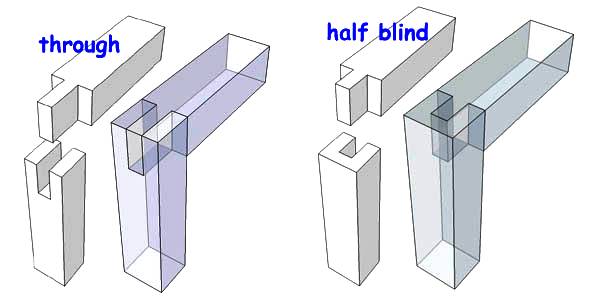

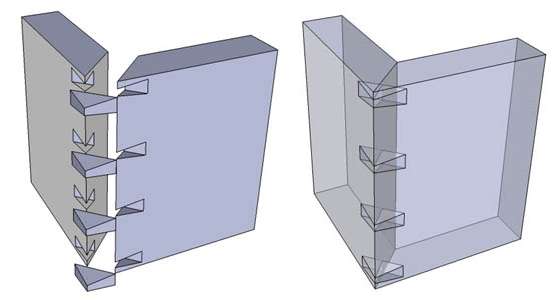

dovetail joint --- A joint formed by creating a dovetail shaped tenon and a corresponding mortise. The size, shape, and angles of dovetail joints are infinite in their variety. They are exceptionally strong and resist separation much better than most joints. They also provide a visual demonstration of woodworking expertise and elegant joinery and are sometimes used for that reason alone. If the cuts show on both of the mating surfaces, that is called a through dovetail joint and if they only show on one surface, that is a half blind dovetail joint and if they are totally hidden from view, that is a blind dovetail. Because the true blind dovetail is a very difficult joint to make and because it is not often used, common usage frequently has the term "blind" dovetail used for what is technically the "half blind" dovetail. More illustrations are given with each term, but here are examples of the three main types of dovetail and a long list of various dovetail joints is given with the term dovetail router bit. See also dovetail jig.

dovetail keyed mitered edge joint --- An edge miter joint that has been strengthened with a key in the shape of a dovetail. This joint is normally made by first making the miter cuts and then holding the two pieces together in a 45-degree jig and passing it over a dovetail router bit to make the mortise and then making a sliding dovetail stick to put in the mortise as the key, which is then cut off flush after the glue dries. In the drawing below, the key is shown in its final size, but in real world construction, it would be cut overlong, slipped in and glued, and then worked to be flush after the glue dried. Example:

dovetail keyed mitered face joint --- A face miter joint that has been strengthened with a key in the shape of a dovetail. This joint is normally made by first making both miter cuts and then holding the two pieces together in a 45-degree jig and passing it over a dovetail router bit to make the mortise and then making a sliding dovetail stick to put in the mortise as the key, which is then cut off flush after the glue dries. In the drawing below, the key is shown in its final size, but in real world construction, it would be cut overlong, slipped in and glued, and then worked to be flush after the glue dried. Example:

dovetail keyed miter joint --- A face miter joint or an edge miter joint with a key in the shape of a dovetail (as opposed to a flat arrow key as is found in the keyed face miter joint and keyed edge miter joint). The two common types are the dovetail keyed mitered edge joint and the dovetail keyed mitered face joint.

dovetail saw --- synonymous with back saw

dovetail scarf --- synonymous with lapped dovetail scarf

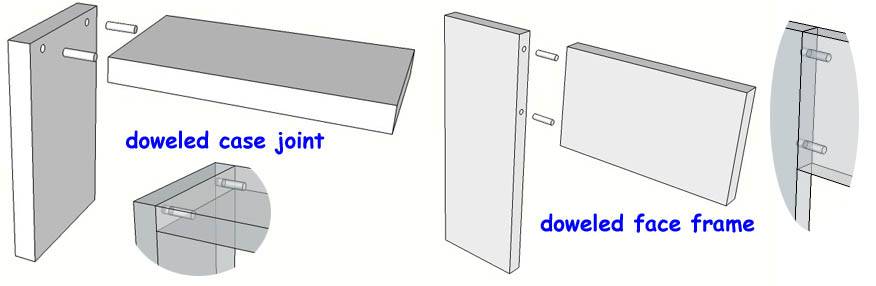

dowel --- A wooden cylinder with a diameter from 1/4" to about 1 1/2" and a length which is generally something like 4 to 6 times the diameter, although there are no specific rules on that. In fact I have not seen any rules at all really, and I have heard the term used for wooden cylinder that was 4 feet long and a foot in diameter, but I think my limited definition is good for general use. Hardware stores sell long dowel rods from which individual dowels can be cut, and craft stores sell pre-cut dowels in various sizes. Precut dowels also come with ridged sides for ease of glue flow around them and also often have tapered ends which greatly eases their entry into tight holes. Another variety of precut dowel pins has spiral grooves around the side. Dowels have numerous uses, most particularly as part of various joints. See also dowel joint, pinned joint and peggedjoint. Examples:

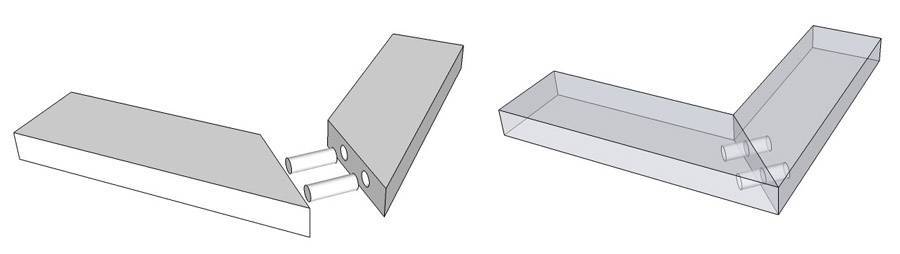

doweled mitered face frame --- A picture-frame type joint with a miter cut (usually at 45 degrees) where the planks meet at the corner and the joint is reinforced with dowels. This joint exemplifies the way that joints with lots of sub-characteristics can be named in different ways; this joint could just as well be called a "doweled face miter joint". Compare/contrast to splined face miter joint and (plain) face miter joint. Examples:

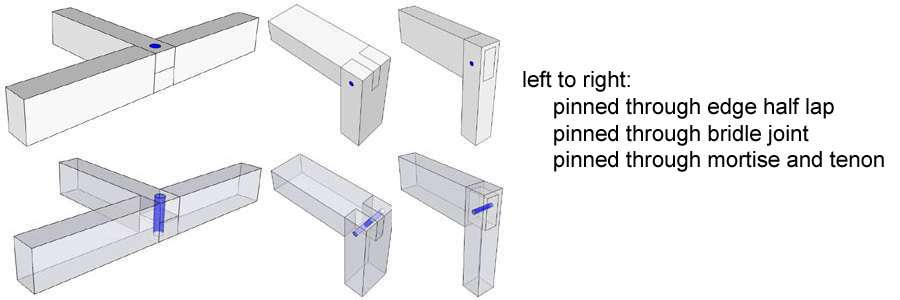

doweled through bridle joint --- A through bridle joint in which the tenon is pinned. Example:

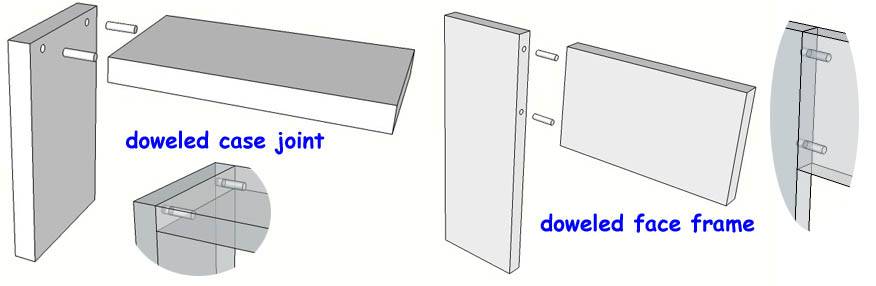

dowel joint --- Any joint where the pieces are joined by dowels running through the joint. This may be in addition to other techniques (such as dado cuts) used in the same joint. That is, "dowel joint" does not specify a particular TYPE of joint but rather the use of dowels to augment any type of joint. There are some definitions that disagree with what I just said and show a dowel joint as being specifically a butt joint with dowels. For those folks, here are a couple of butt joints with dowels:

drawbore tenon --- A technique for providing a little extra tightness to a mortise and tenon joint. It is a pinned tenon but with a slight offset so that the insertion of the pin forces the tenon just slightly more in one or two directions that the opposite directions and helps assure that the joint does not loosen over time. When using this technique, the hole in the tenon has to be drilled when it is NOT in the mortise so that it can be offset by a little. Too much offset can make it hard or even impossible to insert the pin, so this technique requires some care.

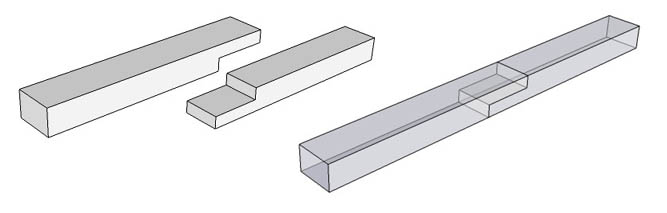

drawer locking joint --- There are numerous styles of joints, all pretty similar, that are called drawer locking joints, and several of them can be constructed with specialty router bits. What they all have in common is that they are used to join the side of a drawer to the front of the drawer and they do so in a way that provides both more glue surface and more mechanical strength than a common butt joint while still leaving the drawer face unblemished (in this regard, they can be considered to be half blind joints. See also double dado and locking rabbet Examples:

drawer stop --- A device that limits the travel of a drawer. The simplest such device is a short strip of wood that is nailed or screwed vertically into the the upper back of a drawer with part above the level of the drawer back and part below. To insert/remove the drawer, the stop can be swiveled down below the level of the drawer back. This term can also refer to a piece of wood at the back of a drawer that prevents the drawer from moving back beyond where the face of the drawer is flush with the face of the cabinet that it is housed in. Example:

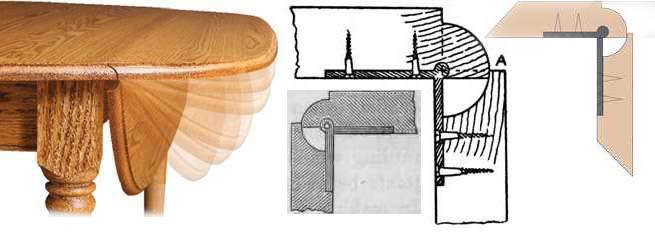

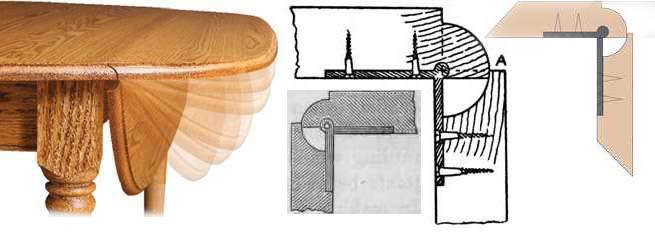

drop leaf --- An extension section on a table top that uses a hinged joint (most commonly in a rule joint) to allow the extension to be vertical at the side of the table (pointing towards the floor) when not in use but horizontal when in use. A drop leaf can be achieved by just face mounting a butt hinge on the bottom of table and the bottom of the butt jointed leaf, but a rule joint looks much nicer and is considered a more elegant look. Example:

dry joint --- A joint that does not use any adhesive but rather is either a pressure fit or uses nails or screws. Sometimes the term is used to mean a knockdown joint, which of course doesn't use glue OR fasteners. The term is also applied a joint that WILL use glue and/or fasteners but which is at the moment just being fitted to make sure the wood edges meet accurately.

dutchman --- synonymous with butterfly

edge banding --- [noun] Veneer strips used to cover the exposed edges of panel products such as plywood or other composite material edges (for example, on face frames). Such veneer is usually available in rolls and is available both pre-glued and unglued. Wood strips, generally 1/4" and thicker, used for the same purpose, are sometimes also called edge banding, but should more properly be called edging.

edge banding --- [verb] The process of putting on the material as described above.

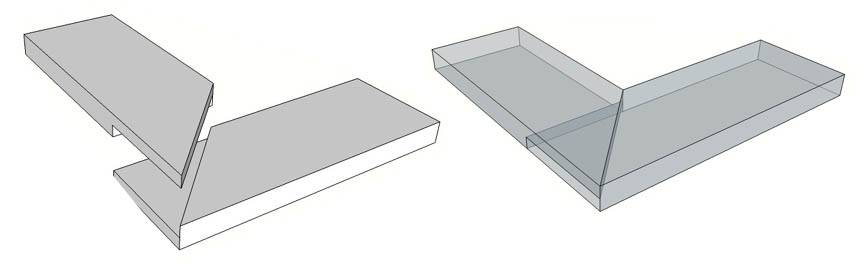

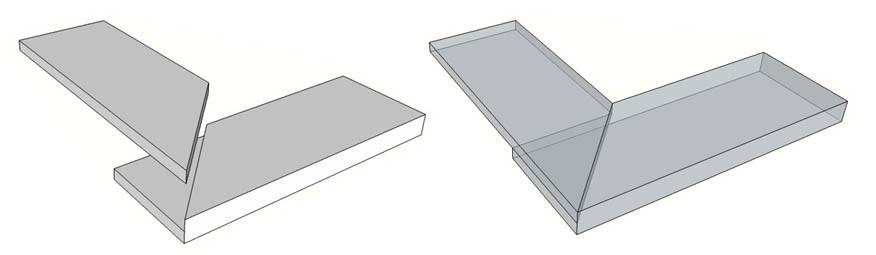

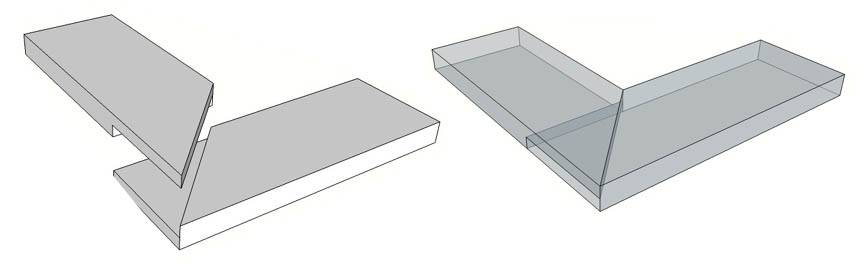

edge full lap --- A full lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. As can be seen in the examples below, the joint can be half blind or through. Examples:

edge half lap --- A half lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. As can be seen in the examples below, the joint can be half blind or through. Examples:

edge joint --- A joint made by bonding two pieces of wood together edge-to-edge, commonly by gluing. The joints may be made by gluing two squared edges as in a plain edge joint or by using machined joints of various kinds (e.g. tongued and grooved). A plain edge joint (with just flat abutted edges) is also called a butt joint.

