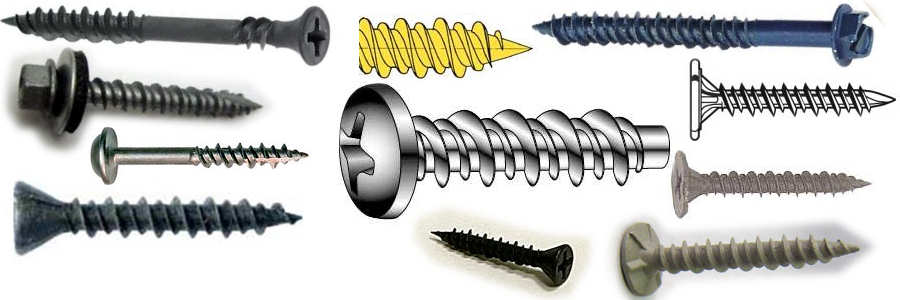

| binding head screw

|

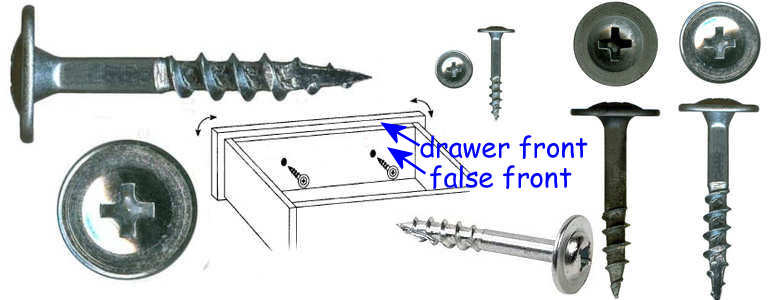

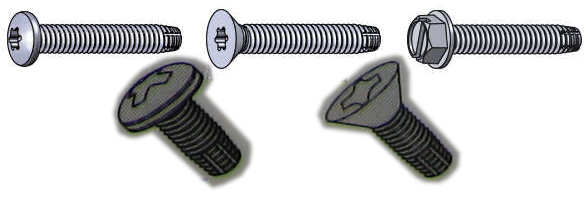

binding --- undercut under the head or with extra wide head, so as to trap (bind) electrical wires or connectors. That is, the type is defined more by function than by shape, so there are several head types several drive types

|

|

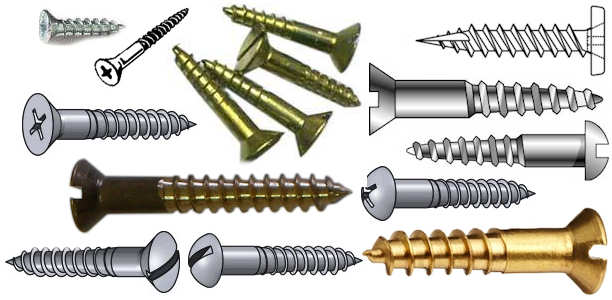

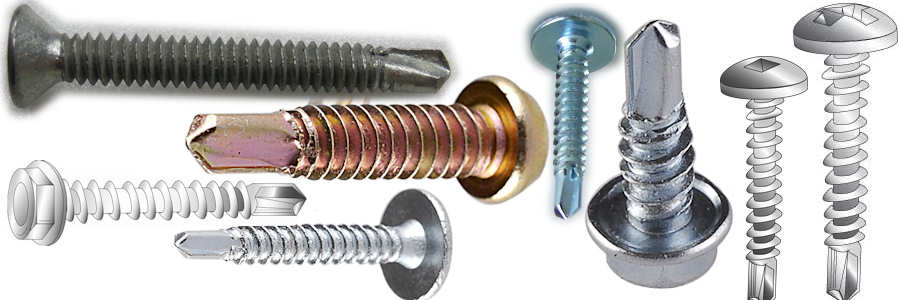

bugle --- a curved countersink, mostly used to avoid crushing drywall; usually has a phillips drive

|

|

button --- like pan but more curve on top and always has a Allen drive socket

|

|

cheese --- like a flat fillister but thinner (about half as high as wide). The definition calls for a cylindrical wall but in practice they are sometimes sloped (so the wall is a cone section, not a cylinder). Drive slot is most often flat head. Also, in practice, lower profile flat fillisters, which SHOULD be called cheese head, are in fact still called fillisters

|

|

countersunk --- angled sides to allow flush mount (non-protruding head). The bugle head is also a countersunk head, but what is shown here is the "standard" straight (but angled inward) wall. Drive can be any style. This type of head is not, as far as I am aware, ever used with large bolts, just screws and the small bolts that are often called machine screws.

