open main page for all woods open page 2 for articles

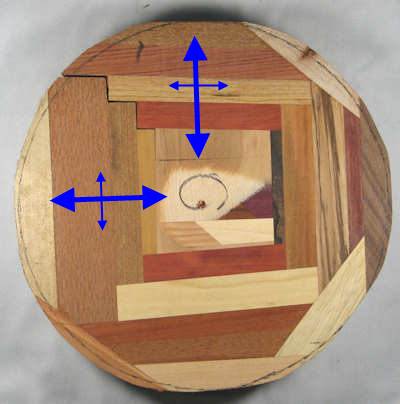

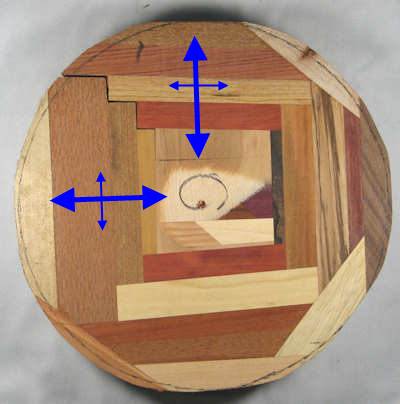

STRESS SEPARATION

A bottom view, and closeup, of a built up blank for one of my laminated bowls, with blue arrows intending to show the direction of, and by their thickness the magnitude of, the streses in the upper and left portions. The force expanding the wood across the grain is greater than that with the grain and because the jagged joint between the two sections is all wood ends at right angles, the forces have pushed the joint apart and as you would expect, the separation gets larger as you move outward because the movement, to the left and upward, of the left and right sides, is greater at the rims than at the center, where the glue joints are holding tightly enough to overcome the minor stress there.

This blank, I am sad to say, is headed for the bar-b-que pit. Sometimes this sort of thing happens, to a lesser degree, AFTER I've finished turning a bowl and finishing it and it has been sitting around for a couple of years. Below is a very extreme example of that. As you can see, it is also a separation along a joint where the woods are at right angles, or sharp angles, to each other and the separation is so large that I can fit 5 index cards into it.

Because of this problem, I no longer build up my bowl blanks with so many end-to-face joints and for the most part I now avoid this problem (but not entirely). It's painful to have to toss a bowl that I've put a dozen hours into, but so it goes ...