edge miter cut --- see miter cut

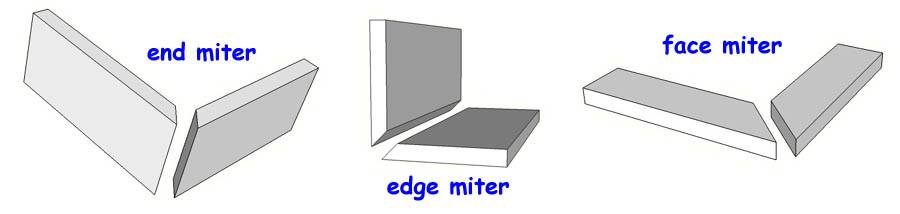

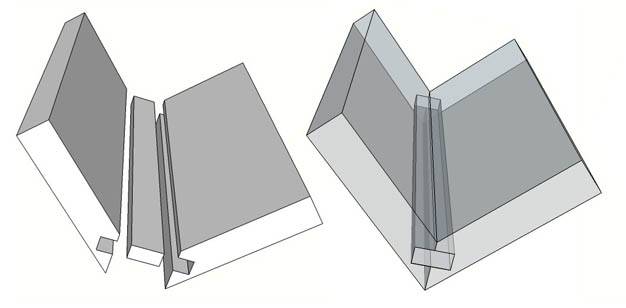

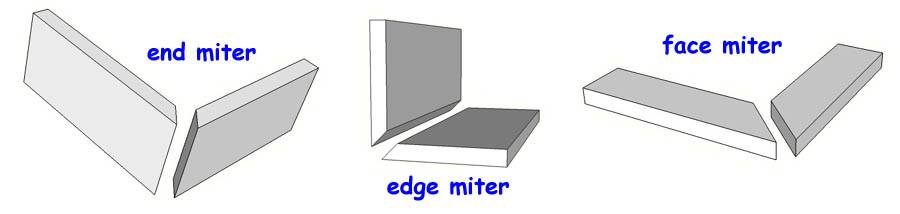

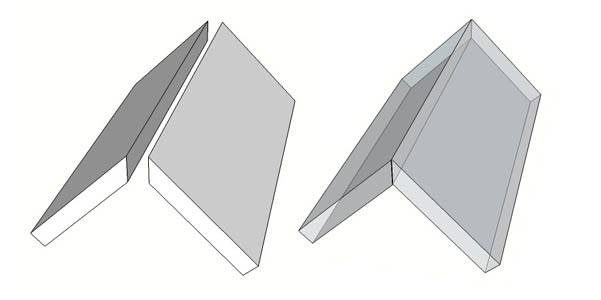

edge miter joint --- A joint where the edge of one plank meets the edge of another plank at 90 degrees and each edge is cut with a (normally 45 degree) miter cut. Compare/contrast to edge rabbet. If reinforced with a spline, then the joint is a splined edge miter joint. Examples:

edge rabbet --- see rabbet

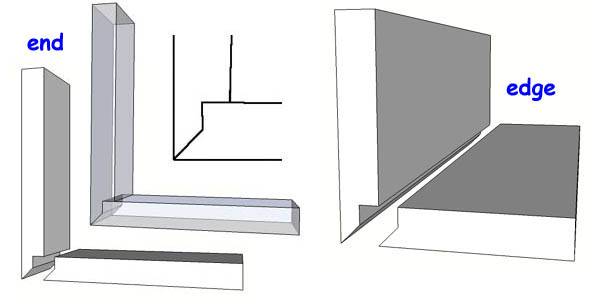

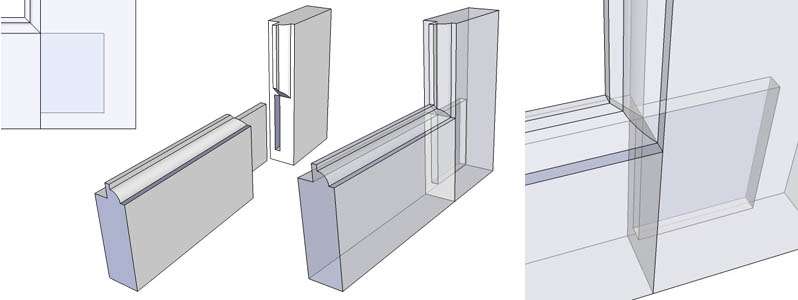

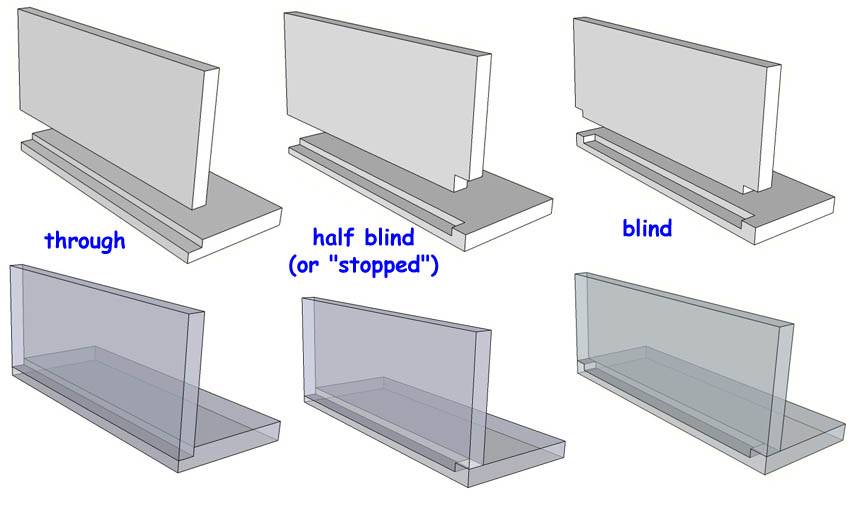

edge rabbet joint --- A joint that puts together two planks along their side edges, using a rabbet cut. As can be seen in the examples below, the joint can be blind, half blind, or through. Examples:

edgesplinejoint --- synonymous with splined edge miter joint

edge to edge butt joint --- see butt joint

end miter cut --- see miter cut

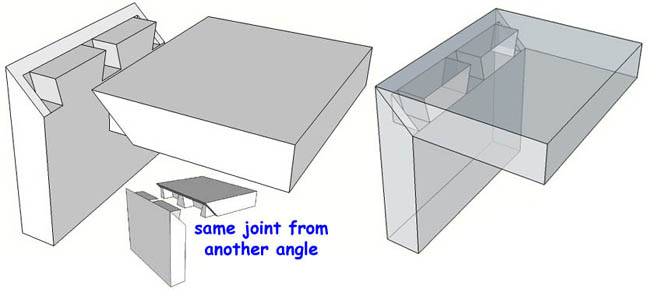

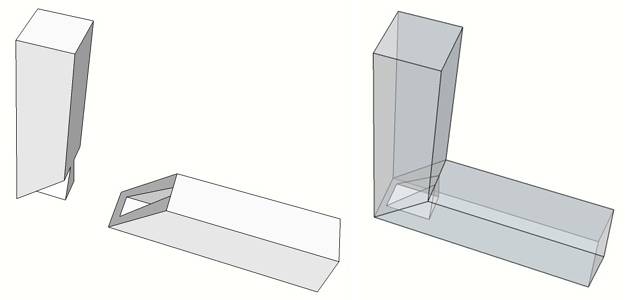

end miter joint --- A drawer type joint, where the end of one plank meets the face of another plank and the two are both cut with a (normally 45 degree) miter cut. Compare/contrast to case joint and end rabbet. Examples:

end rabbet --- see rabbet

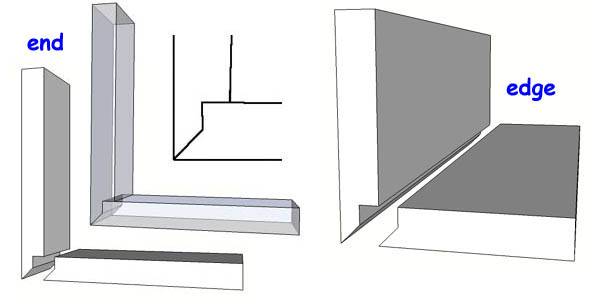

end rabbet joint --- A joint that puts together two planks along their ends, using a rabbet cut. As can be seen in the examples below, the joint can be blind, half blind, or through. Examples:

end to edge butt joint --- see butt joint

end to end butt joint --- see butt joint

end to face butt joint --- see butt joint

end wedged mortise and tenon --- This is like a standard through mortise and tenon except that the mortise is reverse tapered (that is, it is tapered to be wider at the EXIT of the tenon than at the entrance, and then wedges are put in above and below the tenon. This provides a holding force on the tenon that will make the joint stronger than glue alone. Examples:

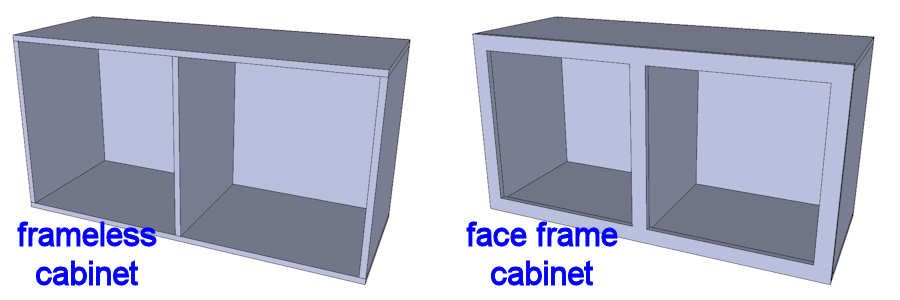

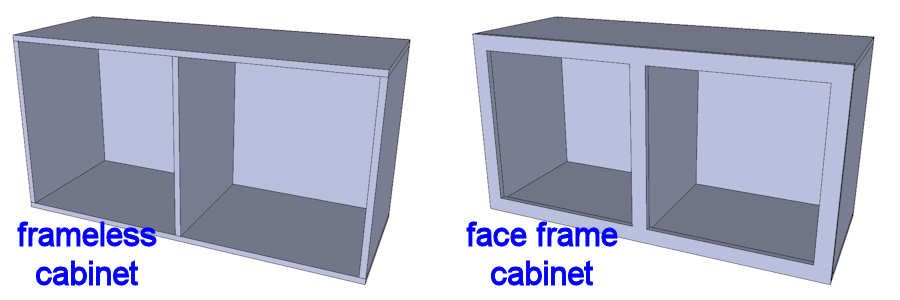

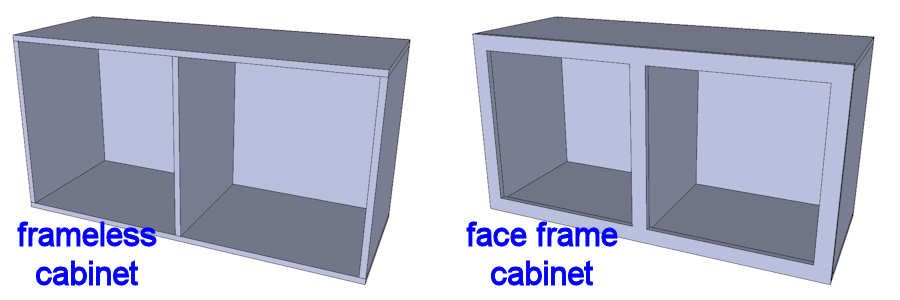

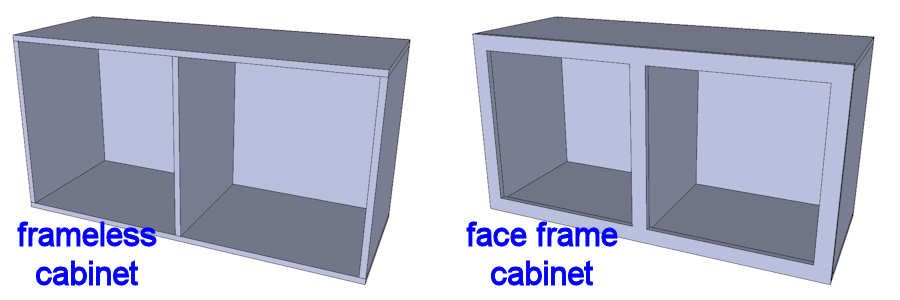

face frame --- A flat frame attached to the front of a cabinet, usually to conceal the exposed edges of the plywood at the front of the carcass and to give extra surface on which to mount doors. The face frame is generally made up of rails and stiles and has large openings for drawers, doors, etc. Examples:

face frame cabinet --- A cabinet that has a face frame. Compare/contrast to frameless cabinet. Example:

face frame door --- A door that is attached to a face frame cabinet. There are several chacteristics that distinguish types of face frame doors as listed directly below. Compare/contrast to frameless door.

- beaded inset --- goes flush with the face frame and the face frame has a bead around the door opening

- flush --- same as inset

- full overlay --- fully covers the face frame

- half overlay --- same as a full overlay except with matching doors that close next to each other, and where they close they each cover only half of the underlying face frame. For an illustration, see the first three images in the (partial) overlay composit below

- inset --- leaves the frame fully exposed and is flush with it

- overlay --- partially overlaps the frame, leaving some of it exposed.

- partial overlay --- same as overlay

- standard overlay --- same as overlay

- standard reveal --- same as overlay

Examples of the various types (I note that several of the insert and beaded insert doors seem to have been photographed before installation of the door pull knobs --- overlay doors don't need knobs because you can get your finger behind them or at least up against the edge but inset doors need a knob):

inset face frame doors

beaded inset face frame doors

full overlay face frame doors

(partial) overlay face frame doors

face keyed miter joint --- A face miter joint that has keys on one or both faces (that is, the front and back); the example below shows both. Not to be confused with the very similar keyed face miter joint which has a single key inside the planks. Example:

face miter cut --- see miter cut

face miter joint --- A picture-frame type joint with a miter cut (usually at 45 degrees) where the planks meet at the corner. The joint can be just glued, or it could be reinforced with biscuits or dowels or a spline. Compare/contrast to frame joint and edge miter joint and also see splined face miter joint, butterfly keyed mitered frame joint, and doweled mitered face frame. Examples:

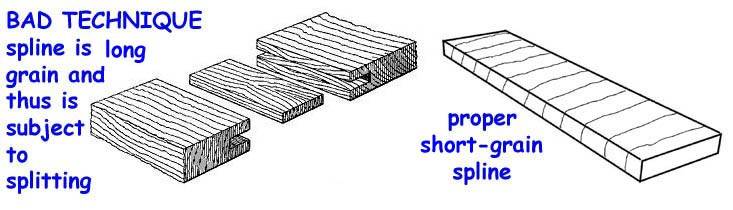

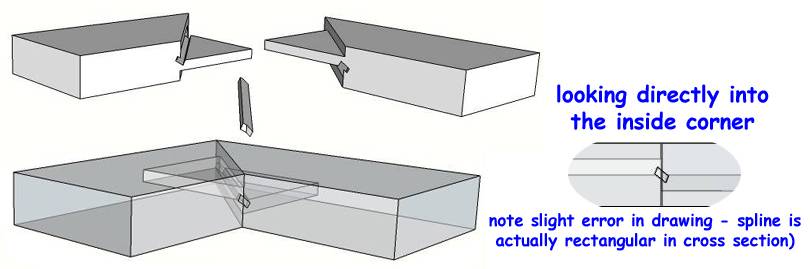

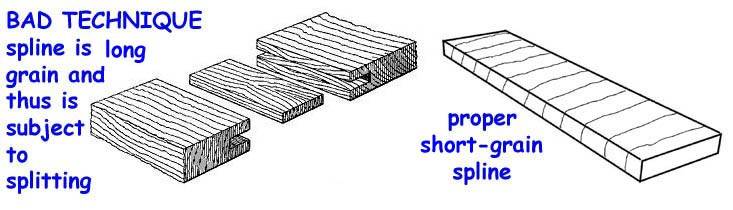

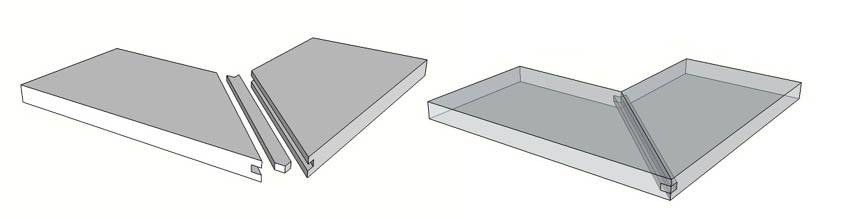

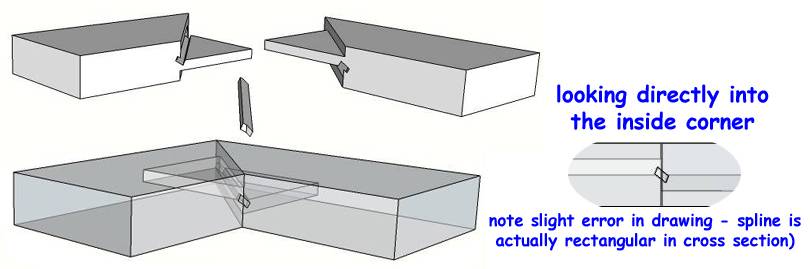

feather spline --- A joint where a spline is put inside a mitered corner where the mating planks are flat and the spline goes in the edge of each. When looked at by itself, such a spline has the stereotypical shape of a feather (actually, more of an arrowhead shape, but that's just being picky), thus this particular type of spline is called a feather spline and the joint is called a feather spline joint. The joint is also called a keyed miter joint and there is an illustration with that term.