|

| mirror screw

|

dome --- same as mirror (but term is also loosely used for other domed heads)

|

|

fillister --- high cylindrical-walled head with a rounded top and deep drive slot for a flat head screwdriver and with less tendency for cam-out than normal flat head slots. There are fillister heads that use an Allen drive instead of a flat head and even some that use a Phillips head drive, but mostly you will find them with flat head drive slots. Typically used in a counter-bored hole.

|

|

flange --- integral wide washer provides extra holding surface. Drive can be any type but seems to be most often Phillips slot or hex head.

|

| same as countersunk

|

flat --- same as countersunk

|

|

flat fillister --- same as fillister, but without the slight curve on top. Although technically a flat fillister with a head that isn't very high is called a cheese head, in practice this distinction is often not made. Also, as you can see in the composite image to the left, items sold as "flat fillister" have a full sized head and should be called just fillister (check out the silver one on the left).

|

| set screw

|

headless --- this is a set screw

|

|

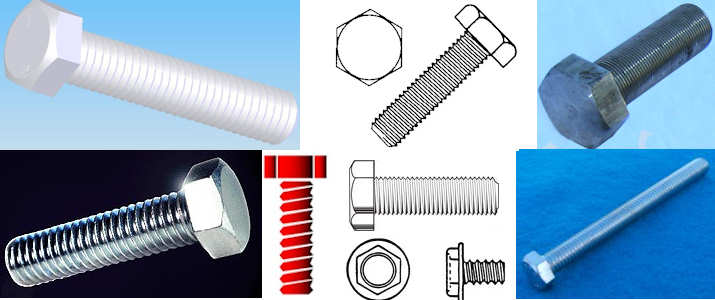

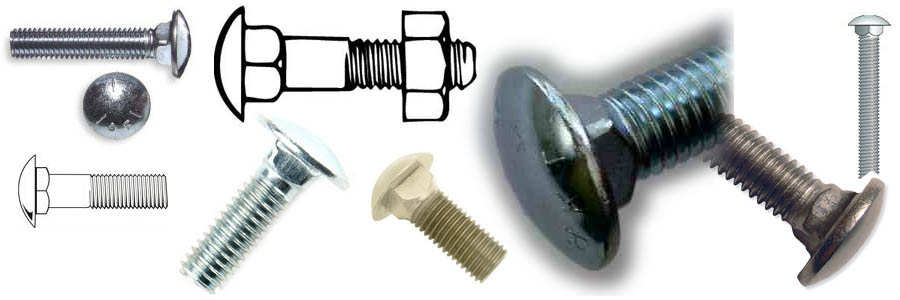

hex --- hexagonal head, very common, easy to drive with socket set, crescent wrench, pliers, etc. This is the most common head for bolts and has largely replaced the older square head.

|

|

hex washer --- like hex but has an attached washer-like flat flange. Typically, the outer portion of the hexagonal part is raised above the inner portion to provide extra gripping area for the driver. There is a specify type of these that are slotted (see below; slotted hex washer)

|

|

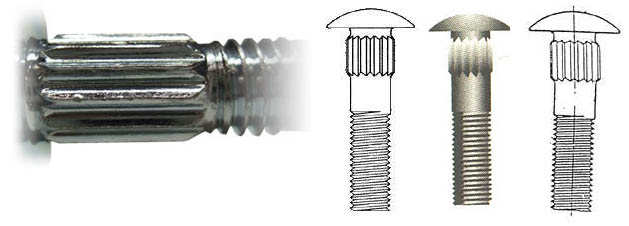

knurled --- has indentations, usually a cross-hatch, so you can turn it with your thumb and forefinger. It may or may not also have a drive slot

|

|

low head socket cap --- what it says; a socket cap head that is lower than usual. In practice, I found a great many items sold as "low head" socket caps that had the same high head as normal ones.

|

| same as spade

|

paddle --- same as spade

|

| mirror screw

|

mirror --- screws with various kinds of separate decorative tops that go over the actual screw

|

|

oval --- like a countersunk head but with shallow-domed top instead of the normal flat top of a countersunk head

|

|

pan --- domed cylinder; the exact shape will vary a fair amount depending on manufacturer; there may even be a flat area on the top or it may look more like a round head

|

| same as oval

|

raised --- same as oval

|

|

round --- hemispherical, mostly for decoration (similar to mirror, but the top is integral to the screw not a separate item); the exact shape will vary a fair amount depending on manufacturer; in practice, items sold as "round head" can look more like a pan head

|

|

round washer --- round top and with an integral washer under it; the top is usually not as domed as on the normal round head, it's more like a truss head.

