open main page for all woods open page 2 for articles

LUMBER DEFECTS

This page currently only presents the major distortion defects that lumber is subject to. Generically, these defects are all known as "warping", but that is a general term and what I describe here is specific TYPES of warping. Knots, gum deposits, shakes, checks and other defects will be added. The black lines show unwarped boards and the red lines show the distorted board. Although it can happen that these warping defects come in combinations, the presentation here treats each type of warp independantly. Boards with individual defects can frequently be salvaged to some extent, as discussed below, but any board with a combination of such defects is best used as firewood.

BOW

BOW

A bow is where the board warps along the grain lines such that if it were sitting "flat" on a table, the ends would be up off the table. There is no warp across the grain. Such a distortion may easily be caused by improper storage but it can also occur due to uneven air circulation during drying. A bow may happen on just one end of a board. Any bowing introduces internal stresses that may make the board difficult to cut. Ripping such boards can be dangerous and really shouldn't be done at all. Crosscutting should only be done with the bow facing upwards. Very small bows can be removed on a planer but large ones will likely require crosscutting into shorter boards and then planing to finish the flattening. With some wood, you can steam the board and flatten it at least somewhat with weights or clamping.

CROOK

CROOK

A crook is an end-to-end curve along the edge of the board such that if the board were lying flat on a table, it would continue to lie flat on the table, but it would be as though you had clamped the middle in place and then pulled both ends towards you. A crook can happen on just one end of a board. A crook can be caused by improper drying and/or seasoning or it can occur if the pith is at the edge. You can safely rip such a board to recover a narrower board, or do the same thing with multiple passes through a jointer.

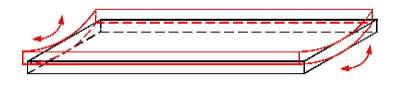

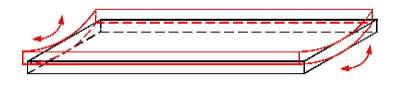

CUP

CUP

A cup is an edge-to-edge curve over the face of a board. It is moderately common on tangentially cut boards and on boards cut close to the pith and it can also occur due to uneven air circulation while drying. Sometimes a cup can be corrected by allowing the board to dry with even air flow but more often cupped boards have to be ripped into narrower boards (a bandsaw is safer for such ripping than a table saw or radial arm saw) and then planed. Or, you could take up coopering and tell everyone you cupped the board on purpose.

TWIST

TWIST

A twist is a dance craze of the 1950's. No wait ... sorry about that. A twist is uneven or irregular warping, typically where one corner of a board raises up and is not alligned with the other three. It can result from improper drying. It is more likely to occur in boards that have a grain pattern that is not parallel to the edge. Like a bow, a twist can sometimes be reduced by steaming and weighing or clamping a board, but most likely you'll just have to cut it into smaller boards while saying words that you do not encourage your children to use.

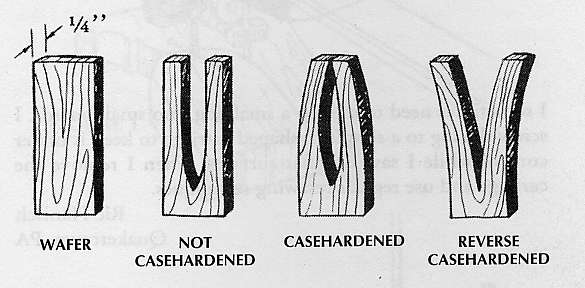

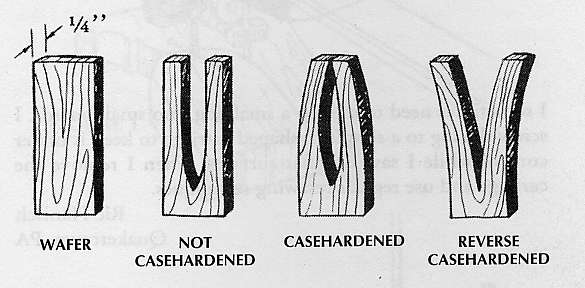

CASE HARDENING

Case hardening is a condition of internal stress in wood due most commonly to overly rapid drying and/or improper conditioning after drying. A casehardened board cannot be visually distinguished from any other board, but they can be VERY dangerous in rip-sawing, particularly with radial arm saw (ANY ripping with a RAS is somewhat dangerous). What happens is that the stresses cause the saw kerf to close up and bind against the blade on the outfeed side. On a table saw this can cause kickback and on a RAW it can cause kickback AND it can also cause the plank to rise up on the outfeed side of the cut and get chewed up instead of making a clean cut. By cutting off a small sample piece and bandsawing a long slot along the grain as shown below, you can tell whether or not a plank is case hardened, BUT ... be aware that case hardening is very localized, so testing one end of a plank doesn't tell you anything about the middle or the other end.

cut-off a wafer and then slot it with a bandsaw to see if a plank is case hardened.

BOW

BOW

CROOK

CROOK

CUP

CUP

TWIST

TWIST