finger joint --- This term normally is synonymous with tapered finger joint. In fact, most folks just call the tapered finger joint a finger joint. BUT ... some people use the term finger joint to mean what is normally called a box joint.

finish carpentry --- The detail woodwork that will be visible when a project is completed. This includes door and window frames, moldings, base trims, chair rails, etc. Compare/contrast to framing.

flat spline joint --- synonymous with splined face miter joint

floating --- In woodworking this carries the connotation of "not fixed" (that is, not nailed / glued / screwed). Two places where it is used in particular are (1) in rail and stile construction where a panel sits loosely inside the rails and stiles so that movement caused by changes in relative humidity will not cause the wood to crack, and (2) in loose mortise and tenon where the meaning is slightly different and refers to the fact that the floating (aka "loose") tenon is not an integral part of one of the elements the way it normally is.

floating tenon --- synonymous with loose tenon

flush --- In woodworking, this word is used in its sense of "level with"; used to describe a situation where a the surfaces of two adjacent objects, or portions of an object, line up perfectly with each other. Compare/contrast to proud (above) and shy (below).

flush face frame door --- see face frame door

folding wedges --- This refers to a construct that uses two opposing wedges instead of one, for example in the "tusked mortise and tenon with folding wedges" joint. I have no idea how the term "folding" got into the name (I would called it "paired wedges" but as always, I don't get to make the rules, I just report). Typically, the two wedges will fit together in a way that presents parallel outer surfaces in the mortise. Folding wedges are generally, used in knockdown joints but not necessarily so (that is, a joint that uses folding wedges does not HAVE to be a knockdown joint). See tusked mortise and tenon with folding wedges for an illustration.

foxtail wedged mortise and tenon --- see foxtail wedging

foxtail wedging --- The technique of using one or more wooden wedges to spread a tenon in a blind mortise and tenon. This is a bit tricky since if the wedge is too thin, it does no good and if it is too thick the two pieces will not mate fully. Unlike in a through wedged mortise and tenon, you can't just jam the wedge in and then cut/sand off any excess. Examples:

frame joinery --- There are fundamentally two types of joinery: frame joinery and carcass joinery. Frame joinery is the art/science of constructing joints for frames (as opposed to carcasses). Frame joinery is used for doors, picture frames, face frames and so forth. Most joint types can be used for both frames and cases, but the types that are associated mostly with frames include lap joints, bridle joints, mortise and tenon, and tongue and groove.

frame joint --- Generally, a frame joint is any joint used in the construction of any type of frame (as opposed to carcass) but more specifically, the term is used to refer to a picture-frame style joint where the end of one plank is butted up against the edge of another plank to form a corner. The joint can be just glued, or it could be reinforced with biscuits, dowels, or splines. It can be a butt joint or mitered. Examples:

frameless cabinet --- A cabinet that does not have a face frame and that therefore has the edges of the carcass exposed when the door is open. Compare/contrast to face frame cabinet. Example:

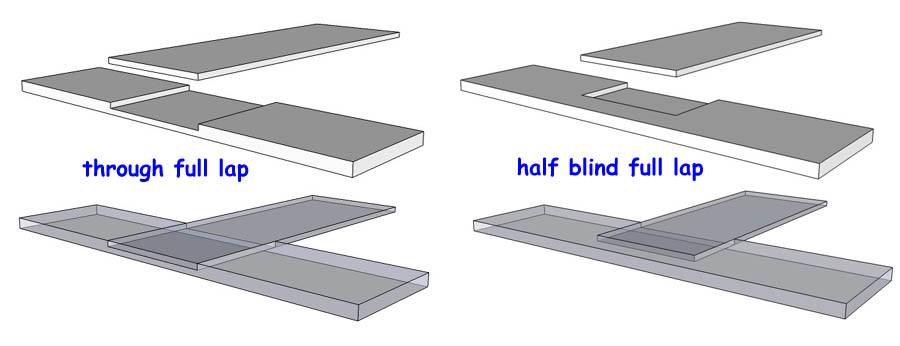

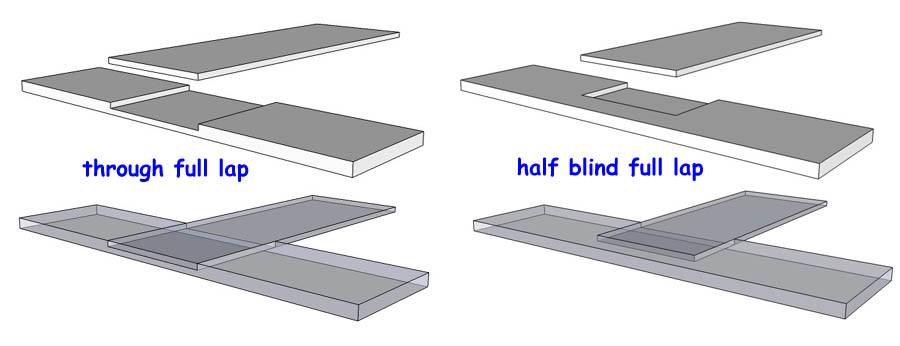

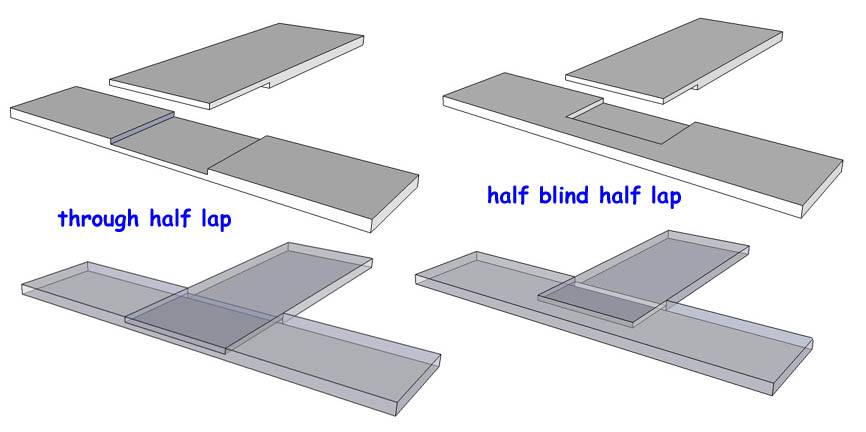

full lap joint --- A joint style in which two planks cross each other, fully or partially, and grooves are cut in one, with the other being the thickness of that groove, so that their face surfaces are flush when they mate. There are numerous types of full lap joints, depending on whether the planks cross totally or partially, whether they cross at right angles or some other angle, whether the cross in the middle or at the corners, and so forth. Many types of full lap joints are discussed and illustrated in this glossary under the terms listed below. The basic forms are illustrated directly below the list. Compare/contrast to half lap joint.

full overlay face frame door --- see face frame door

glue joint --- (1) A joint that uses adhesive instead of nails or screws. Compare/contrast to dry joint.

glue joint --- (2) The location at which two objects are held together with glue.

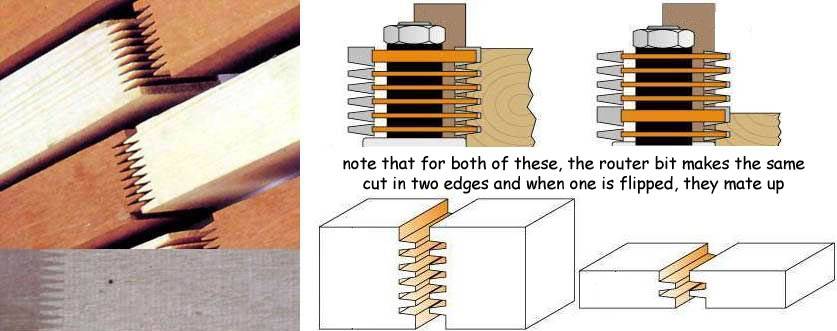

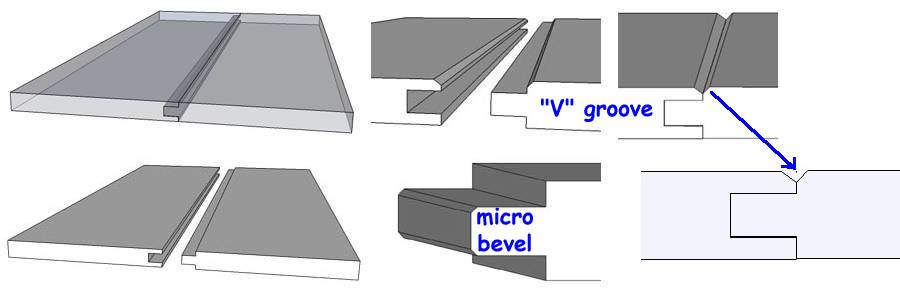

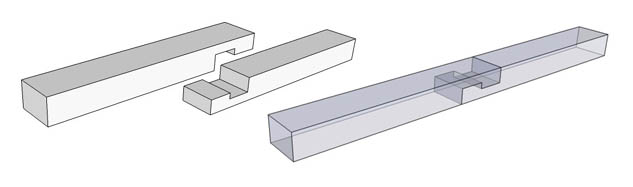

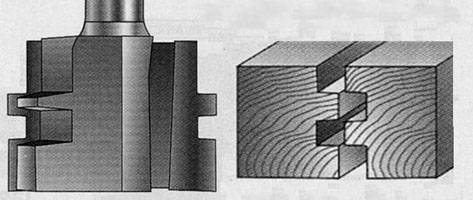

glue joint --- (3) Although any joint that is fastened with glue can be called a glue joint, the term more specifically means a joint that has been given more surface area by some manner of cutting or routing, so as to give the glue more holding area. There are numerous router bits that serve this purpose; here is one example, and if you look carefully you will see that this bit has a characteristic that is typical of such bits which is that if you line up the bit and the plank just right, you can make both passes on the same bit. That is, you cut two planks on their edges and then you flip one of them over and it fits into the other with both faces flush. In addition to providing more surface area for the glue, this kind of routing also provides greatly added shear strength at the joint.

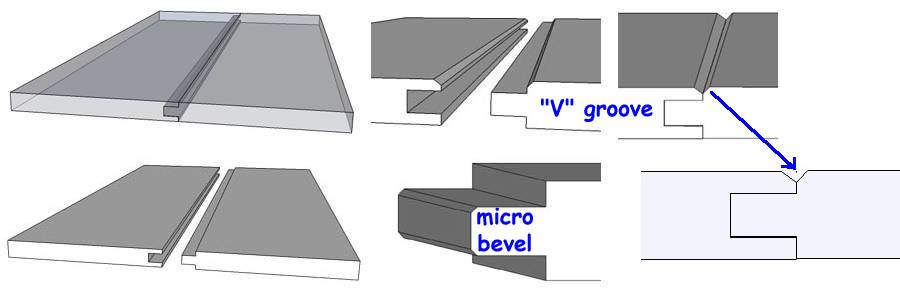

groove --- (1)[noun] A long narrow channel cut in wood. In wood carving, this might be any cross section including "V" shaped, "U" shaped, rectangular, and others; in wood joint terms, it has a rectangular cross section and is also called a dado, and if it is cut parallel to the grain, it can also be called a plough cut, and if cut along the edge or end, it is called a rabbet. For a full explication of joinery groove terms, see JOINERY GROOVES. See also tongue and groove.

groove --- (2)[noun] A surface treatment on a textured plywood panel in which a series of narrow, parallel channels, usually "V" shaped, are cut into the surface so that the panel looks like a series of mated planks.

groove --- (3)[verb] To cut a channel of the type(s) described in (1) and (2) above.

half blind --- see half blind joint

half blind angled dovetailed full lap --- see angled dovetailed full lap

half blind angled dovetailed half lap --- see angled dovetailed half lap

half blind angled full lap --- see angled full lap

half blind angled half lap --- see angled half lap

half blind angled keyed dovetail full lap --- see angled keyed dovetail full lap

half blind angled keyed dovetail half lap --- see angled keyed dovetail half lap

half blind bridle joint --- see bridle joint

half blind corner full lap --- see corner full lap

half blind corner half lap --- see corner full lap

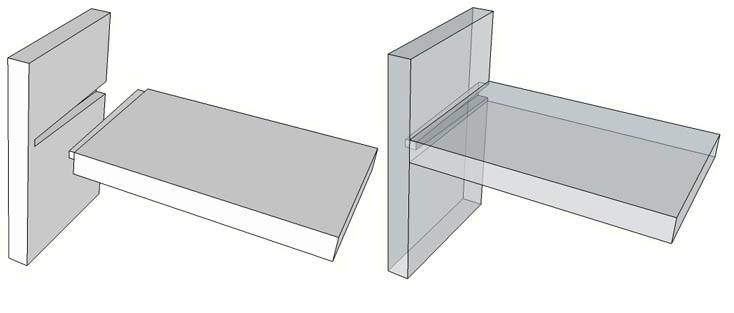

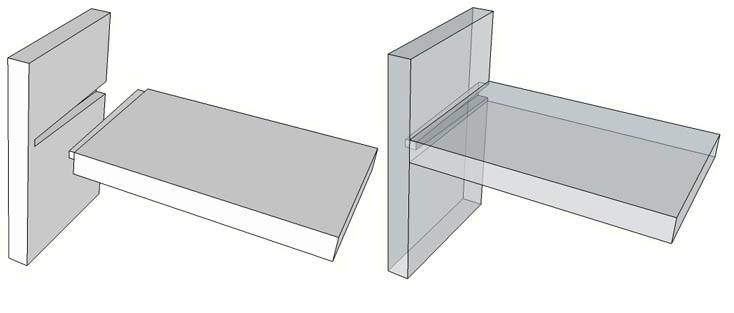

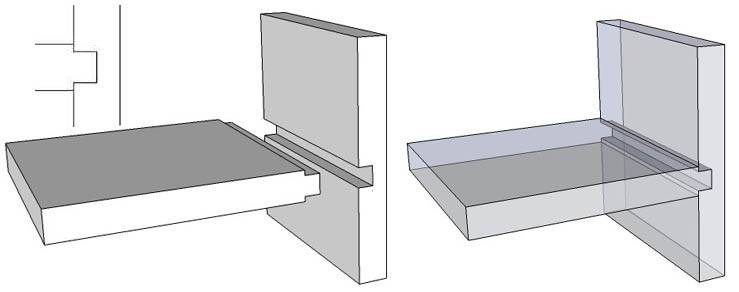

half blind dado --- A dado joint where the groove does not go all the way from one edge of the face to the other edge but rather is stopped before reaching one edge. Also called a "stopped" dado. The cut can go along the grain or across the grain, but if it goes along the grain, there is a more specific name, plough. Compare/contrast to blind dado and through dado. Examples:

half blind dovetail --- A dovetail joint where either the pins or the tails do not go all the way through one side of the mating pieces. Usually the construction is such that the pins go through and the tails do not, but this is not always the case. This half blind construction gives the strength of a dovetail but allows one face to stay clear so that a drawer front, for example, can show an unblemished face.