|

|

serrated flange --- same as flange head but there are serrations on the bottom of the head that are raised on the side opposite the insertion direction so as to inhibit vibrational loosening of the screw or bolt (exactly as on a serrated flange nut). This head is found almost exclusively on hex-head bolts.

|

|

shouldered spade --- same as spade but with a flange ("shoulder") above the threads

|

|

slotted hex washer --- hex washer head but also slotted for a flat head screwdriver

|

|

socket cap --- a cylindrical bolt head that takes an Allen drive (ocassionally other types of drive). The rim of the head may have ridges to make it easy to turn with pliers rather than the inserted driver

|

| same as socket cap

|

socket head --- same as socket cap

|

|

spade --- you turn it with your thumb and forefinger; this is a subset of the thumb screw and has a particular name because of the shape of the head

|

|

square --- drives with a wrench or pliers; although relatively inexpensive to manufacturer, this is primarily the precursor to the hex head and has largely been replaced by that.

|

| trim screw

|

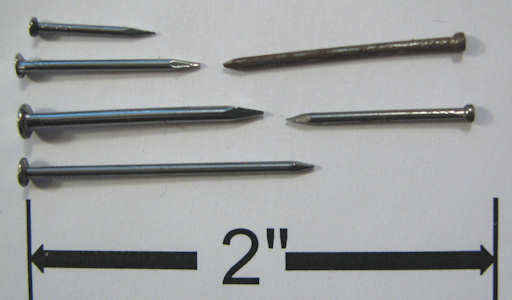

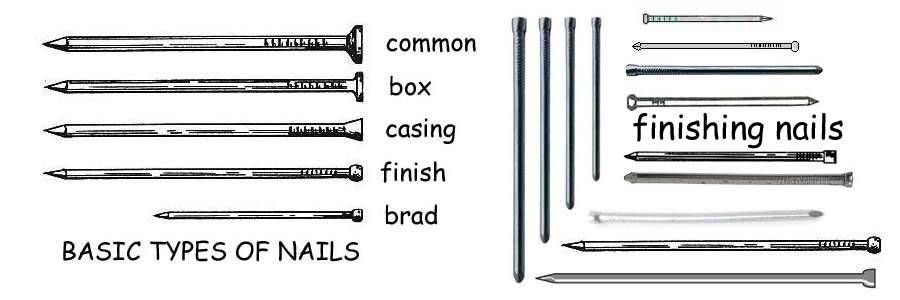

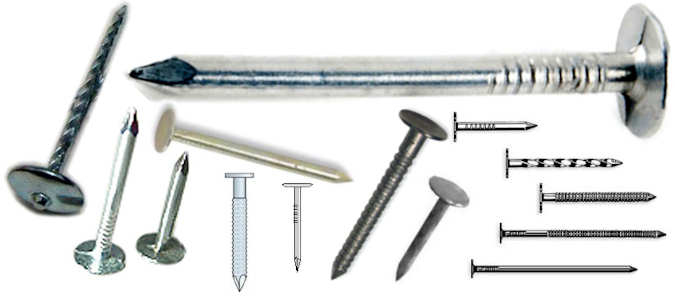

trim --- small head (the screw version of a finishing nail)

|

|

truss --- has a very shallow dome head. It also has a low edge which some definitions say is to inhibit tampering, but since they use standard drive types, that doesn't make much sense; the edge is usually low enough to prevent pliers from being used on them but nothing else. The SHAPE of the truss head is used on some security head types but items sold specifically as truss head are NOT security types. Some items sold as truss head are what would be more accurately called a round washer head (see above).

|

|

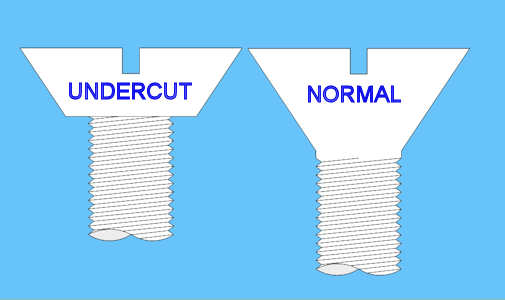

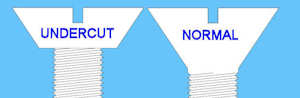

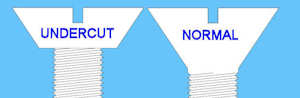

undercut --- Shallow-head countersink that provides a little extra thread length for a given screw length

|

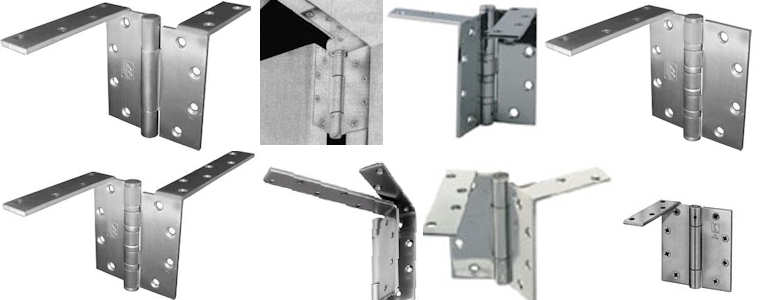

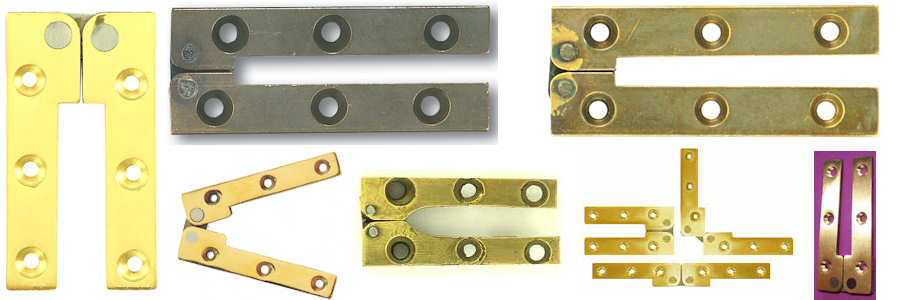

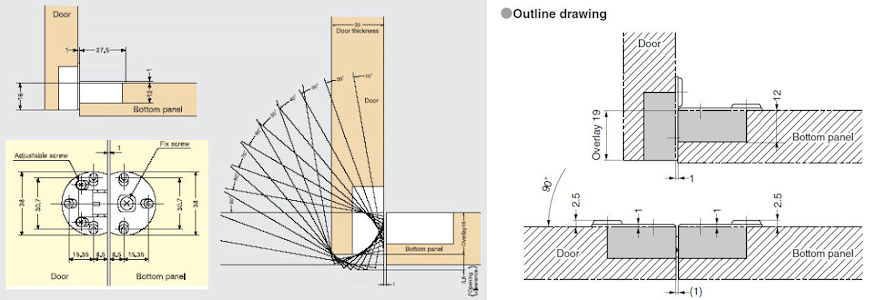

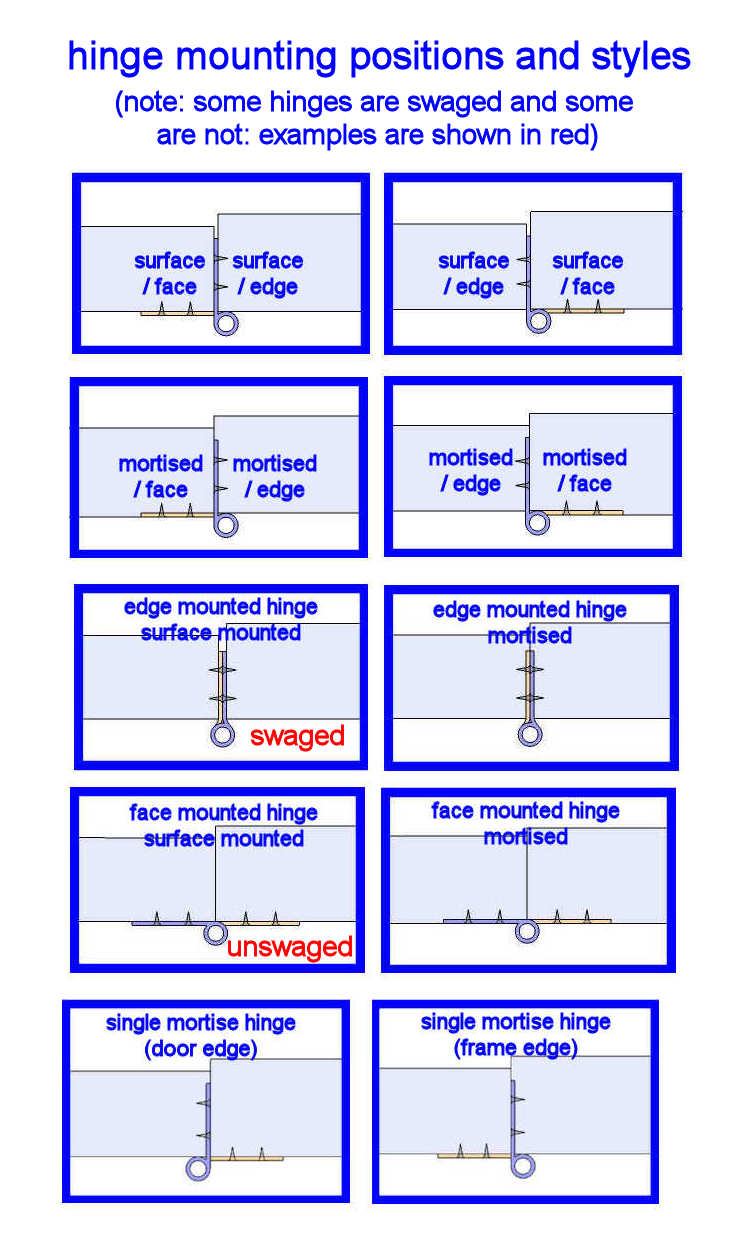

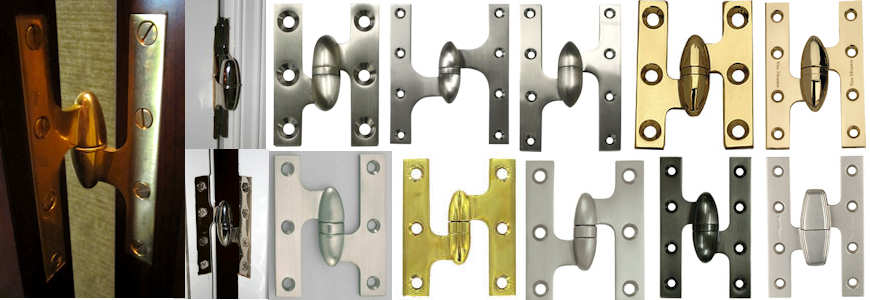

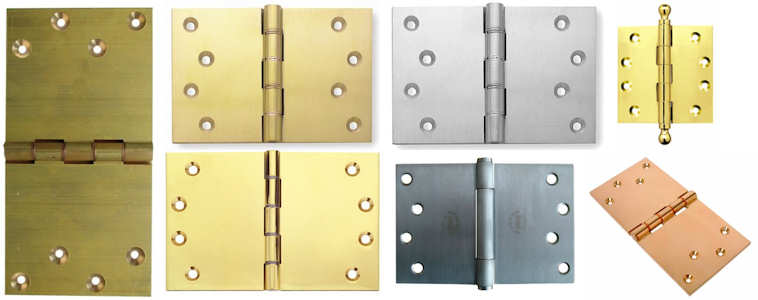

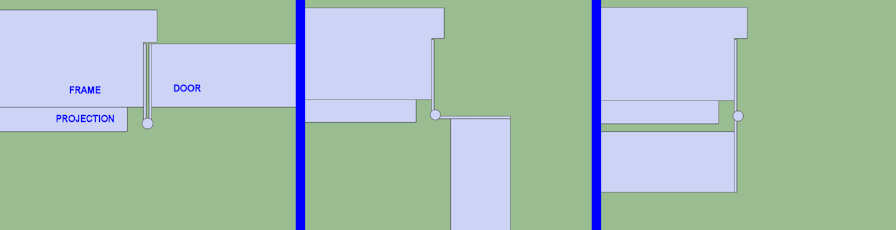

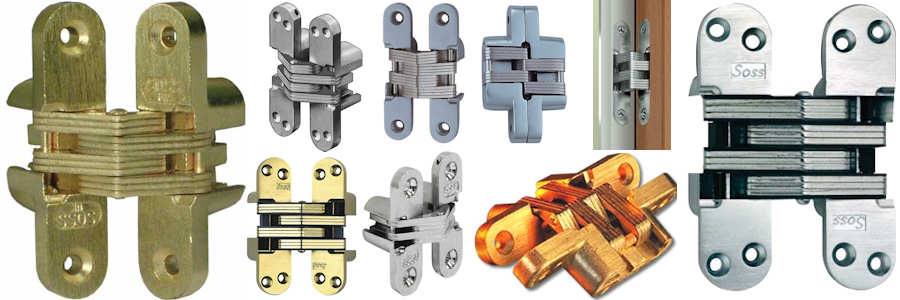

need to add flush hinge pics

need to add flush hinge pics

need to add hinge dimensions pics

need to add hinge dimensions pics need to add hinge finialpics

need to add hinge finialpics

need to add hospital tip hinge pics

need to add hospital tip hinge pics

need to add paumelle hinge pics

need to add paumelle hinge pics

need to add

need to add

need to add spring loaded hinge pics

need to add spring loaded hinge pics