The terminology here is widely misused in that this joint, that is, the half blind dovetail described in this entry and pictured below, is frequently called a "blind dovetail", which is not technically correct. There IS a true blind dovetail, as I present in this glossary, but it is so onerous to construct and so infrequently used, that the terminology has slipped and the term blind is often used for what is really the half blind dovetail. Compare/contrast to blind dovetail and through dovetail joint. Examples:

half blind dovetail bridle joint --- see dovetail bridle joint

half blind dovetailed full lap --- See dovetailed fulllap

half blind dovetailed half lap --- See dovetailed half lap

half blind edge full lap --- see edge full lap

half blind edge half lap --- see edge half lap

half blind edge rabbet --- see edge rabbet joint

half blind end rabbet --- see end rabbet joint

half blind full lap --- see full lap joint

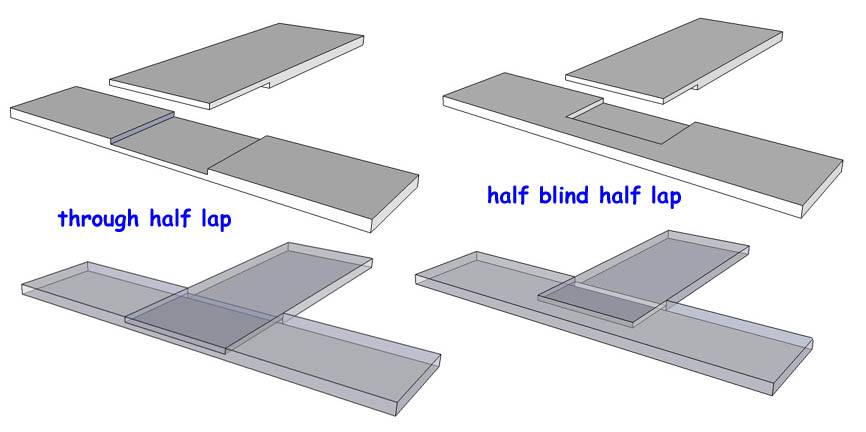

half blind half lap --- see half lap joint

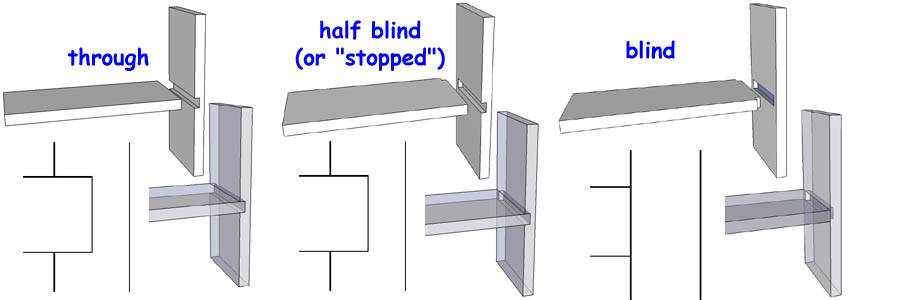

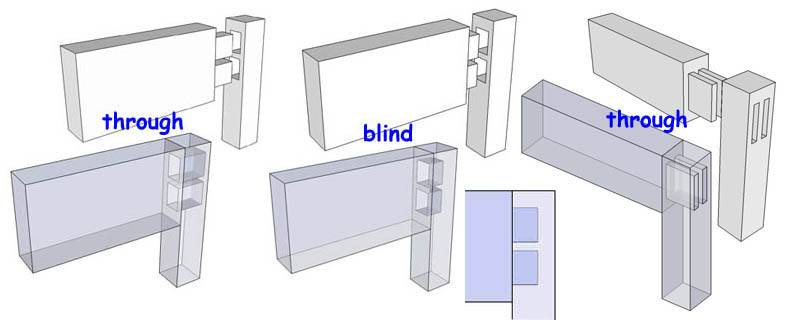

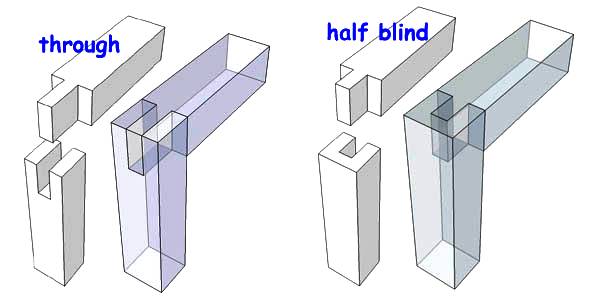

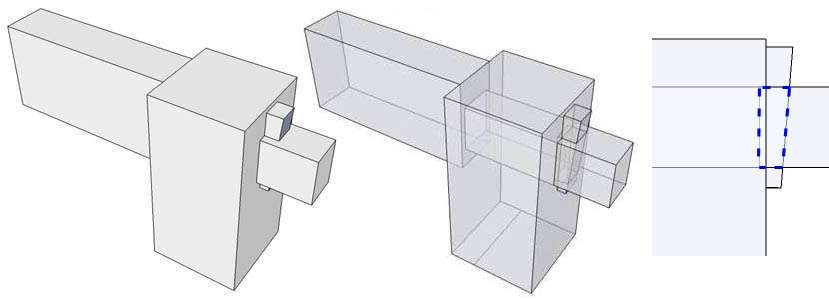

half blind joint --- Describes a joint, such as a dado joint, which could go from one edge of a board to the other but instead is stopped before reaching one edge. This is half way between a blind joint which doesn't go all the way to either edge and through joint which goes all the way to both edges. It is also called a stopped joint. Examples of all three in a dado joint to illustrate the difference:

half blind keyed dovetail full lap --- see keyed dovetail full lap

half blind keyed dovetail half lap --- see keyed dovetail half lap

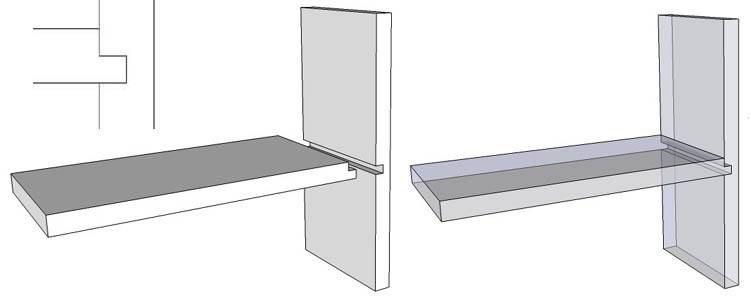

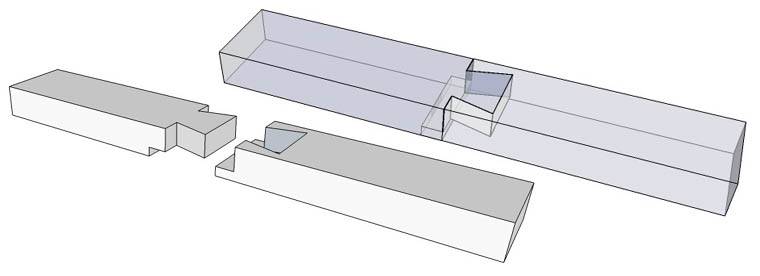

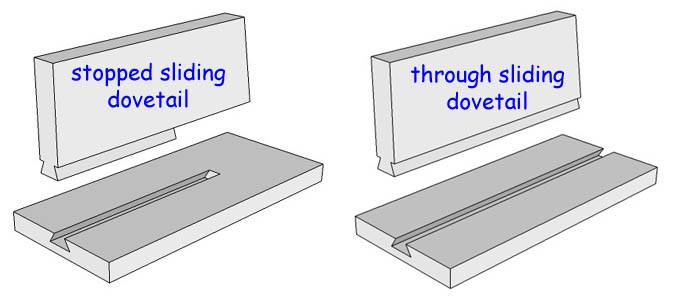

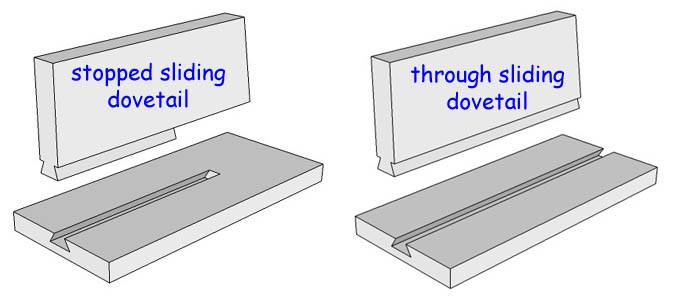

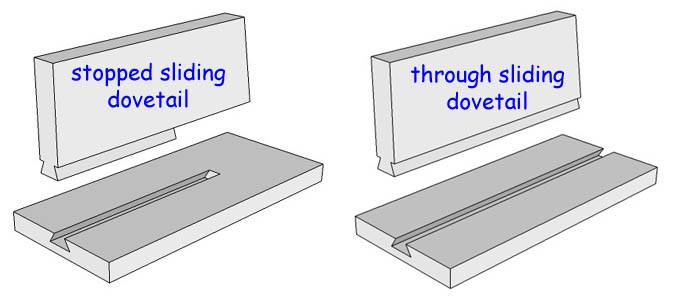

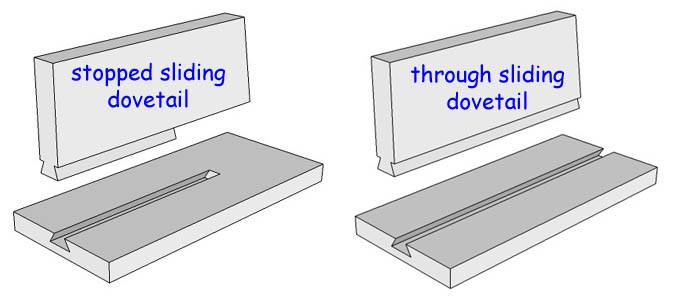

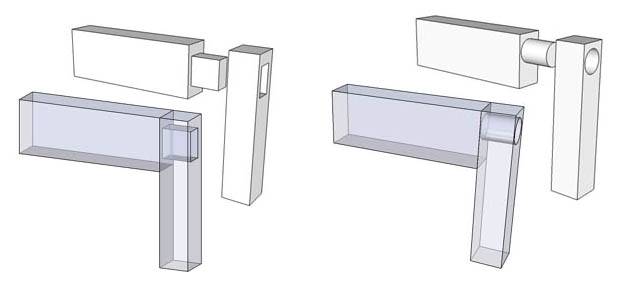

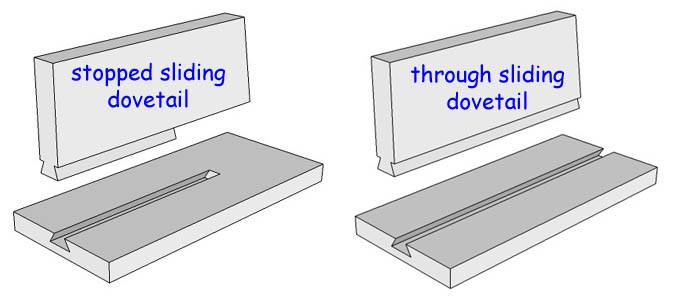

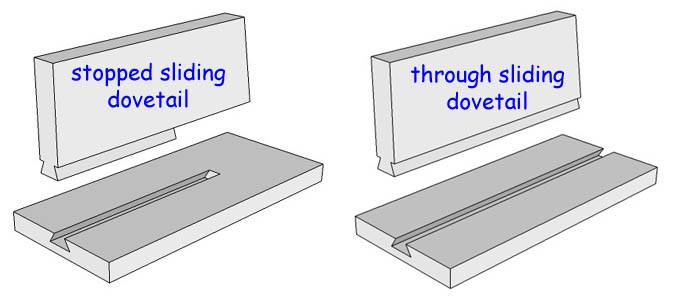

half blind sliding dovetail --- A sliding dovetail joint in which the slot is not cut all the way across the plank that it is in, but rather stops just before the edge on one side, thus making for a hidden joint when seen from the front (but obviously a dovetail when seen from the rear). Also called a "stopped" sliding dovetail and a "shouldered" sliding dovetail. Compare/contrast to through sliding dovetail. Examples:

half blind twin bridle joint --- see twin bridle joint

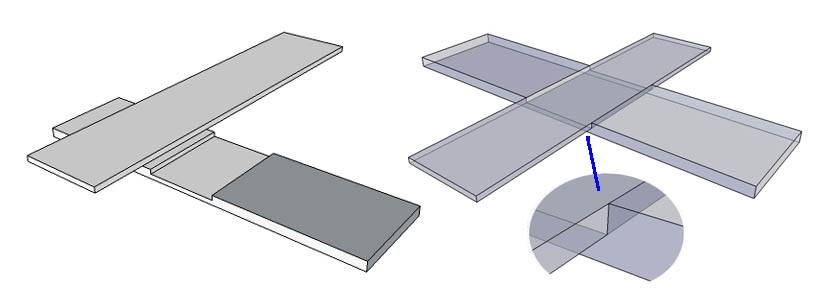

half lap joint --- A joint style in which two planks of equal thickness cross each other, fully or partially, and grooves are cut in both so that their face surfaces are flush when they mate. There are numerous types of half lap joints, depending on whether the planks cross totally or partially, whether they cross at right angles or some other angle, whether they cross in the middle or at the corners, and so forth. Many types of half lap joints are discussed and illustrated in this glossary under the terms listed below. The basic forms are illustrated directly below the list. Compare/contrast to full lap joint.

half overlay face frame door --- see face frame door

halved joint --- A joint that is basically a box joint but with one huge finger and one huge open space on the end of each plank. Because it is visually striking, this technique is sometimes used to make boxes. As shown in the examples below, the box can be just rectangular but more often the sides are shaped into a gentle curve. Because almost all of the glue surface in this joint is end grain to face grain, it is fairly weak and so, although I don't show it in the examples below, it is very common for there to be decorative (but also functional of course) pins inserted into each of the fingers. Examples:

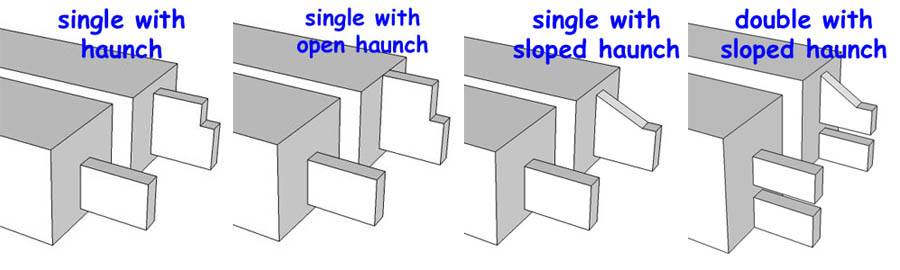

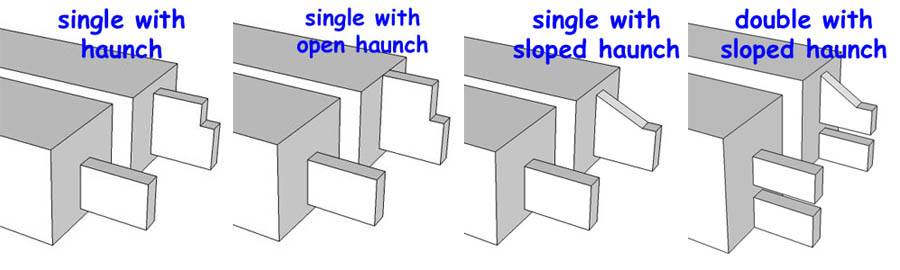

haunch --- An extra piece added to a tenon to give additional support against twisting forces. The haunch is normally added above the tenon but there's no rule saying it can't be added below the tenon if that's what makes sense structurally. See haunched mortise and tenon for an illustration.

haunched --- Has a haunch.

haunched mortise and tenon --- Sometimes, tenons that are not too big are in danger of pulling out if there is excessive twisting force applied to the piece of wood of which they are an extension. One way of alleviating this problem is to add a section that projects out above (or below) the tenon and also fits into a mating slot in the same piece that the tenon fits into; this extra piece, called a haunch, greatly increases the ability of the joint to withstand twisting forces. When such an extension is added the tenon is called a "haunched tenon" and the joint is called a haunched mortise and tenon. The haunch can be rectangular or sloped (see sloped haunch mortise and tenon) and if it goes all the way to the top of the piece the mortise is in, then it is an "open" haunch (see bridle joint). Examples of some tenons for haunched mortise and tenon joints:

haunched tenon --- see haunched mortise and tenon

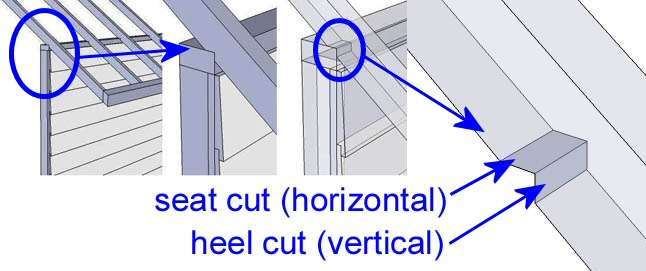

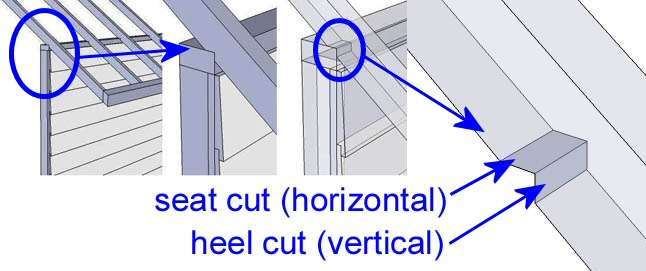

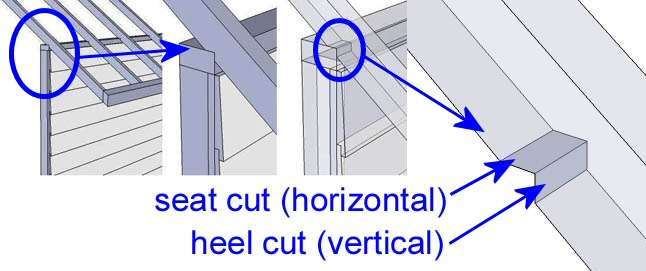

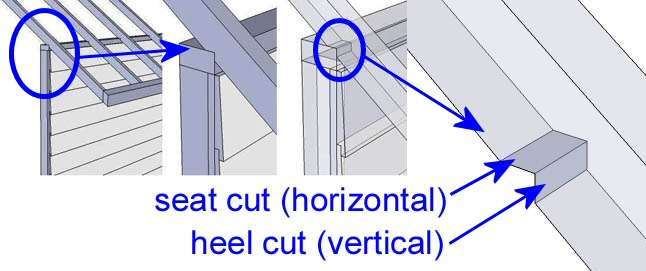

heel cut --- The vertical cut in a bird's mouth joint (rafter notch). NOTE: I have found definitions that use the term "heel cut" as being synonymous with "bird's mouth notch", but I believe that this is incorrect. I have also found definitions that say that the heel cut is synonymous with "seat cut" but I am REALLY sure that this is not correct. Compare/contrast to seat cut. Example:

horizontally wedged mortise and tenon --- This is a tusked mortise and tenon but with the wedge going sideways instead of up and down, due to the grain orientation of the piece that accepts the wedge. Wedges should always be placed such that they exert force in a longitudinal direction relative to the grain of the piece of wood accepting them, otherwise they may well cause a split in that piece. Note that the cutout for the wedge is angled at the outer edge at the same angle as the angle on the wedge, so that the wedge force is distributed evenly. Note also that the inner edge of the cutout is recessed from the face that the wedge pressure is on because otherwise the wedge would not exert any pulling force on the piece that is receiving it. Examples:

horned dado --- On a stacked head dado cutter for a circular saw, the outside blades on some sets cut just a little deeper than the inside blades (the chippers) and this results in what can, with a great deal of imagination, be looked at as a flat-topped head with little bitty horns sticking up at the sides, thus it is called a horned dado cut. Here is a greatly exaggerated example, to show it clearly:

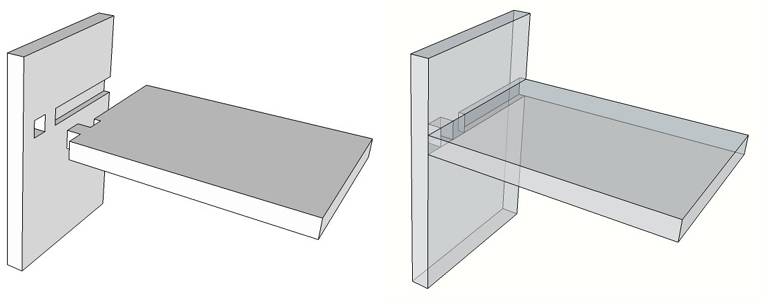

housed mortise and tenon --- A mortise and tenon joint in which the piece that has the mortise also has a slight recess into which the piece with the tenon fits. This provides considerable extra support in two directions, and is normally done to provide extra strength in the downward direction (hey, we all have to fight gravity). Examples:

inset door --- see face frame door

inset face frame door --- see face frame door

interlocking miter joint --- A complex joint that does not appear to me to be worth the rather extraordinary effort that it would take to create. Best illustrated by example, so here you go:

interlocking mortise and tenon --- see interlocking tenon

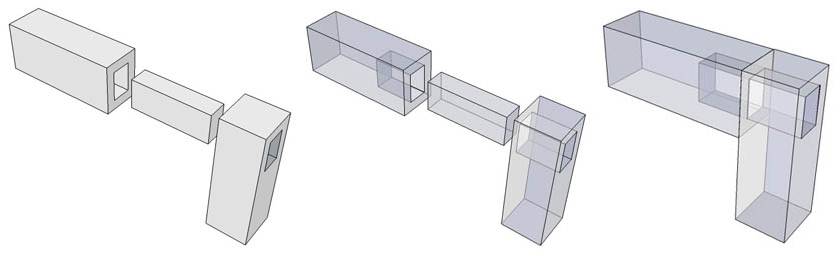

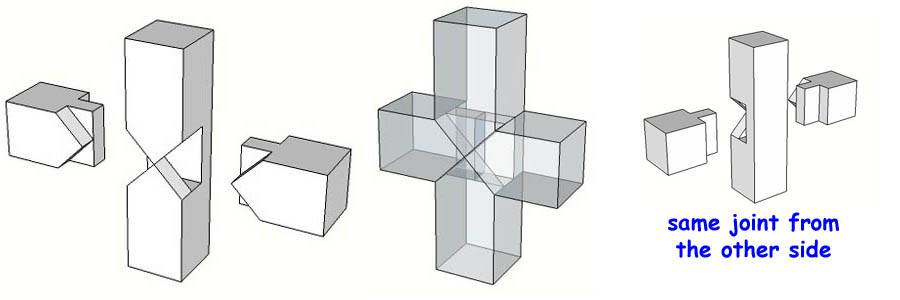

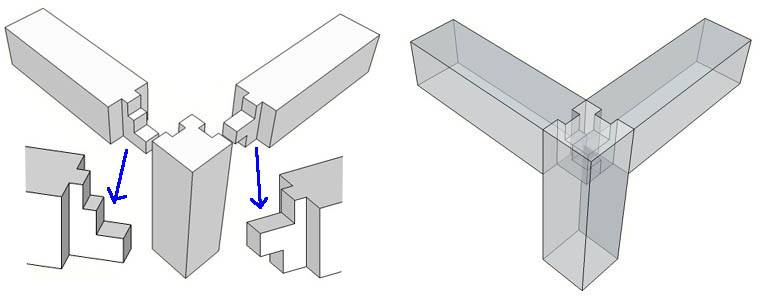

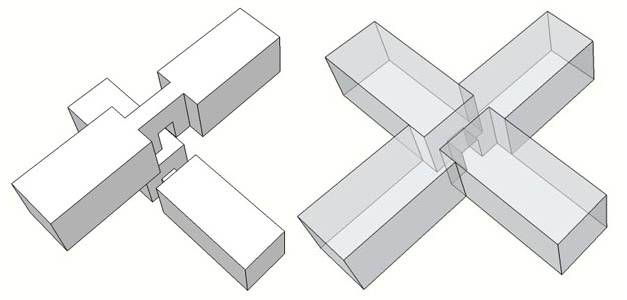

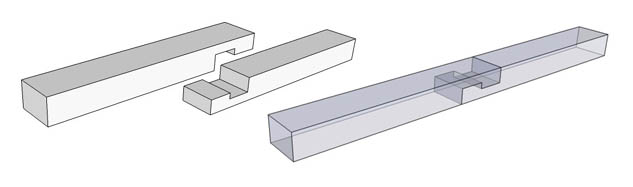

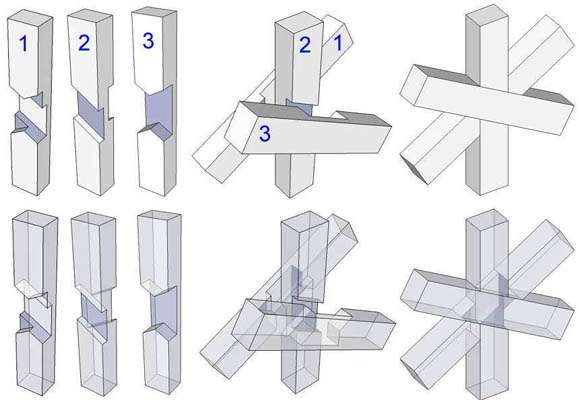

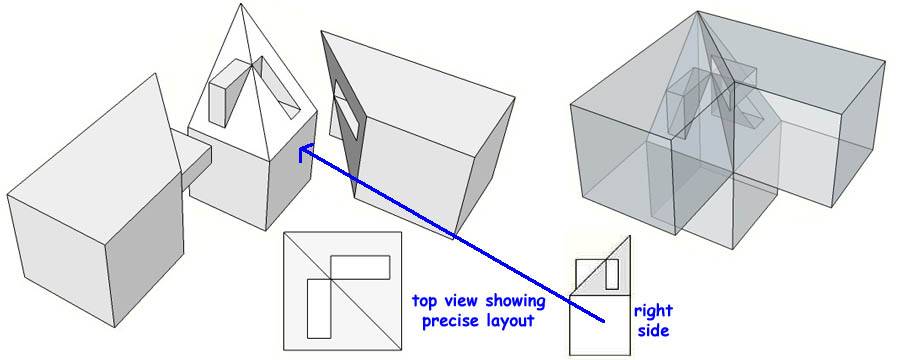

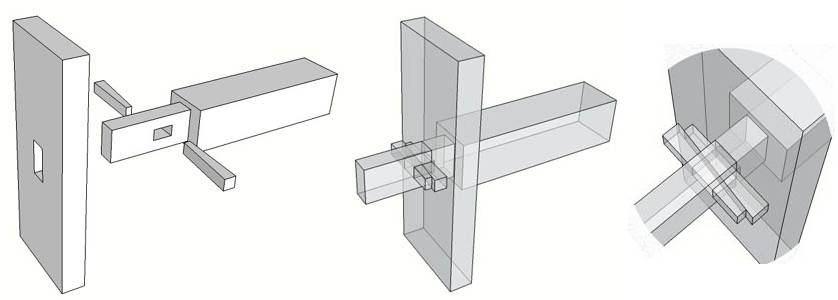

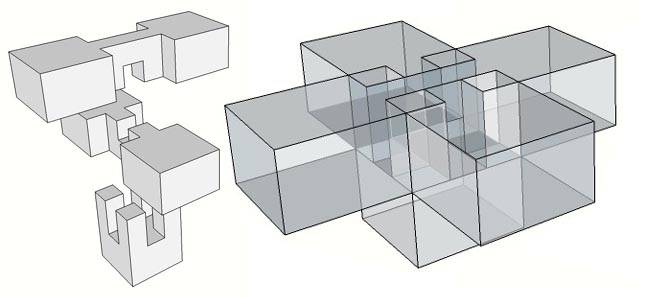

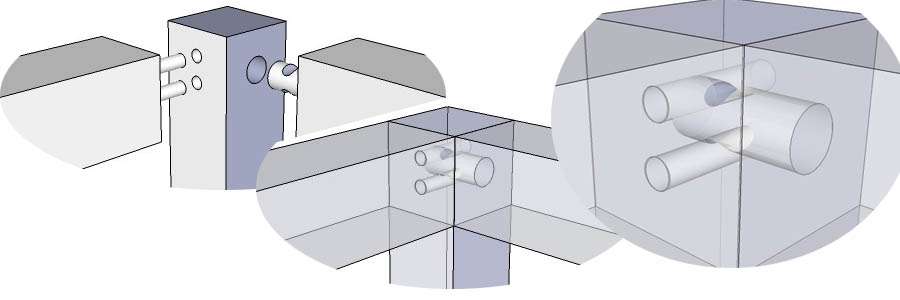

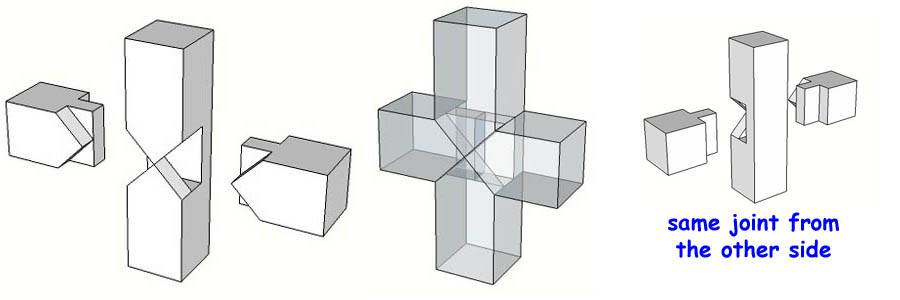

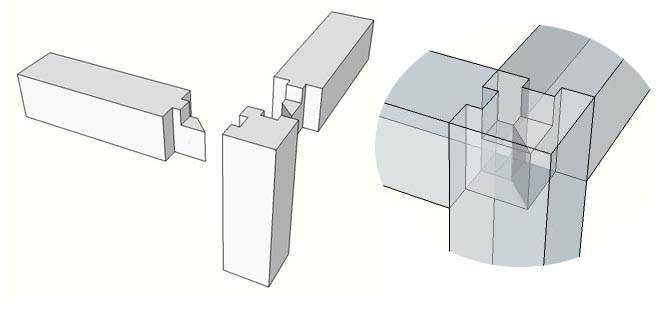

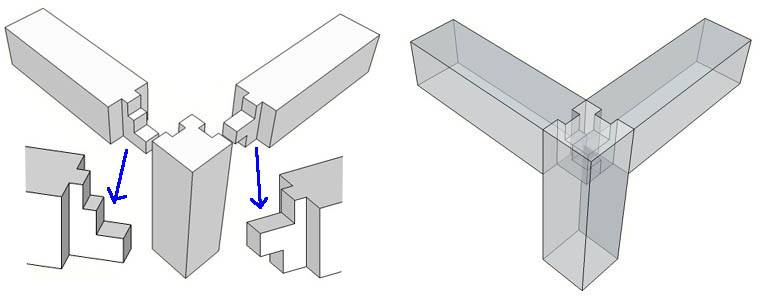

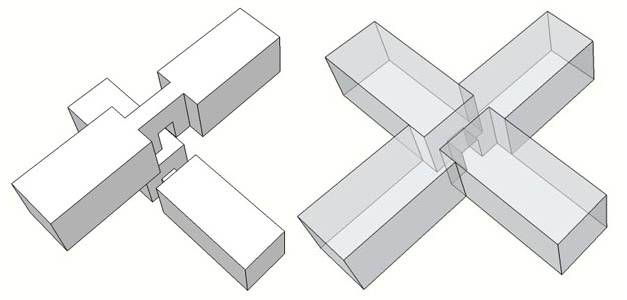

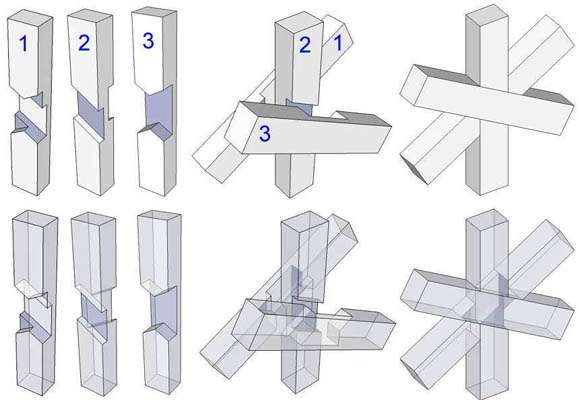

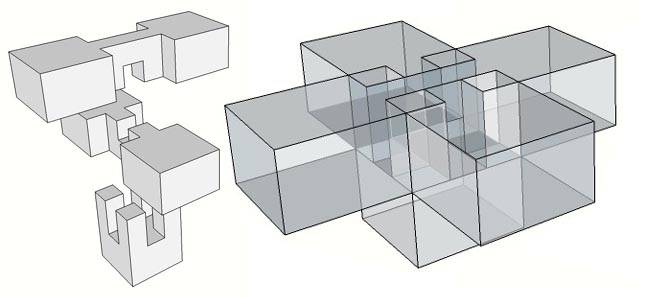

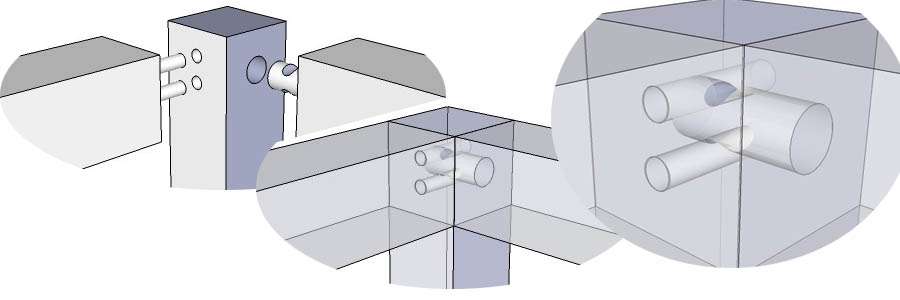

interlocking tenon --- This name is used for two fundamentally different joints. The first is a 3-way joint where the interlocking is necessary to allow all three parts to fit together and the second is a technique used in a standard mortise and tenon joint in which one of the tenons interlocks with the other one to provide extra strength against pullout. There are numerous types of the second kind of interlocking techniques. Here's the first type of joint and two of the more common ones of the second type:

Japanese joints --- This refers to joints that are very intricate and require great skill and patience. Although, as I understand it, these joints are a normal part of joinery in Japan, they are not much used in the USA. An example of such a joint is the triple miter joint.

joiner --- A woodworker who specializes in the construction of building components such as windows, doors and stairs, where the creation of good-fitting joints is very important. The objects created by a joiner are called finish carpentry.

joinery --- At the fundamental level, joinery just means creating joints between pieces of wood, but the term carries with it a connotation of fine woodworking and the creation of subtle joints that make good use of craftsmanship and woodworking skill, not just saws and nails. Nailing a couple of two-by-fours together is not joinery, creating elegant and virtually seamless dovetail joints is. In a secondary sense, it means the creation of joints in wood without the use of nails (or other metal fasteners), joints which hold together by a combination of adhesive and interlocking pieces in the edges of the pieces of wood. In a broader sense, the term is used as synonymous with cabinetry, which goes beyond just making joints. There are fundamentally two types of joinery, frame joinery and carcass joinery.

joinery chisel --- A chisel that is used to create and/or clean out a groove of some sort that is part of a joint. These, particularly the mortise chisel, tend to be stronger and stiffer than carving chisels. They often are cranked chisels. Examples

need to add joinery chisel pics

need to add joinery chisel pics

joint --- (1) The edge where two touching members or components come together

joint --- (2) The space between two touching members. One of the goals of joinery is to have clean, tight joints that are invisible, or as nearly so as possible.

joint --- (3) A type of cigarette. After smoking such a cigarette, one should avoid power tools and adhesives.

types of joints and joint-related terms:

jointed --- (1) As regards woodworking, this means joined together using any of the many joints used in joinery.

jointed --- (2) As regards tools, this means having hinged joints (like your elbow) that give certain tools or tool parts the flexibility they need to move with versatility.

jointer --- A power machine used to true the edges of boards, usually in preparation for gluing. They have rotating blades (usually a set of three blades), mounted horizontally in a holding mechanism and an adjustable infeed table that allows adjustment for the depth of the cut so that multiple passes can be made on boards that need to have a lot of material removed but not all at once. If the blades are set a little too high, then when the end of the plank leaves the infeed table, snipe occurs. Most models come with an adjustable fence, which allow one to edge boards at an angle other than 90 degrees which can be invaluable if you are making, for example, a box that is 5-sided or 6-sided instead of 4-sided. Such models are called "parallelogram" jointers because when the fence is leaned over from 90 degrees, the place where the bed and fence meet looks like one side of a parallelogram. Jointers can also be used as surface planers for narrow planks. Examples:

jointing --- The process of putting pieces of wood together by means of joints

key --- A support element used in joinery. The most common type of key is a flat arrow-head-shaped piece of wood as shown with the keyed edge miter joint and the keyed face miter joint but there is also the dovetail-shaped key element as shown with the the butterfly joint and the butterfly keyed mitered frame joint. The term is also used with joints where the "key" is not a separate element, but rather a way of making a joint more resistant to separation; this is best exemplified by the keyed lap joints such as the keyed dovetail full lap and keyed dovetail half lap

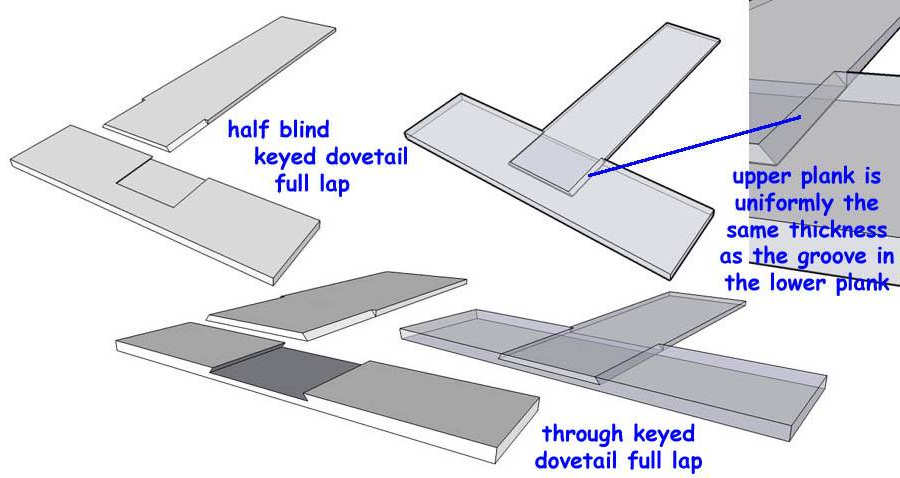

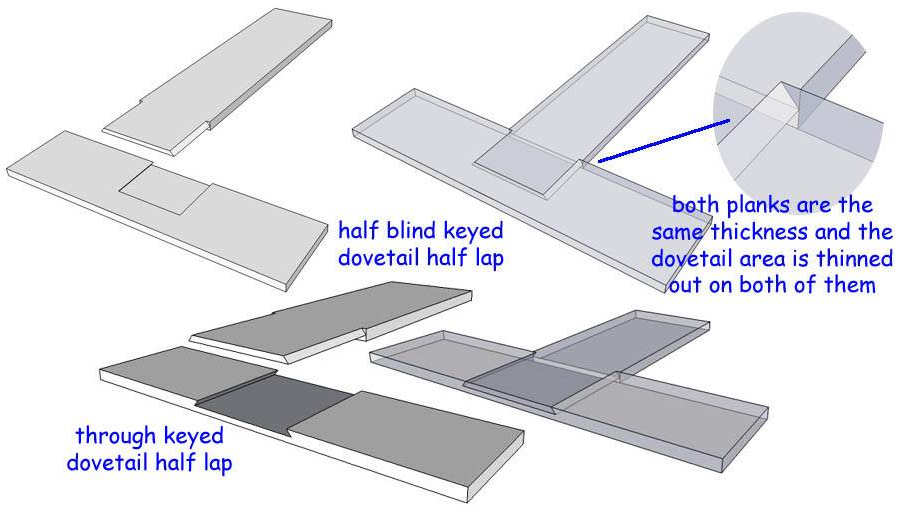

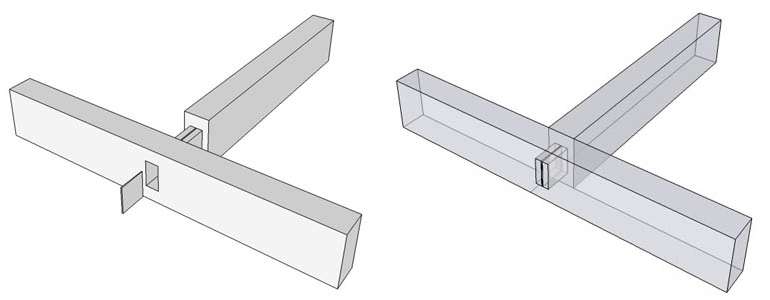

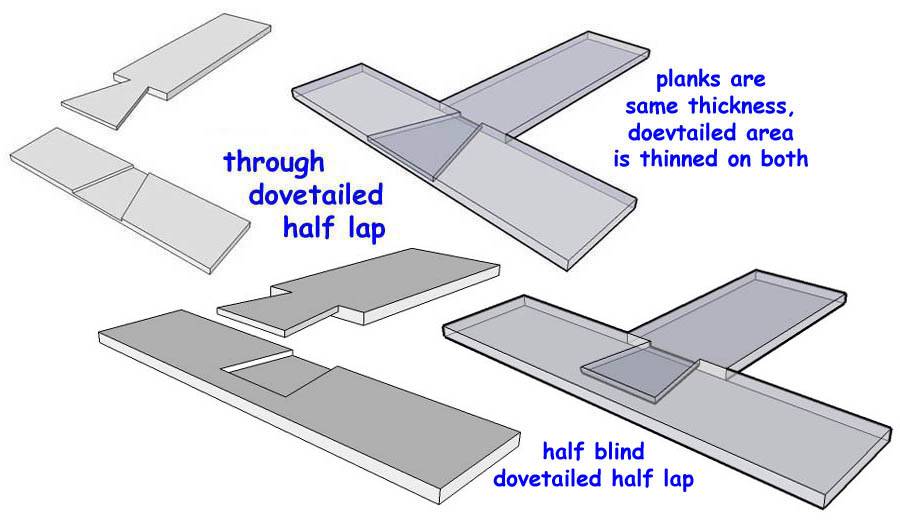

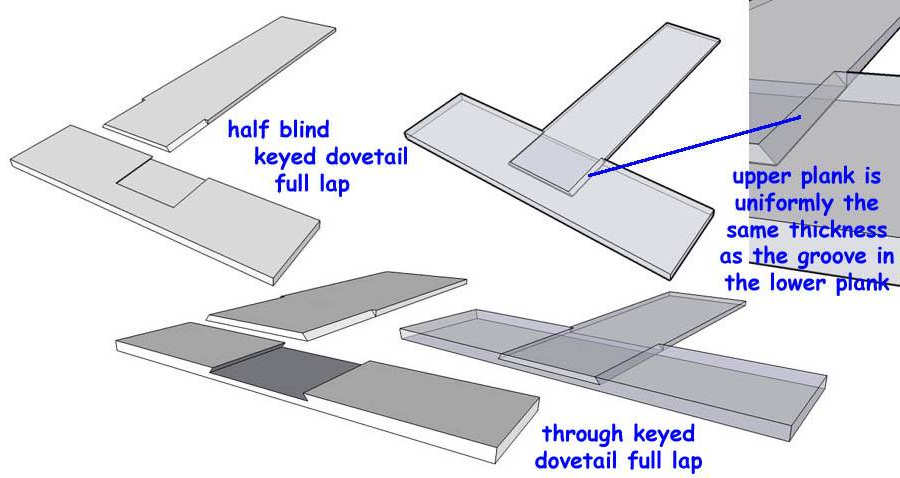

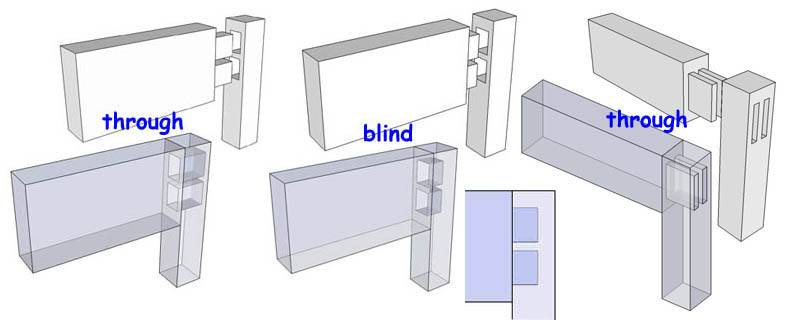

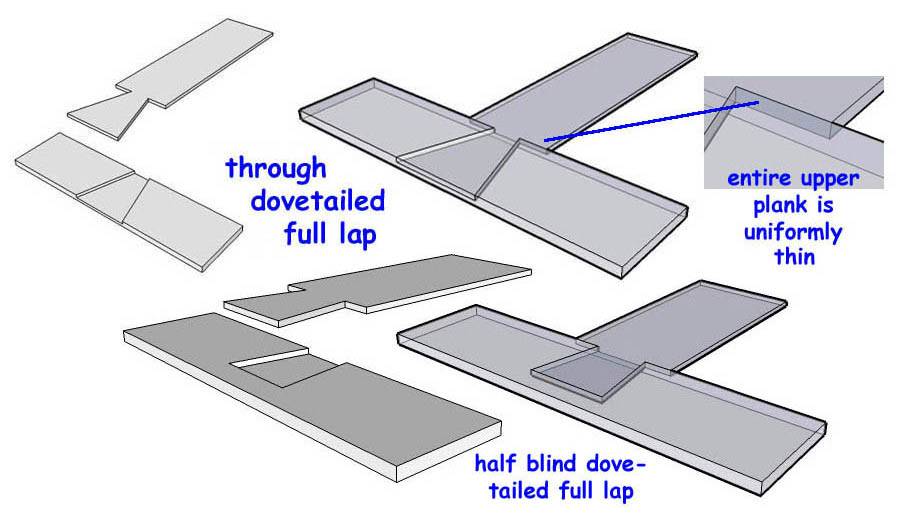

keyed dovetail full lap --- A full lap joint where the cross piece is cut with a dovetail groove instead of a rectangular groove, and the inserting piece is a large dovetail the full width of the plank. This increases the strength of the joint over just a rectangular groove. As shown in the examples below, the joint can be through or half blind. Compare/contrast to dovetailed full lap. Examples:

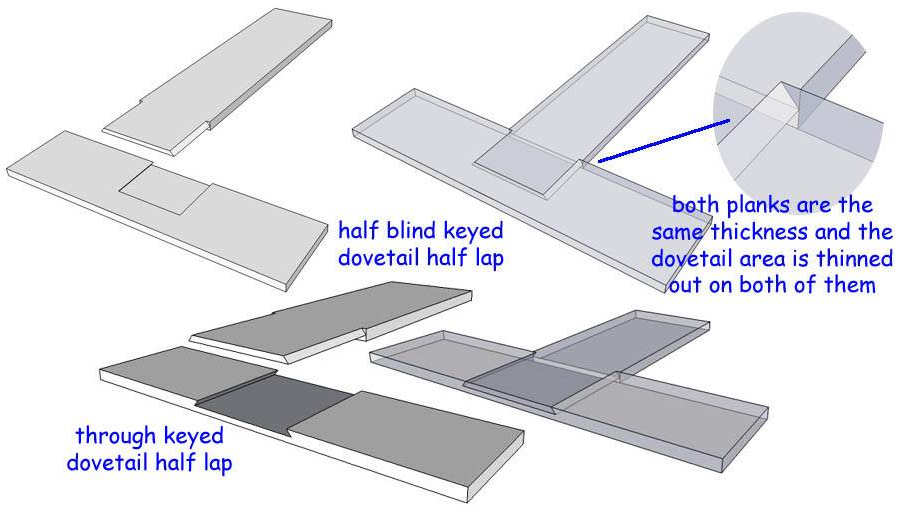

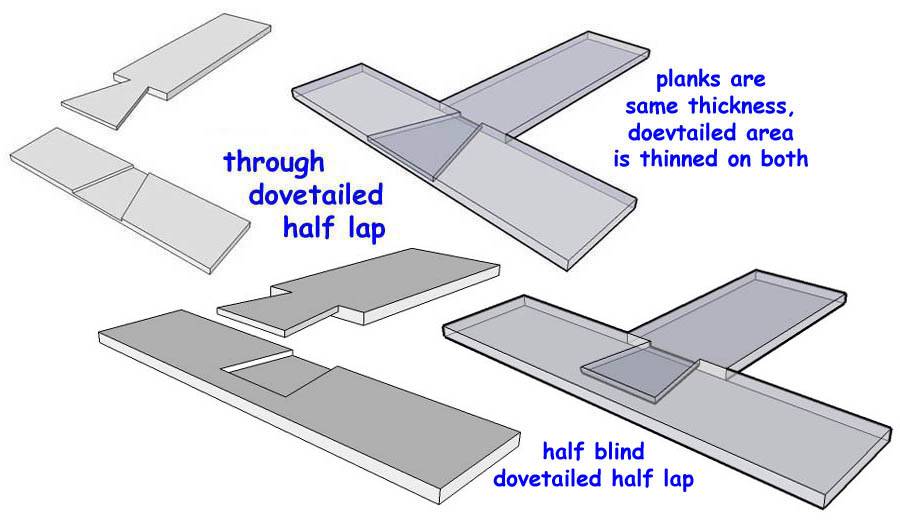

keyed dovetail half lap --- A half lap joint where the cross piece is cut with a dovetail groove instead of a rectangular groove, and the inserting piece is a large dovetail the full width of the plank. This increases the strength of the joint over just a rectangular groove. As shown in the examples below, the joint can be through or half blind. Compare/contrast to dovetailed half lap. Examples:

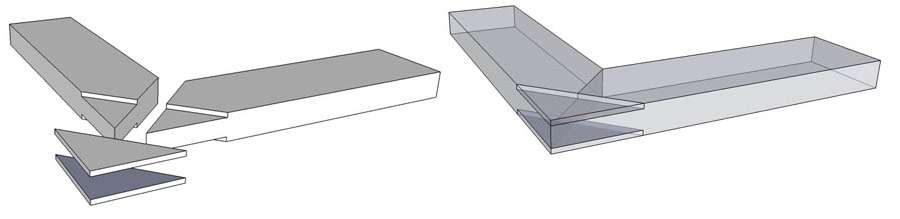

keyed edge miter joint --- An edge miter joint which is strengthened with a key. Unlike in the drawing below, one does not normally actually make the "arrow" insert so precise but oversize and then it is worked to fit after gluing. Also note that the arrow shaped key in this joint is also called a feather spline. Example:

keyed face miter joint --- A face miter joint which is strengthened with a key. Not to be confused with the very similar joint, the face keyed miter joint which has keys on the faces instead of inside. Unlike in the drawing below, one does not normally actually make the "arrow" insert so precise but oversize and then it is worked to fit after gluing. Also note that the arrow shaped key in this joint is also called a feather spline. Example:

keyed miter joint --- This refers to any edge miter joint or face miter joint in which one or more small arrow shaped splines (feather splines) are inserted into both planks to a depth that is less than what would make them protrude through to the inner side. The two examples in this glossary are at keyed face miter joint and keyed edge miter joint

knockdown --- (1)[adj] A design feature that allows a piece of furniture to be easily disassembled by the use of special hardware or joinery (sometimes called knockdown fittings and/or knockdown joints.

knockdown --- (2)[noun/verb] The process of disassembling furniture that is built as described in the adjective definition above.

knockdown --- (3)[noun] see knockdown joint

knockdown fittings --- Mechanical devices (hinges, etc.) for joining components in furniture that has to be easily dismantled. See also knockdown joint.

knockdown joint --- Any joint that is constructed without glue and in a way that it can be disassembled easily. Such joints often use removable wedges but may also use various metal fasteners that allow for disassembly.

lap --- (1)[noun] See lap joint

lap --- (2)[noun] The area where sections of roll roofing or rolled underlayments overlap one another when the material is being put into place.

lap --- (3)[verb] To position adjacent objects so that one surface extends over the other. Term may designate a lap-siding technique for roof shingles or siding shingles or other house siding, in which each panel or piece overlaps the edge of the next lower one. Also, the creation of a lap joint

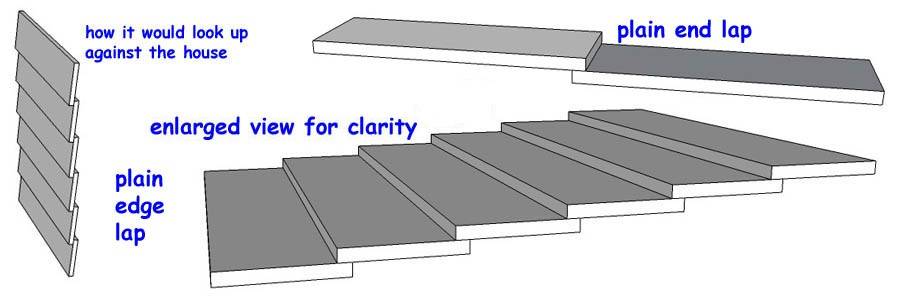

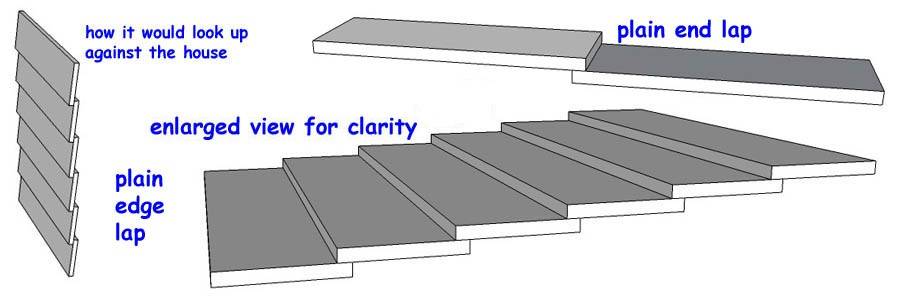

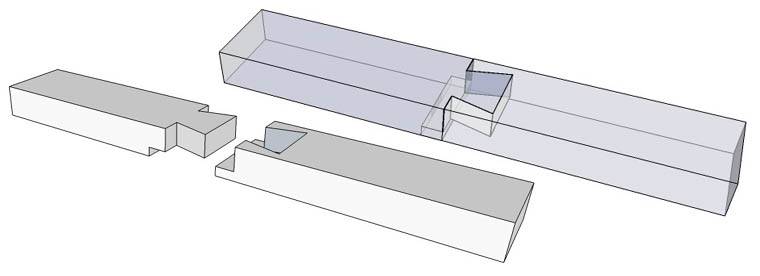

lap joint --- A joint made by cutting of part of the face off of one or both of two planks and then placing one over the other so that the faces are flush with each other and then bonding the overlapped portions. This can be at the ends or in the middle, and there are specific names for the particular forms. Also called "shiplap" joint. When one of the mating pieces is only as thick as the groove in the other piece, the joint is a "full lap" joint and when the two planks are the same thickness and half is cut out of each one, it is a "half lap" joint (there are a couple of exceptions to these general rules). There are a huge number of variations on this joint, most of which are fully explicated in this glossary under the following set of terms for full lap and half lap joints:

lapped dovetail scarf --- A lap scarf joint in which the lapped portions are shaped as a dovetail joint. There is another version that I think is a better joint, albeit somewhat more complex to create, and that is the shouldered lapped dovetail scarf. Examples:

lapped dovetail splice --- I have seen this name used for both the lapped dovetail scarf and the shouldered lapped dovetail scarf.

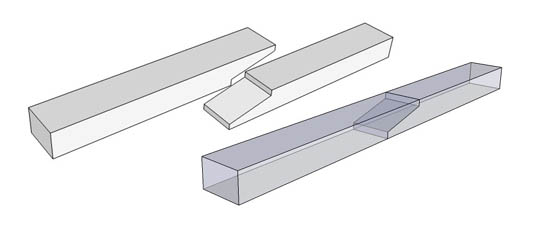

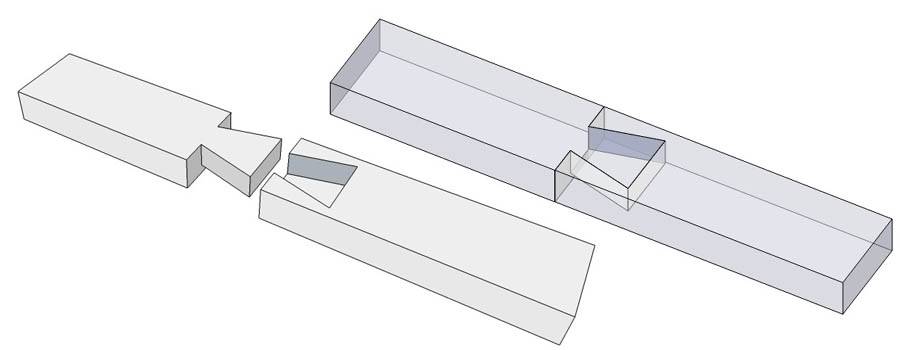

lap scarf --- A scarf joint with a simple lap in the ends of the mating planks rather than the angled cut of the "standard" scarf joint. Examples:

locking rabbet --- This is the simplest form of a joint that exists in more complex forms called (1) the drawer locking joint and (2) the double dado. Like those joints, it is used for drawer front/side joinery. Example:

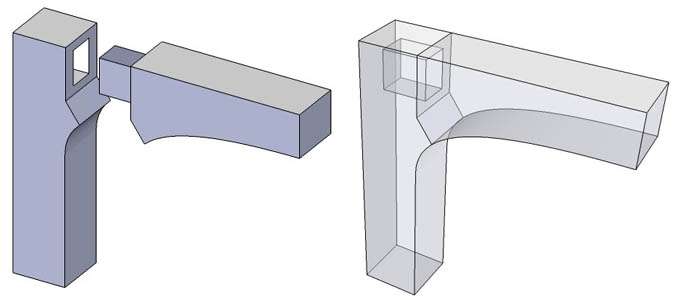

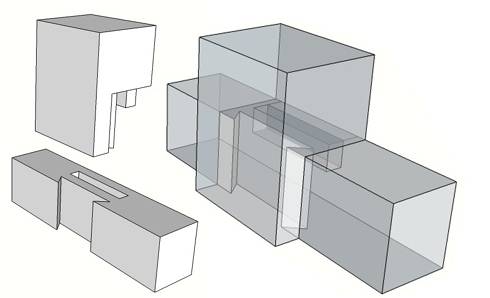

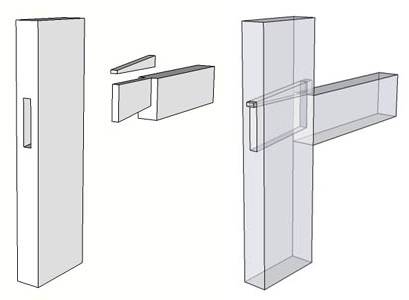

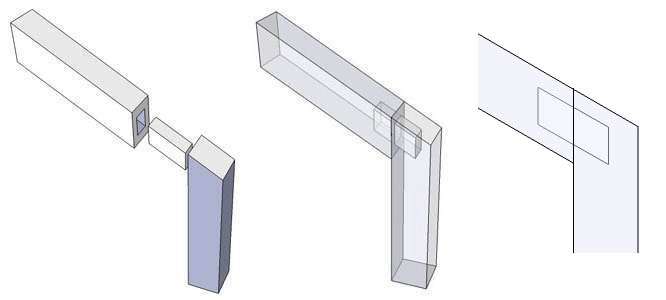

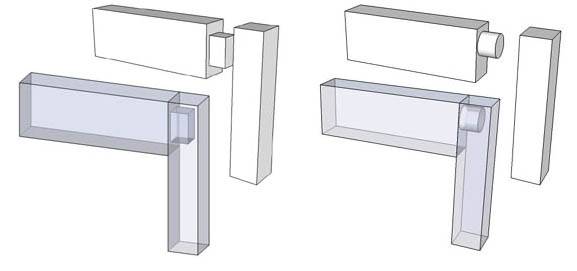

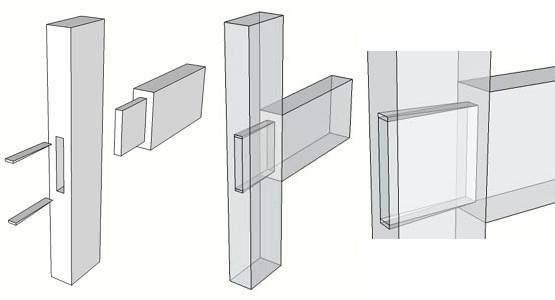

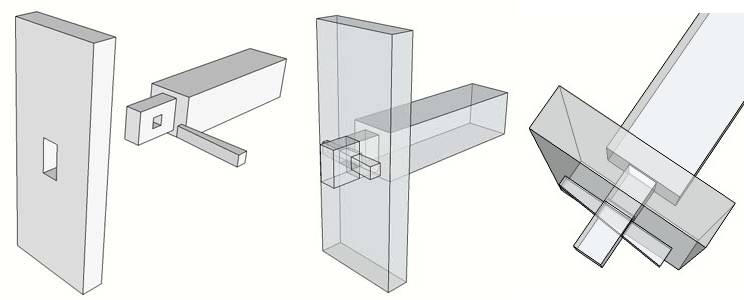

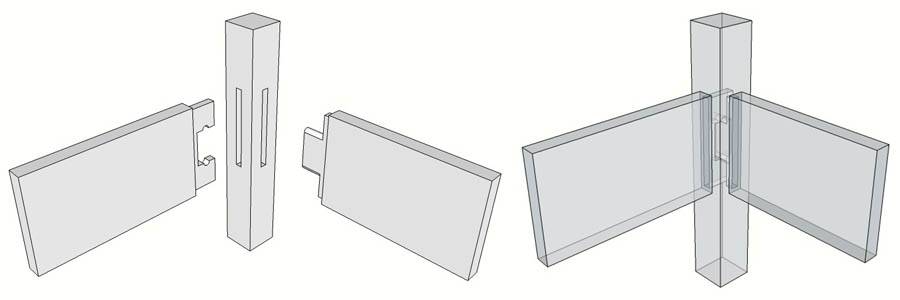

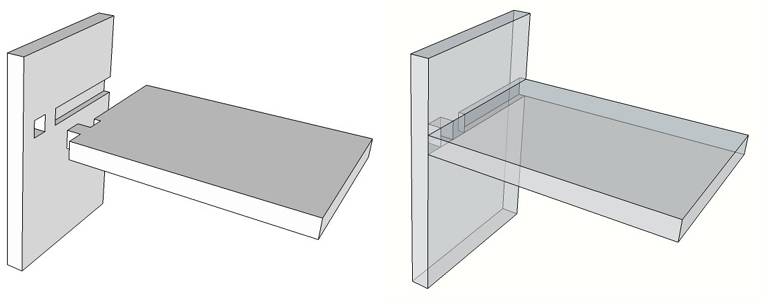

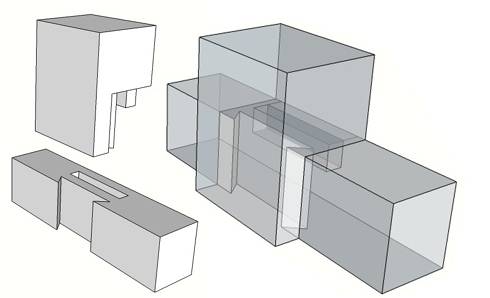

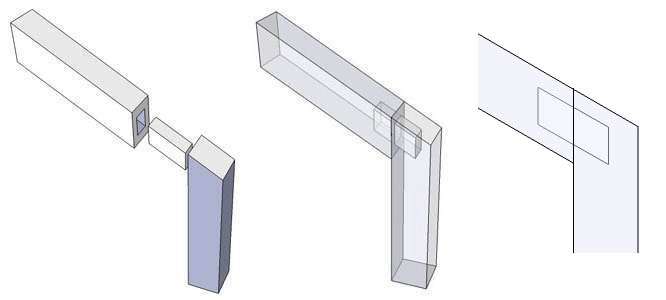

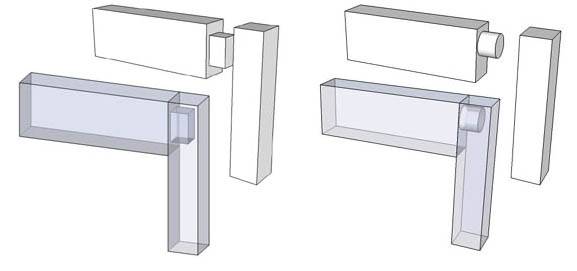

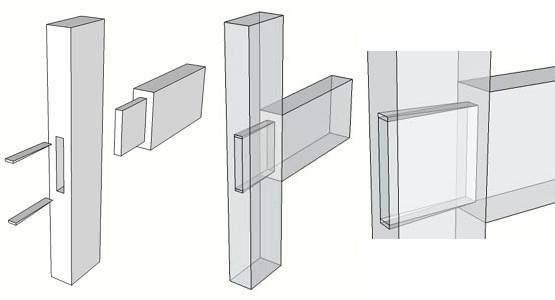

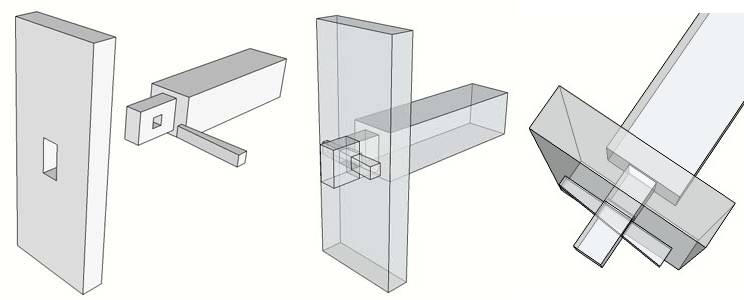

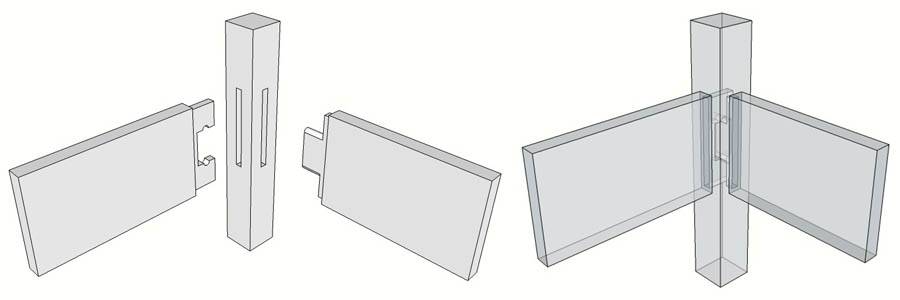

loose mortise and tenon --- This is a variant on the standard mortise and tenon joint, the difference being that the tenon is not part of one of the joining pieces but rather is loose, like a spline, so that the joint actually has two mortises and a loose (also called "floating") tenon. Example:

loose mortise and tenon with angled shoulder --- see angled shoulder mortise and tenon

loose tenon --- see loose mortise and tenon

miter --- (1)[verb] To make a diagonal cut at specific angle (often 45 degrees, but it could be 30 degrees or any other angle), with the purpose of fitting two workpieces (e.g. two sides of a picture frame) together.

miter --- (2)[noun] A cut made as described in (1) above. See miter cut for an illustration.

miter --- (3)[noun] synonymous with miter joint

related terms:

miter and spline joint --- see splined miter joint

miter box --- An apparatus to guide a saw (usually a backsaw) to make miter joints. The cut produced can be at an angle to the long dimension of a board, or to the face. Examples:

miter box saw --- synonymous with back saw

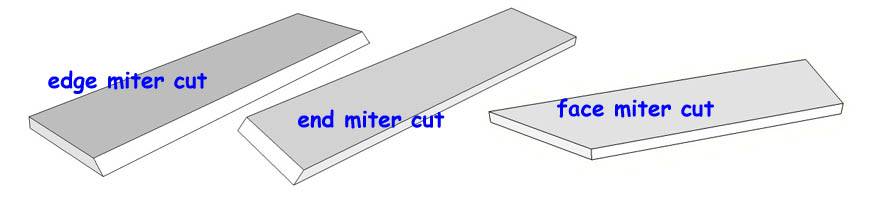

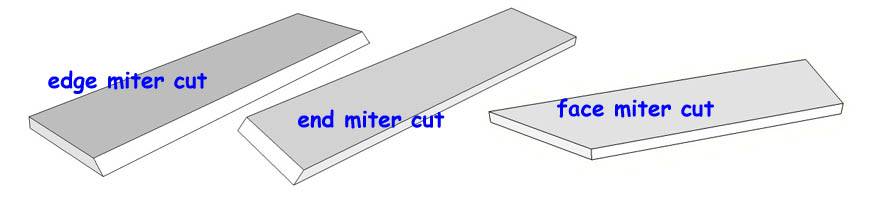

miter cut --- A diagonal cut at specific angle (often 45 degrees, but it could be 30 degrees or any other angle), across the end of, or along the edge of, or across the face of, a plank. When the cut is at an angle to both the edge and the face, it is a compound miter cut. Examples:

mitered --- Cut at an angle. See also, miter joint.

mitered blind dovetail --- A dovetail joint that has the pins and tails hidden inside a miter joint. This is a really nifty looking joint, but I have to believe that the only people who actually make it have WAY too much spare time on their hands. Example:

mitered bridle joint --- A joint like a standard through bridlejoint except that the prong and groove are mitered rather than being square. Examples:

mitered corner dovetail joint --- A joint used for joining the ends of two roughly square cross sections pieces by putting a single dovetail in one and the corresponding mortise in the other. Best described by illustration, so here you go:

mitered edge rabbet --- see mitered rabbet

mitered end rabbet --- see mitered rabbet

mitered full lap --- A type of corner full lap joint where the two mating pieces have their extending parts cut at an angle (mitered). Examples:

mitered half lap --- A type of corner half lap joint where the two mating pieces have their extending parts cut at an angle (mitered). Examples:

mitered joint --- A joint that includes a miter cut. (see miter joint.

mitered rabbet --- This is a cross between a standard miter joint and a standard rabbet joint that makes it about half of each. By using the square faces of the rabbet, the joint has more resistance to slippage of the pieces relative to each other than does a miter joint, but by using the miter joint at the outer edge, the joint maintains the somewhat more elegant characteristic of having the joint line right at the corner rather than off of the corner as is the case in a rabbet joint. If the joint is at the ends of two planks, it is called a mitered end rabbet and if it is along the edges of two planks it is called a mitered edge rabbet. Examples of both:

mitered shoulder mortise and tenon --- There are two distinct joints that are both given this name:

type 1 --- This is a joint that might be used on the back of a chair or on a fancy-shaped mirror frame. It is a common blind mortise and tenon joint (although it COULD be done as a through joint, and it could be haunched) but it is put into pieces that are not rectangular in shape, as shown in the illustrations below. The area below the tenon (the shoulder) is mitered as it moves away from the tenon.

type 2 --- This is a significant variation on a standard mortise and tenon and accommodates a pair of rails coming into a common leg, with each rail having a standard tenon but rather than have a vertical shoulder next to the tenon, the shoulder on one side is mitered, as shown in the drawing.

Examples of type 1:

Examples of type 2:

mitered sticking mortise and tenon --- see mortise and tenon with mitered sticking

mitered tenon --- This is a standard blind mortise and tenon joint but with a twist, which is that the piece with the mortise receives tenons from two directions (actually it could even be 3 or 4) and the tenons have to be mitered on the ends so that they will go into the joint as far as possible for maximum strength. The joint can be haunched or not, as you please. A variant on this joint, but one that does not require a miter, is the notched mortise and tenon joint. Examples:

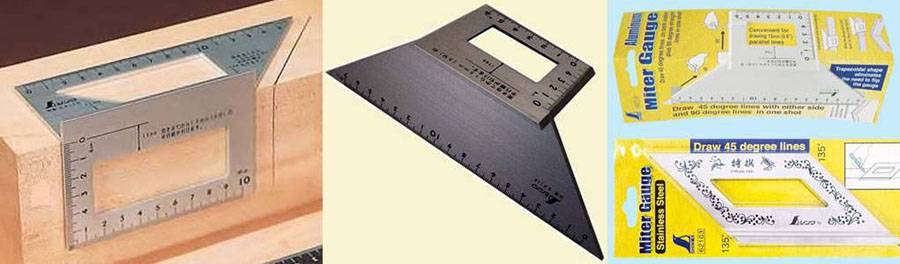

miter gauge --- (1) A tool that slides in a slot on a table saw, router table, bandsaw, etc. and which can be adjusted to different angles so as to slide the stock past the blade to achieve an angled cut.

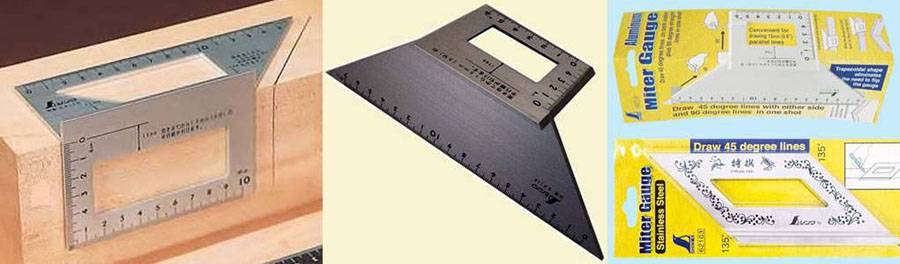

miter gauge --- (2) A piece of angled metal or hard plastic, 2D or 3D, that accurately lays out where to mark wood for one or more angles for miter cuts.

Examples of definition (1):

Examples of definition (2):

miter joint --- A joint between two pieces of wood where the edges of each are cut at an angle (usually each at 45 degrees but it doesn't have to be that). The primary purpose of miter joints is to hide end grain. There are more different types of miter joints than you can shake a stick at. Here are a few of the most common:

mortise --- (1) A shallow cutout in the surface of wood for the purpose of mounting something (such as a hinge) so that it sits flush with the surface of the wood.

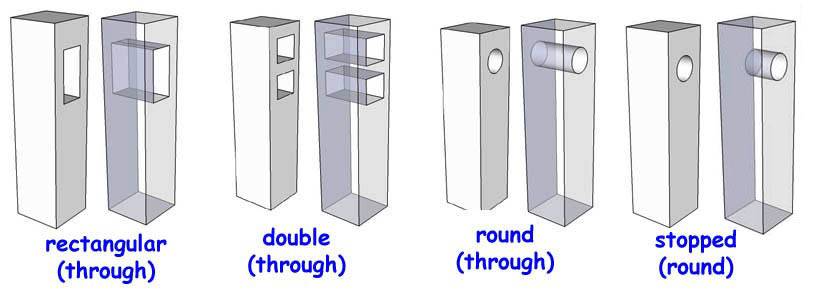

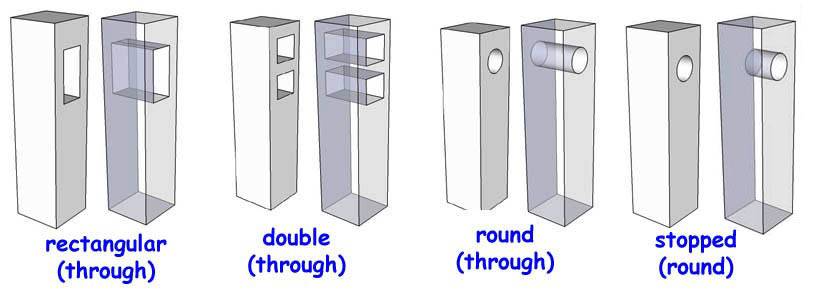

mortise --- (2) A rectangular recess into a piece of wood for the insertion of a tenon to form a mortise and tenon joint. The term is also used in a more general sense for any recess that might take some projecting piece similar to a tenon, even if it is not strictly a mortise and tenon joint. The mortise may go all the way through the piece it is in or it may stop short of the face opposite the entry point. Examples:

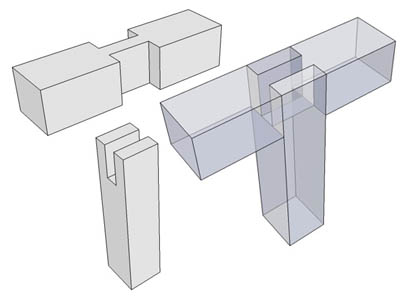

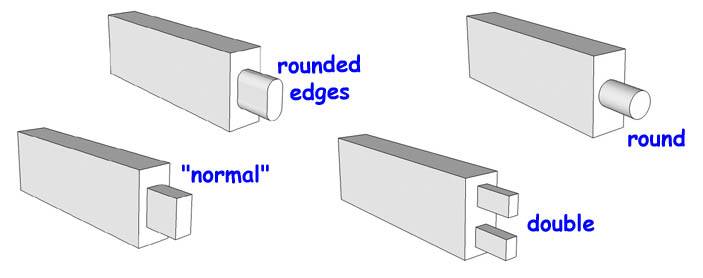

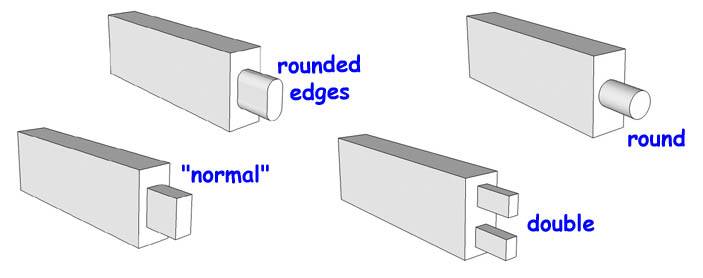

mortise and tenon --- A wood-jointing technique in which the end of one piece is reduced to create a projecting section (the tenon) and a section of the other piece is hollowed out (creating the mortise) to hold the projecting piece. The cross section of the tenon can be square, rectangular, circular, or even oval and when square or rectangular the edges may or may not be smoothed over. There are a HUGE number of variations on this basic technique. When the mortise is cut all the way through the receiving piece, it is called a through joint and if the mortise is not cut all the way through, it is called a stopped joint or stubbed joint (or blind joint) and the tenon is called a stub tenon. In cases where there might be considerable twisting force, an additional piece, called a haunch is added to the tenon. If there are two tenons (and two mortises) then it is called a "twin" mortise and tenon. For illustrations, see the various types shown in this glossary:

mortise and tenon with mitered sticking --- Some rail and stile planks come with sticking already molded onto the edge as part of the plank. This complicates the offset shoulder mortise and tenon joint that is often used to mate them. The sticking has to be either coped or mitered. This joint is the mitered version and it is best described by a drawing, so here you go:

notched mortise and tenon --- This is a standard blind mortise and tenon joint but with a twist, which is that the piece with the mortise receives tenons from two directions and the tenons are cut so that one fits partly over the other, thus allowing them both to penetrate into the mortise as far as possible for maximum strength. Although the example shown below is drawn as an open mortise and tenon (see bridle joint, it obviously does not have to be open. A variation on this type joint is the mitered tenon. Examples:

notched scarf --- This is a very minor variation on the standard scarf joint, made by cutting off the sharp ends. Examples: